A processing technology of plant fiber spunlace non-woven fabric that selectively blocks ultraviolet rays

A technology of spunlace non-woven fabrics and plant fibers, which is applied in the fields of fiber chemical characteristics, non-woven fabrics, textiles and papermaking, etc. It can solve the problem of not being able to meet the requirements of non-woven fabrics for UV protection, affecting the mechanical properties of non-woven fabrics, and preventing UV rays. Improve the effect of UV protection modification, avoid the sudden decline of UV protection performance, and enhance the adhesion rate and adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

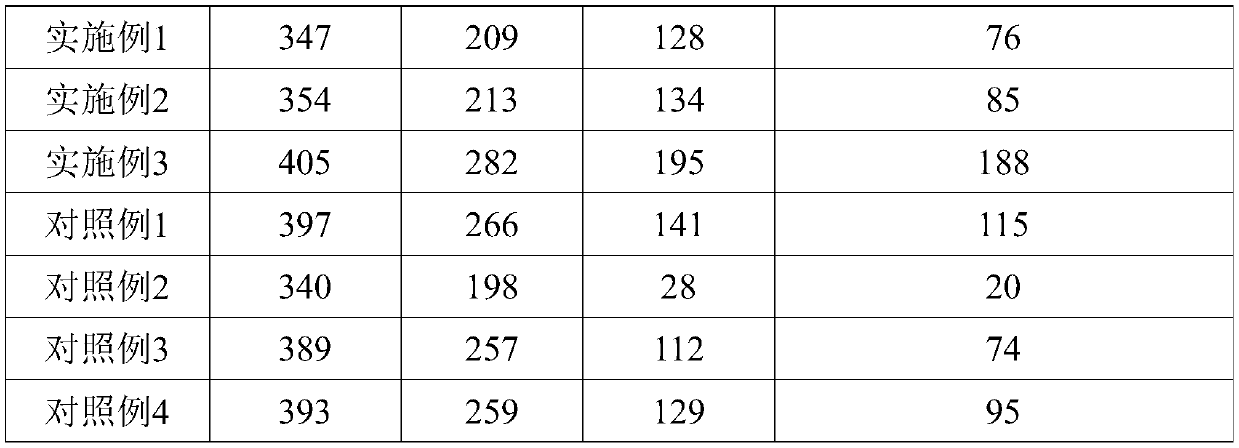

Examples

Embodiment 1

[0038] Processing of spunlace nonwovens:

[0039] (1) Pulping: first utilize the hydraulic pulper to pulverize the kapok fiber, and then use a refiner and a refiner to refine the pulp to obtain the kapok fiber slurry;

[0040] (2) Filtration and impurity removal: the prepared kapok fiber slurry is diluted with water to a mass concentration of 1%, and sent into a pulping tank through a screw pump, and then sent to the impurity removal process through a pulping pump. Filter and pressure sieve to remove impurities, and then sent to high-speed mixer through screw pump;

[0041] (3) UV modification: add UV modifier to the kapok fiber slurry after filtering and removing impurities, the consumption of UV modifier is 0.5% of the dry weight of kapok fiber, and heat up to 70-75° C. and mix at high speed for 5 minutes, Rotating speed 1300rpm, obtains modified kapok fiber slurry;

[0042] (4) Fiber web forming: the prepared modified kapok fiber slurry is sent into the secondary flushing...

Embodiment 2

[0050] Processing of spunlace nonwovens:

[0051] (1) Pulping: first utilize the hydraulic pulper to pulverize the kapok fiber, and then use a refiner and a refiner to refine the pulp to obtain the kapok fiber slurry;

[0052] (2) Filtration and impurity removal: the prepared kapok fiber slurry is diluted with water to a mass concentration of 1%, and sent into a pulping tank through a screw pump, and then sent to the impurity removal process through a pulping pump. Filter and pressure sieve to remove impurities, and then sent to high-speed mixer through screw pump;

[0053] (3) UV modification: add UV modifier to the kapok fiber slurry after filtering and removing impurities, the consumption of UV modifier is 0.5% of the dry weight of kapok fiber, and heat up to 70-75° C. and mix at high speed for 5 minutes, Rotating speed 1300rpm, obtains modified kapok fiber slurry;

[0054] (4) Fiber web forming: the prepared modified kapok fiber slurry is sent into the secondary flushing...

Embodiment 3

[0062] Processing of spunlace nonwovens:

[0063] (1) Pulping: first utilize the hydraulic pulper to pulverize the kapok fiber, and then use a refiner and a refiner to refine the pulp to obtain the kapok fiber slurry;

[0064] (2) Filtration and impurity removal: the prepared kapok fiber slurry is diluted with water to a mass concentration of 1%, and sent into a pulping tank through a screw pump, and then sent to the impurity removal process through a pulping pump. Filter and pressure sieve to remove impurities, and then sent to high-speed mixer through screw pump;

[0065] (3) UV modification: add UV modifier to the kapok fiber slurry after filtering and removing impurities, the consumption of UV modifier is 0.5% of the dry weight of kapok fiber, and heat up to 70-75° C. and mix at high speed for 5 minutes, Rotating speed 1300rpm, obtains modified kapok fiber slurry;

[0066] (4) Fiber web forming: the prepared modified kapok fiber slurry is sent into the secondary flushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com