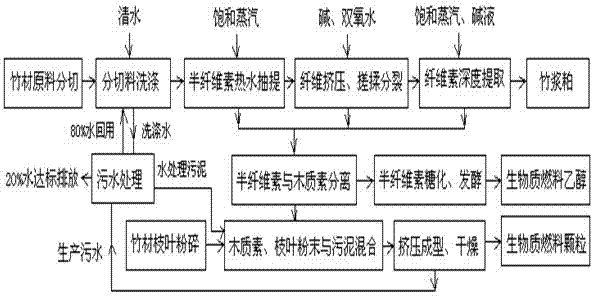

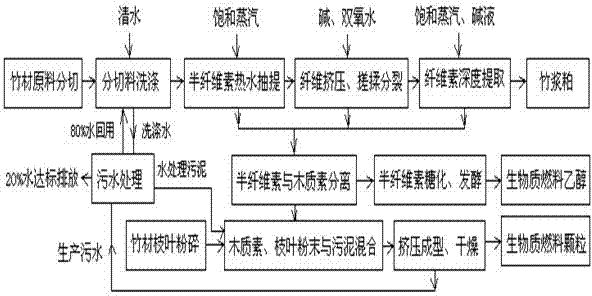

Co-production preparation method of bamboo biomass fuel and bamboo pulp

A biomass fuel, bamboo pulp technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the high investment and operation cost of sewage treatment equipment, bamboo tail and branches and leaves are not effectively used, increase resources and environmental load, etc. problems, to increase the consumption of chemicals, avoid the requirements of chemical corrosion resistance, and reduce the yield of cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Extraction of hemicellulose

[0024] Cut the bamboo raw material into pieces with a length of 20mm, wash with clean water to remove sand and dust, put it in a pot according to the liquid-solid ratio of 3:1, heat it up to 155°C, and keep it warm for 120 minutes, then carry out hot water extraction and hydrolysis of semi-fiber Using a sieve to filter the hemicellulose-containing extract from the sheet material under normal pressure to obtain the hemicellulose extract liquid and the hydrolyzed sheet material;

[0025] (2) Cellulose extrusion, kneading and splitting

[0026] Use a parallel twin-screw extruder to apply an extrusion pressure greater than 1 MPa to the hydrolyzed sheet material in step (1), and control the friction temperature to 90°C. Squeeze and knead with a compression ratio of 4:1 to make the sheet material into a filament material, and extrude the hemicellulose and lignin extract to obtain the remaining filament material, and then to the remaining fil...

Embodiment 2

[0034] (1) Extraction of hemicellulose

[0035] Cut the bamboo raw material into pieces with a length of 25mm, wash with clean water to remove sand and dust, put it in a pot according to the liquid-solid ratio of 3:1, heat it up to 160°C, keep it warm for 130 minutes, and carry out hot water extraction and hydrolysis of semi-fiber Using a sieve to filter the hemicellulose-containing extract from the sheet material under normal pressure to obtain the hemicellulose extract liquid and the hydrolyzed sheet material;

[0036] (2) Cellulose extrusion, kneading and splitting

[0037] Use a parallel twin-screw extruder to apply an extrusion pressure greater than 1 MPa to the hydrolyzed sheet material in step (1), and control the friction temperature to 100°C. Squeeze and knead with a compression ratio of 4:1 to make the flake material into a filamentous material. After extruding the hemicellulose and lignin extract, the remaining filamentous material is poured into the remaining fila...

Embodiment 3

[0045] (1) Extraction of hemicellulose

[0046] Cut bamboo raw materials into slices with a length of 30mm, wash with clean water to remove sand and dust, put them in a pot according to the liquid-solid ratio of 3:1, heat up to 155°C, keep warm for 200 minutes, and carry out hot water extraction and hydrolysis of semi-fiber Using a sieve to filter the hemicellulose-containing extract from the sheet material under normal pressure to obtain the hemicellulose extract liquid and the hydrolyzed sheet material;

[0047] (2) Cellulose extrusion, kneading and splitting

[0048] Use a parallel twin-screw extruder to apply an extrusion pressure greater than 1 MPa to the hydrolyzed sheet material in step (1), and control the friction temperature to 120°C; extrude and knead with a compression ratio of 4:1 to make the sheet material Become a filamentous material, extrude the hemicellulose and lignin extract to obtain the remaining filamentous material; add 2% alkali and 4% hydrogen peroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com