Enhanced AlGaN/GaN HEMT (High Electron Mobility Transistor) device and manufacturing method thereof

An enhancement type, device technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of poor performance of GaN integrated circuits, difficult to accurately control the thickness of the AlGaN barrier layer in the gate region, and damage to AlGaN/GaN heterogeneity. junction interface characteristics and other issues, to achieve the effect of simple and controllable process and small gate leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

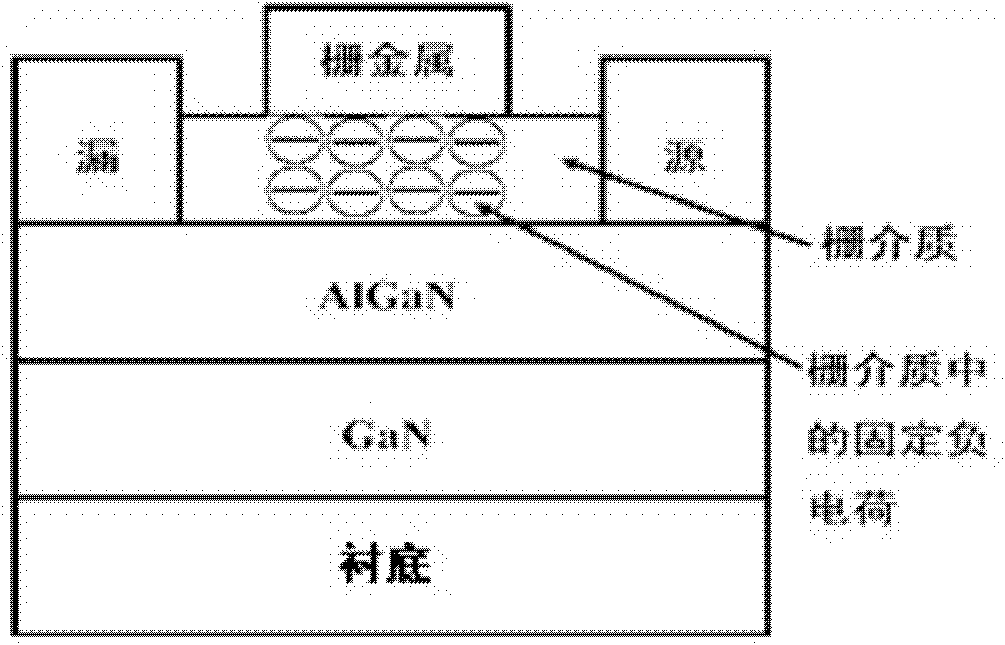

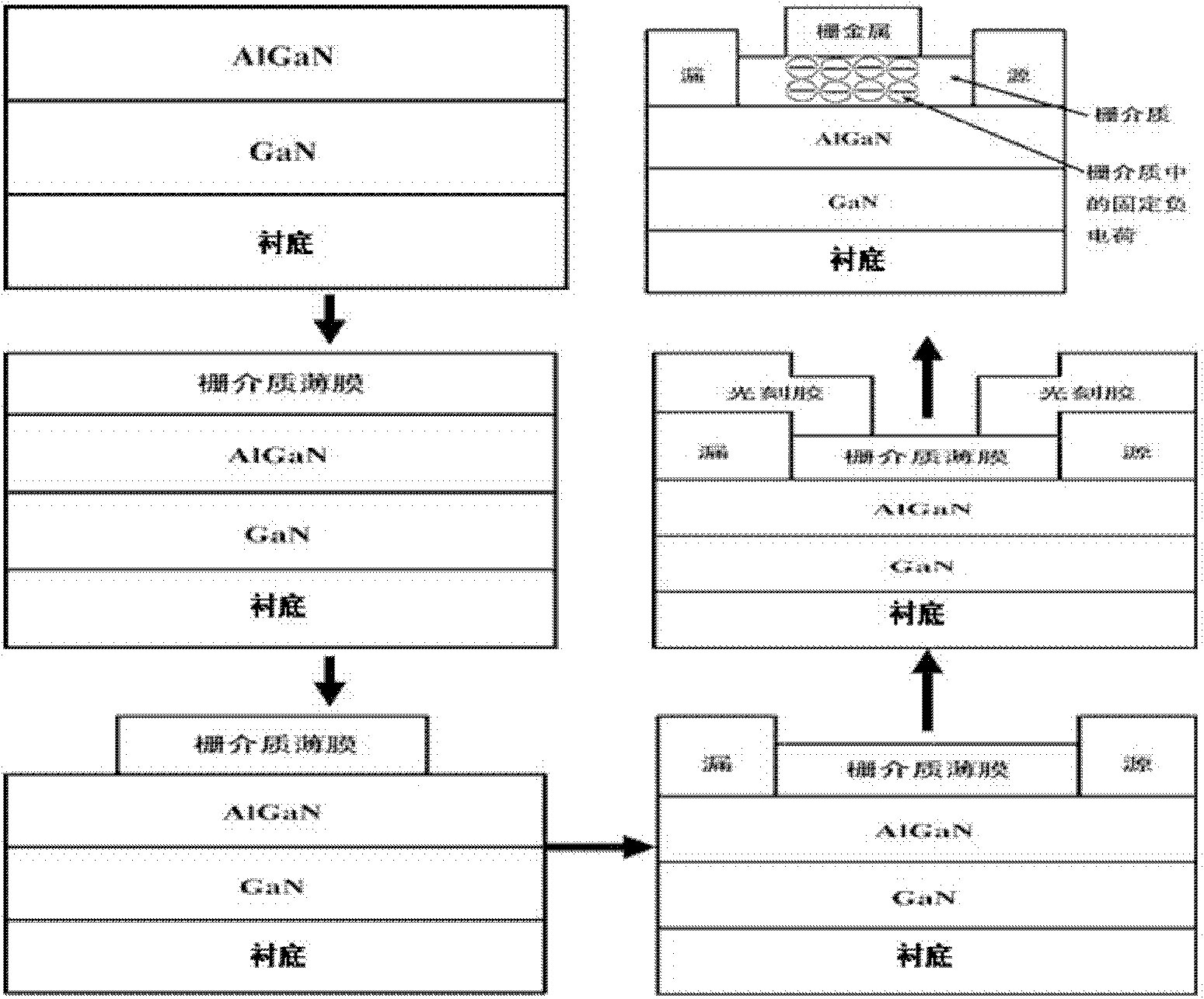

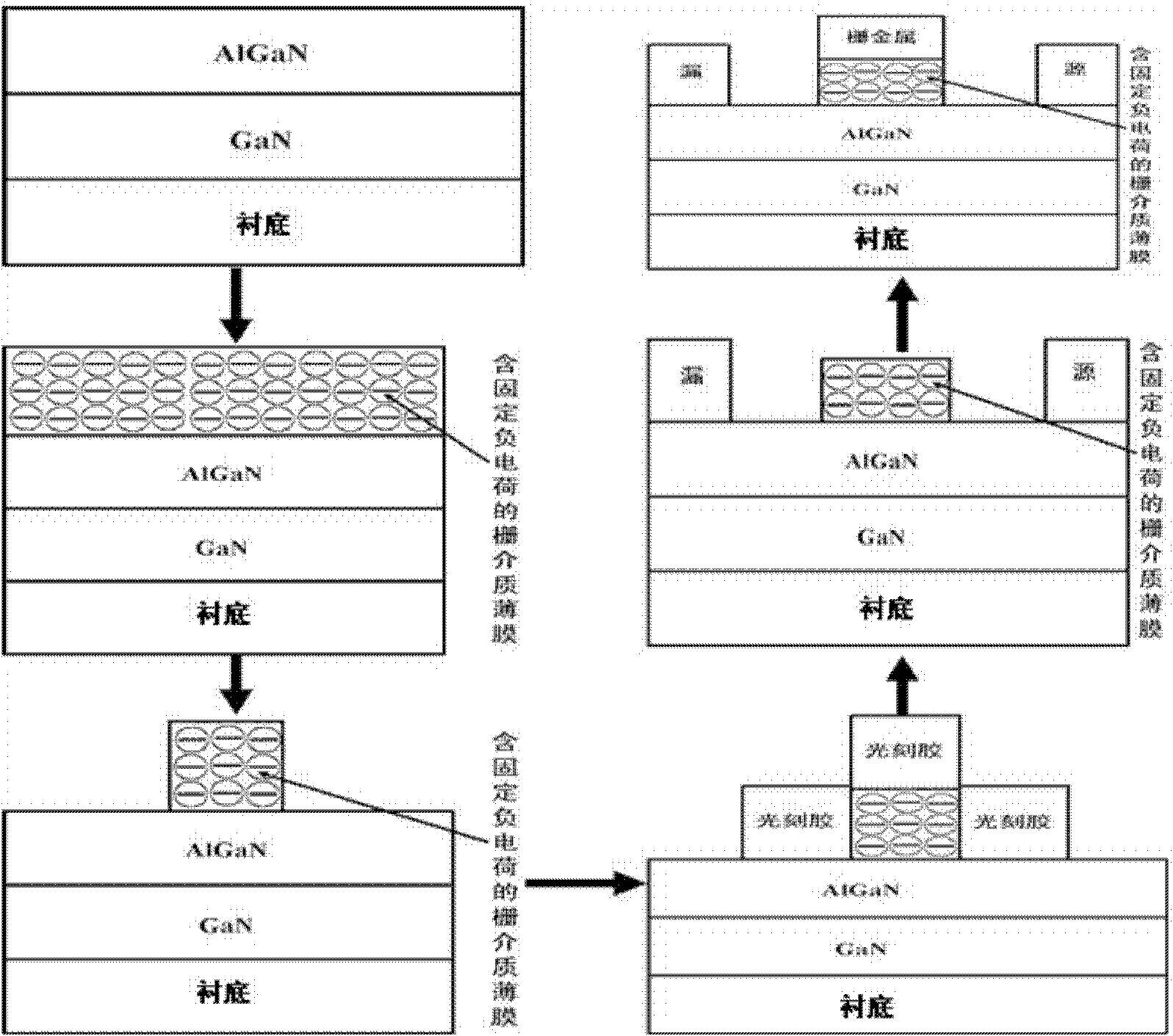

[0045] Using the present invention as figure 2 The process flow shown, using F ion-implanted Al 2 o 3 (hereinafter abbreviated as: F: Al 2 o 3 ) film as the gate dielectric enhancement mode AlGaN / GaN HEMT device, the schematic diagram of the device structure is shown in Figure 6 shown. Its specific implementation is as follows:

[0046] (1), first prepare AlGaN / GaN heterojunction material on sapphire substrate, and then use molecular beam epitaxy (MBE) to deposit a layer of about 10nm thick Al on the surface of AlGaN / GaN heterojunction material 2 o 3 film.

[0047] (2), covered with Al 2 o 3 The surface of the thin-film AlGaN / GaN heterojunction material is spin-coated with photoresist, and the positions of the source region (Source) and the drain region (Drain) are positioned by photolithography, and then the source region and the drain region are positioned with a 1:100 HF solution. Al 2 o 3 The film is etched away. Electron beam evaporation technology is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com