High-performance EPDM (ethylene-propylene-diene monomer)/PPTA (poly (p-phenylene terephthalamide))-pulp composite material and preparation method thereof

A composite material, high-performance technology, applied in the field of high-performance EPDM/PPTA-pulp composite material and its preparation, to solve the difficulty of feeding and solve the effect of harsh environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 2

[0054] The mass percentage of raw materials is: EPDM 60%, aramid pulp composite matrix 15%, white carbon black 20%, dicumyl peroxide 3%, 2,2,4-trimethyl-1,2-dihydroquinone 1% morphine polymer, 1% 2,2'-dithiodibenzothiazole.

Embodiment 2

[0056] Example 3

[0057] The mass percentage of raw materials is: EPDM 60%, aramid pulp composite matrix 20%, white carbon black 15%, dicumyl peroxide 3%, 2,2,4-trimethyl-1,2-dihydroquinone 1% morphine polymer, 1% 2,2'-dithiodibenzothiazole.

Embodiment 3

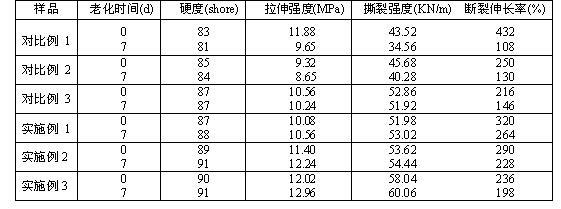

[0059] Attached Table 1 Mechanical properties of vulcanizates before and after heat aging at 150°C

[0060]

[0061] It can be seen from Table 1 that after adding a certain amount of pretreated PPTA-pulp to EPDM, the hardness and tear strength of the composite material are greatly improved, and the increase rate is also higher than that of adding the same amount of untreated PPTA-pulp. When the rayon pulp came, especially the tear strength of Example 2 reached 53.62, which was increased by nearly 23% than when no pulp was added, and 18% more than that of Comparative Example 2; the composite material (Comparative Example 1- 3) After hot air aging conditions: 150℃×7d aging, the mechanical properties decreased to varying degrees, among which the elongation at break decreased the most, and the elongation at break in Comparative Example 1 decreased by 75%; After the EPDM / PPTA-pulp composite material of zinc methacrylate (Example 1-3) was aged under the hot air aging condition: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com