Polyarylene sulfide resin composition and fluid pipe material

A technology of resin composition and polyarylene sulfide, which is applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., which can solve the problems of reduced heat resistance, weakened joint force of formed pipelines, increased creep deformation, etc. , to achieve the effect of inhibiting breakage, small elongation and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

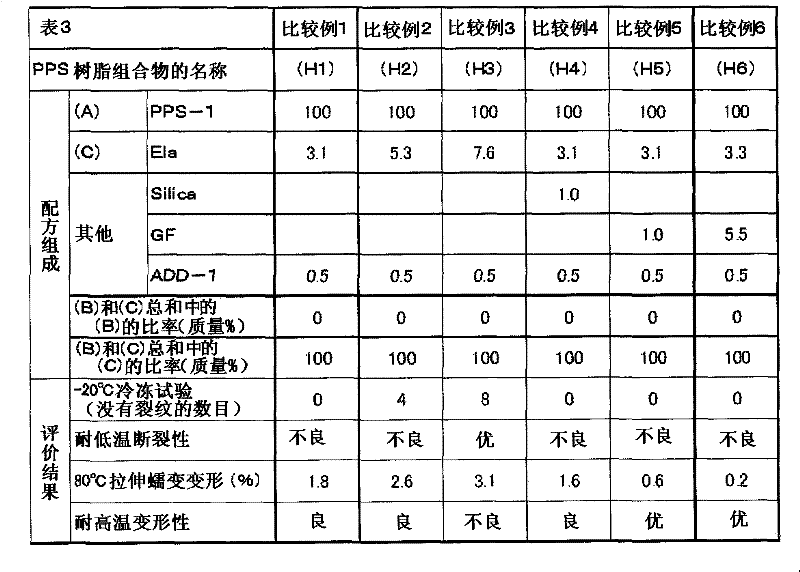

Examples

preparation example Construction

[0060] As the preparation method of the PAS resin composition of the present invention, for example, the following method can be mentioned: PAS resin (A), metal particles (B) containing at least one metal species selected from copper, nickel and zinc, and thermoplastic elastomer The body (C) is mixed in advance with a Henschel mixer or a drum mixer, and then supplied to a single-screw or twin-screw extrusion kneader, etc., and kneaded at 200°C to 360°C, Then pelletized to obtain a PAS resin composition. It is particularly preferable to use a twin-screw extrusion kneader rotating in the same direction provided with kneading discs for kneading. In addition, after granulation, processing such as annealing treatment, UV irradiation, and plasma irradiation may be performed.

[0061] The fluid piping member of the present invention obtained by molding the aforementioned PAS resin composition can be used in a wide temperature range with little deformation, and thus can be used for v...

Embodiment

[0067] Hereinafter, the present invention will be further described with reference to examples. In addition, the peak molecular weight and melt viscosity of the PAS resin obtained in the following manufacture example were measured by the following method.

[0068] [Determination of peak molecular weight]

[0069] The peak molecular weight of the PAS resin was measured by gel permeation chromatography using six types of monodisperse polystyrenes for calibration under the following measurement conditions.

[0070] Apparatus: Ultra-high temperature polymer molecular weight distribution measurement apparatus (manufactured by Senshu Scientific co., ltd. "SSC-7000")

[0071] Column: UT-805L (manufactured by Showa Denko Co., Ltd.)

[0072] Column temperature: 210°C

[0073] Solvent: 1-Chlorinated Naphthalene

[0074] Measuring method: UV detector (360nm)

[0075] [Measurement of Melt Viscosity]

[0076] Using a capillary rheometer, at a temperature of 300°C and a shear rate of ...

manufacture example 1

[0077] (Production example 1) Production of PAS resin (A) (PPS-1)

[0078]At room temperature, add 1838kg (12.5 kilomoles) of p-dichloro Benzene (hereinafter, referred to as "p-DCB" for short.), 4958kg (50 kilomoles) of N-methylpyrrolidone (hereinafter, referred to as "NMP" for short.), 90kg (5.0 kilomoles) of water, were stirred in a nitrogen atmosphere It takes 20 minutes to raise the temperature to 100°C, close the system, and then raise the temperature to 220°C in 40 minutes. At this temperature, the internal pressure is controlled to 0.22MPa, and 1500kg Na is added dropwise in 3 hours. 2 S·xH 2 O, 225kgNaSH·yH 2 O, the mixed solution of 425kg water (Na 2 S: 11.4 kilomoles, NaSH: 3.2 kilomoles, 50.3% by mass of water). During the dropwise addition, the dehydration operation was carried out simultaneously, and the water was removed from the system, and the p-DCB distilled out together with the water was continuously returned to the autoclave. It should be noted that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com