Magnetic oxide supporting active carbon catalytic microwave degradation method of surfactant

A technology of magnetic oxides and surfactants, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Degradation, sludge activity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

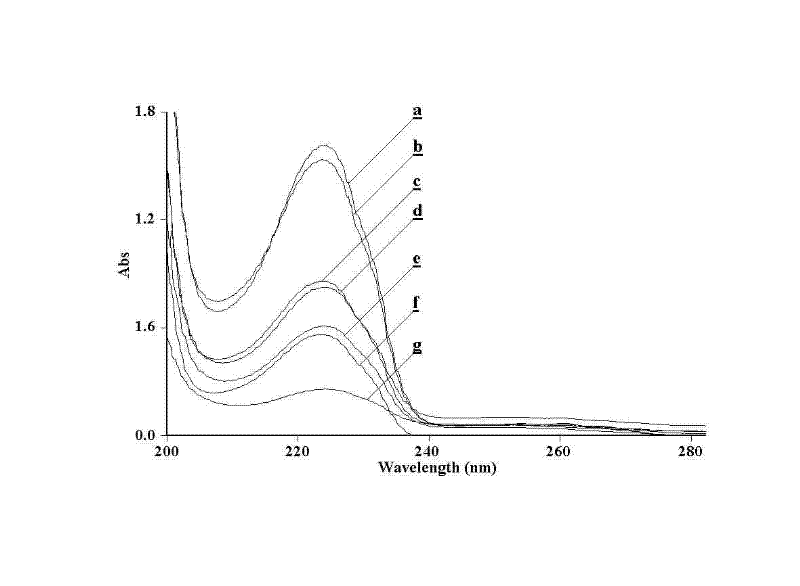

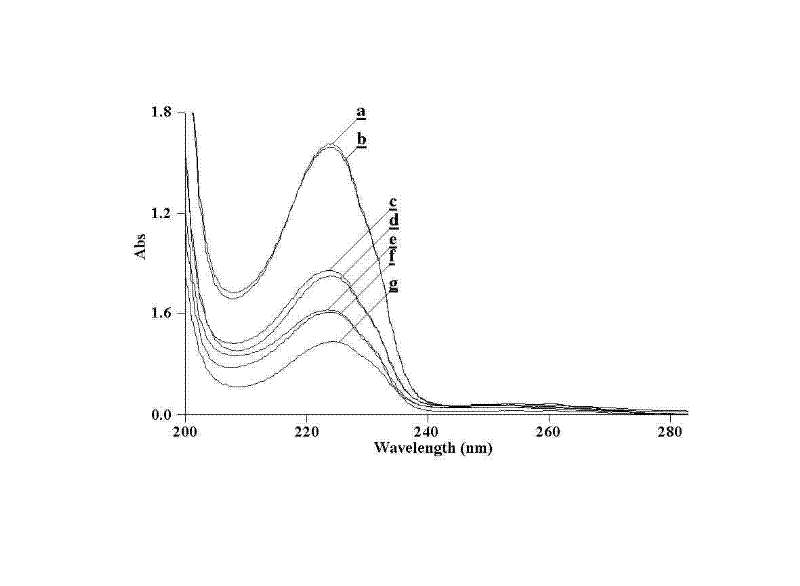

Image

Examples

Embodiment 1

[0043] Example 1 Method for Catalyzed Microwave Degradation of Sodium Dodecylbenzene Sulfonate by Iron Oxide Loaded Activated Carbon

[0044] Preparation of iron oxide-loaded activated carbon catalyst: crush the activated carbon and sieve it through a 100-mesh sieve, weigh 10 g of activated carbon powder, put it into 300 mL of deionized water and boil for 30 min, then filter after cooling, repeat the operation three times, and dry it for later use. A certain amount of dried activated carbon powder was weighed and impregnated in 0.2 mol / L Fe(NO 3 ) 3 solution, magnetically stirred for 12.0 h, filtered off the supernatant, washed the sediment with deionized water until neutral, dried at 105°C for 6.0 h, then put it into a muffle furnace and calcined at 300°C for 3.0 h, cooled to room temperature, The iron oxide-loaded activated carbon catalyst is obtained, which is put into a desiccator for subsequent use.

[0045] Microwave degradation: Take 25.0 mL of SDBS solution with a co...

Embodiment 2

[0051] Example 2 Method for Microwave Degradation of Sodium Dodecylbenzene Sulfonate Catalyzed by Nickel Oxide Supported Activated Carbon

[0052] Preparation of nickel oxide-supported activated carbon catalyst: crush the activated carbon and sieve it through a 100-mesh sieve, weigh 10 g of activated carbon powder, put it into 300 mL of deionized water, boil for 30 min, cool and filter, repeat the operation three times, and dry it for later use. A certain amount of dried activated carbon powder was weighed and impregnated in 0.2 mol / L Ni(NO 3 ) 2 solution, magnetically stirred for 12.0 h, filtered the supernatant, washed the sediment with deionized water until neutral, put it in a constant temperature drying oven to dry for 6.0 h, then put it in a muffle furnace for calcination at 300 °C for 3.0 h, and cooled to At room temperature, the nickel oxide-supported activated carbon catalyst was obtained and put into a desiccator for subsequent use.

[0053] Microwave degradation: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com