Knitting machine and method for producing knitted fabrics from rovings

A technology for knitting machines and knitwear, which is applied in the field of knitting machines to prevent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

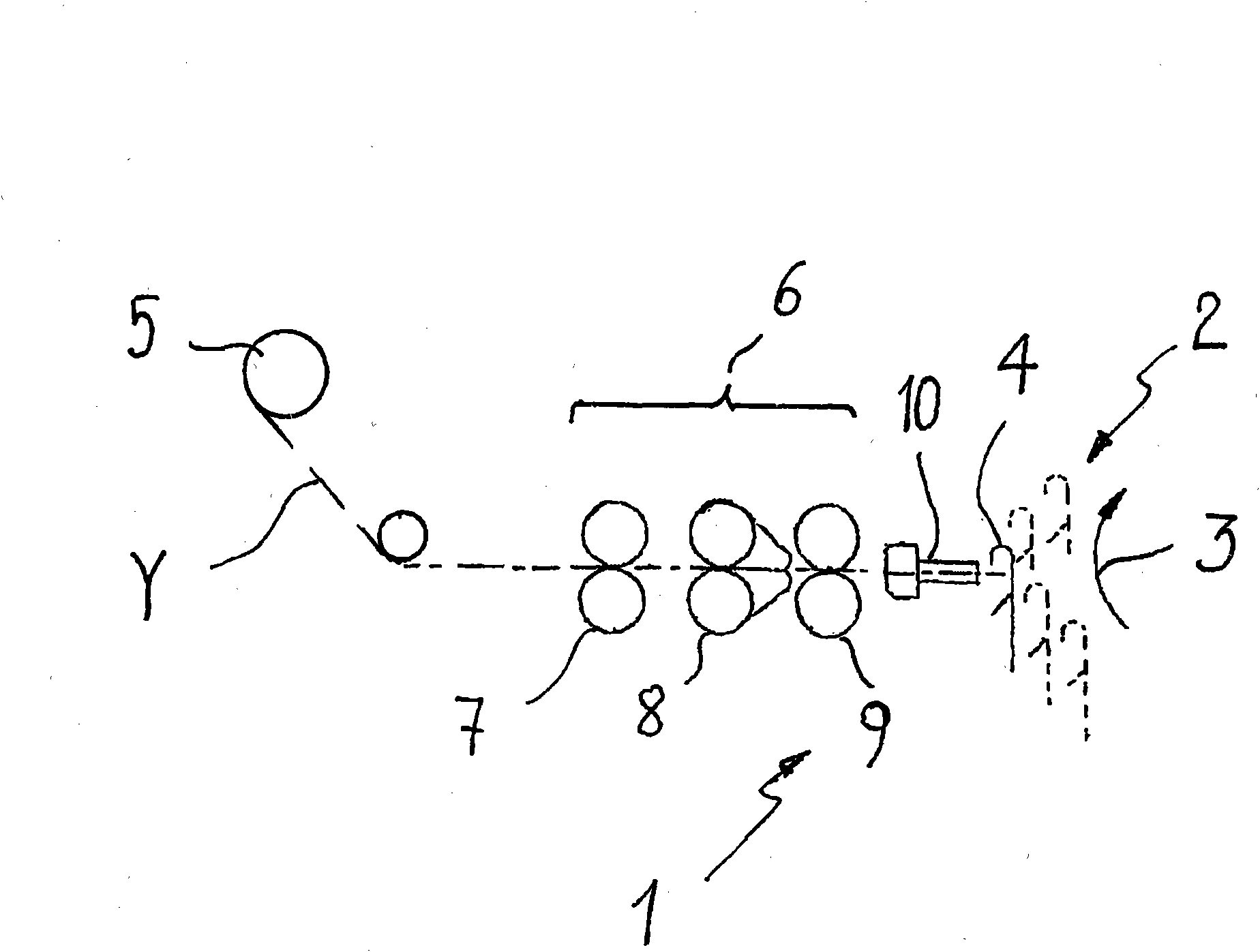

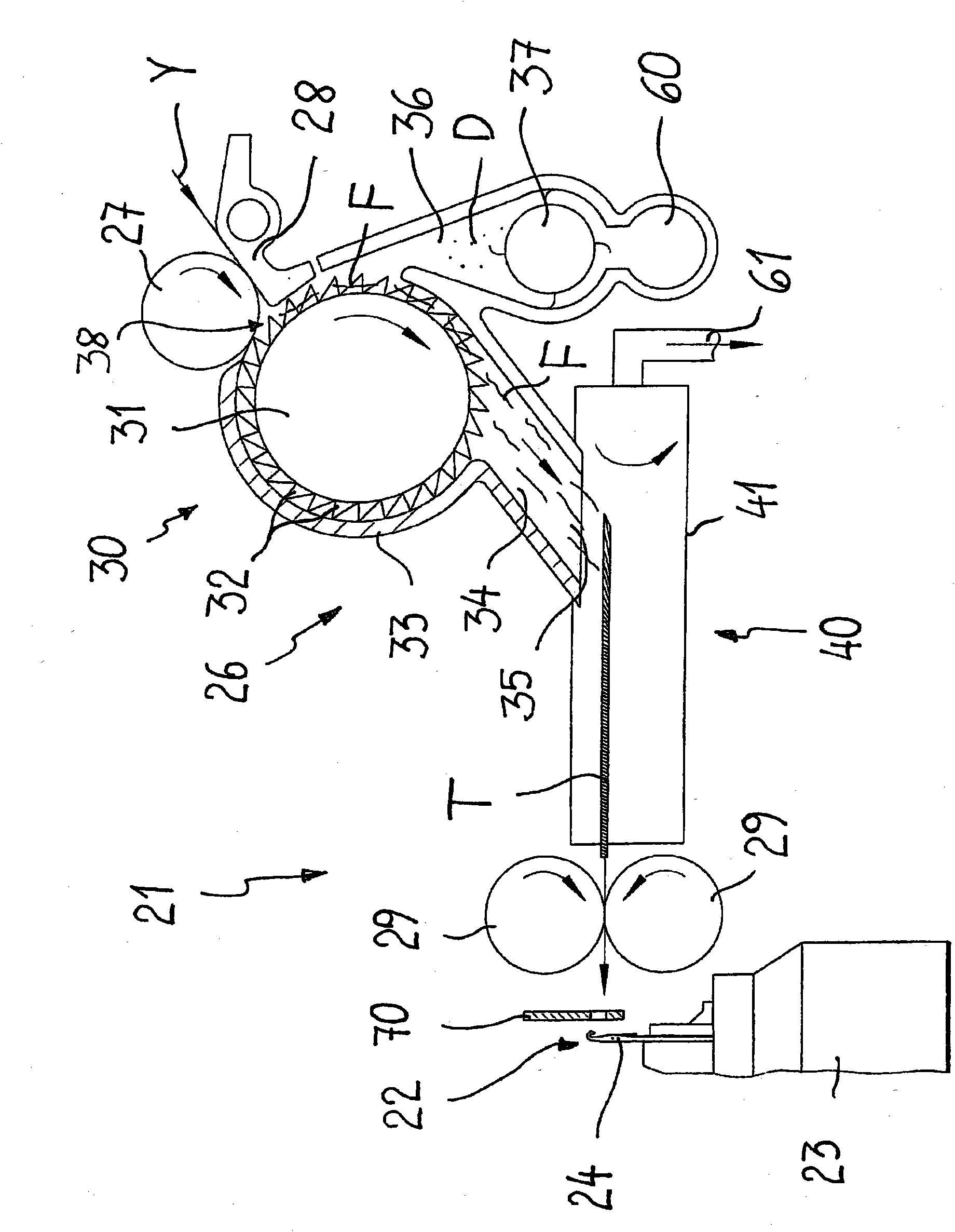

[0039] FIG. 1 schematically shows the principle of a prior art circular knitting machine equipped with a drawing system in order to be able to manufacture knitwear directly from rovings. The circular knitting machine is denoted as a whole by the reference numeral 1 and has a needle cylinder 3 on which, for example, 48 or 96 knitting points with movable needles 4 , in particular latch needles, are arranged. The needles 4 directly process the roving Y which is supplied to the knitting point 2, for example as a drafted sliver from a tank or as a flyer roving from a flyer bobbin 5 which can be mounted on the circular knitting machine 1 in the bobbin holder. In this case, the knitting point 2 is considered to be the point at which the fiber strip Y is conveyed to the knitting needles 4 arranged on the needle cylinder 3 .

[0040] The circular knitting machine 1 is preceded by a drawing system 6 in which the roving Y is drawn to a desired fineness into a fiber sliver. Only a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com