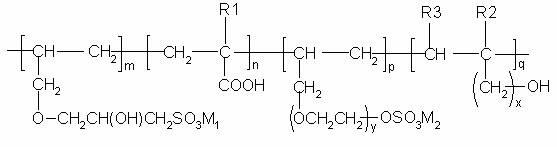

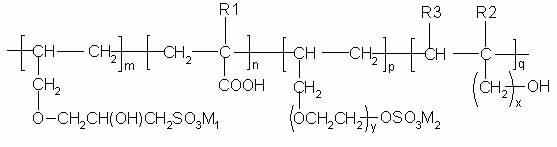

Mineral dispersant and preparation method thereof

A dispersant and mineral technology, applied in the field of mineral dispersant and its preparation, can solve the problems of weakened dispersion effect, too many free dispersants, and large volatilization loss, so as to reduce the polydispersity coefficient, improve the system stability, and improve the The effect of dispersing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of initiator aqueous solution: Weigh 176 kg of ammonium persulfate and dissolve in 352 kg of deionized water.

[0047] 2) Preparation of alkenyl carboxylic acid aqueous solution: Weigh 1000kg of acrylic acid into the reaction kettle, add 100kg of water, start stirring and refrigerated circulating water in the jacket, add 86kg of 32% liquid alkali dropwise, and stir for 30 minutes after the drop is completed.

[0048]3) Put 1200kg of water and 2-hydroxy-3-allyloxy-1-propylsulfonate into a jacketed stainless steel autoclave equipped with a reflux condenser, a pressurized constant-speed injection pump, and a jacketed stainless steel autoclave that can be raised and lowered in temperature Acid 560kg, allyl polyoxyethylene (10) sulfonic acid 1360kg, propylene alcohol 14kg, sealed autoclave. After removing the air by replacing with nitrogen, raise the temperature to 95°C, use two pressurized constant-speed syringe pumps to add the initiator aqueous solution and...

Embodiment 2

[0050] 1) Preparation of initiator aqueous solution: Weigh 122kg of potassium persulfate and dissolve it in 244kg of deionized water.

[0051] 2) Preparation of alkenyl carboxylic acid aqueous solution: Weigh 1300kg of methacrylic acid into the reaction kettle, add 130kg of water, start stirring and the refrigerated circulating water in the jacket, add dropwise 94kg of 32% liquid caustic soda, and stir for 30 minutes after the dropping.

[0052] 3) Put 1200kg of water and 2-hydroxy-3-allyloxy-1-propylsulfonate into a jacketed stainless steel autoclave equipped with a reflux condenser, a pressurized constant-speed injection pump, and a jacketed stainless steel autoclave that can be raised and lowered in temperature 350kg of sodium nitrate, 1400kg of allyl polyoxyethylene (12) sulfonic acid, 12kg of cis-3-hexenol, and a closed autoclave. After removing the air by replacing with nitrogen, raise the temperature to 95°C, use two pressurized constant-speed syringe pumps to add the i...

Embodiment 3

[0054] 1) Preparation of initiator aqueous solution: Weigh 404kg of 50% hydrogen peroxide and dissolve in 202kg of deionized water.

[0055] 2) Preparation of alkenyl carboxylic acid aqueous solution: Weigh 1200kg of acrylic acid into the reaction kettle, add 120kg of water, start stirring and refrigerated circulating water in the jacket, add dropwise 95kg of 32% liquid caustic soda, and stir for 30 minutes after dropping.

[0056] 3) Put 1200kg of water and 2-hydroxy-3-allyloxy-1-propylsulfonate into a jacketed stainless steel autoclave equipped with a reflux condenser, a pressurized constant-speed injection pump, and a jacketed stainless steel autoclave that can be raised and lowered in temperature Acid 480kg, allyl polyoxyethylene (8) ammonium sulfonate 1200kg, 2-methacryl alcohol 6kg, sealed autoclave. After removing the air by replacing with nitrogen, raise the temperature to 95°C, use two pressurized constant-speed syringe pumps to add the initiator aqueous solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com