Process for preparing acrolein by glycerin dewatering

A technology of acrolein and glycerin, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of only the highest yield of acrolein, high content of hydroxyacetone, and low yield of acrolein, etc. To achieve the effect of recyclable equipment corrosion, low production cost and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Silicate zeolite MCM-49 was synthesized by hydrothermal crystallization method. The original powder was exchanged with 2mol / L ammonium nitrate solution at 85°C for 6h, filtered and washed by suction, and repeated 3 times. The obtained filter cake was dried at 120°C and calcined at 540°C for 3 hours to obtain H-MCM-49 zeolite with Si / Al=25, and then tabletted, crushed and sieved to obtain 40-60 mesh zeolite catalyst particles.

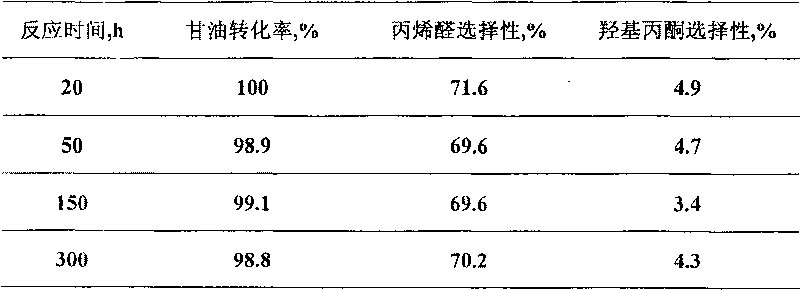

[0019] Load the catalyst in the fixed bed continuous flow reaction device, and use the pump to continuously send the raw glycerin aqueous solution into the reactor respectively. The reaction temperature is 360 ° C, the glycerin is 20 wt% aqueous solution, the reaction pressure is normal pressure, and the liquid hourly space velocity is 1.7 h -1 , the reaction results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2-5

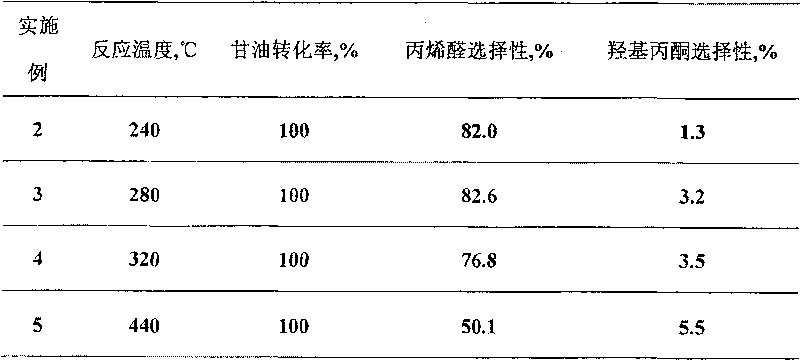

[0023] Catalyst and reaction condition are the same as embodiment 1, only change temperature of reaction, and reaction result is as table 2.

[0024] Table 2

[0025]

Embodiment 6-7

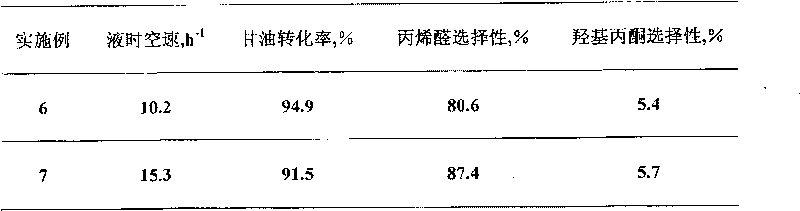

[0027] Catalyst and reaction condition are the same as embodiment 1, only change liquid hourly space velocity, and reaction result is as table 3.

[0028] table 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com