Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

A technology of lithium-ion batteries and nanofibers, which is applied in battery electrodes, nanotechnology, fiber processing, etc., can solve the problems of poor electrode cycle stability, improve electrochemical cycle stability, simplify the preparation process, and alleviate volume changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A lithium ion battery anode material ZnFe 2 O 4 / C Nanofiber preparation method, the preparation method includes the following steps:

[0021] a) Dissolve polyacrylonitrile and polymethyl methacrylate in N,N-dimethylformamide at a mass ratio of 1:1, and stir magnetically to obtain a polymer solution;

[0022] b) Dissolve ferric nitrate and zinc acetate in the polymer solution prepared above in the ratio of Fe element: Zn element = 1:2, and magnetically stir for 10 hours to obtain a uniform spinning solution;

[0023] c) Pass the spinning solution through the electrospinning device, and spin under the conditions of a pump flow rate of 2ml / h, a voltage of 28KV, and a distance between the syringe needle and the receiving plate of 20cm to obtain precursor nanofibers.

[0024] d) Dry the precursor in a drying box at 70°C for 10 hours, raise it to 250°C at 0.5°C / min in an air atmosphere, and keep it at 250°C for 2 hours; then at 2°C in an argon atmosphere / min to 600°C, keep it at 60...

Embodiment 2

[0026] A lithium ion battery anode material ZnFe 2 O 4 / C Nanofiber preparation method, the preparation method includes the following steps:

[0027] a) Dissolve polystyrene and polymethyl methacrylate in N,N-dimethylformamide at a mass ratio of 1:4, and stir magnetically to obtain a polymer solution;

[0028] b) Dissolving iron acetylacetonate and zinc chloride in the polymer solution prepared above at the ratio of Fe element: Zn element = 1:2, and magnetically stirring for 12 hours to obtain a uniform spinning solution;

[0029] c) Pass the spinning solution through the electrospinning device, and spin under the conditions of a pump flow rate of 2ml / h, a voltage of 28KV, and a distance between the syringe needle and the receiving plate of 20cm to obtain precursor nanofibers.

[0030] d) Dry the precursor in a drying box at 90°C for 10 hours, raise it to 250°C at 0.5°C / min in an air atmosphere, and keep it at 250°C for 6 hours; then at 2°C in an argon atmosphere / min to 1000°C, keep ...

Embodiment 3

[0032] In this example, the anode material ZnFe of lithium ion battery was prepared 2 O 4 The method of / C nanofiber is:

[0033] a) Accurately weigh 0.558 g of polyacrylonitrile and 1.118 g of polymethyl methacrylate and dissolve them in 10 ml of N,N-dimethylformamide, stir magnetically to obtain a polymer solution with a mass fraction of 12%;

[0034] b) Weigh 0.353 g of iron acetylacetonate and 0.12 g of zinc acetate and dissolve in the polymer solution prepared above, magnetically stir for 12 hours to obtain a uniform spinning solution;

[0035] c) Pass the spinning solution through the spinning device, and spin it under the conditions of a pump flow rate of 2ml / h, a voltage of 28KV, and a distance between the syringe needle and the receiving plate of 20cm to obtain precursor nanofibers.

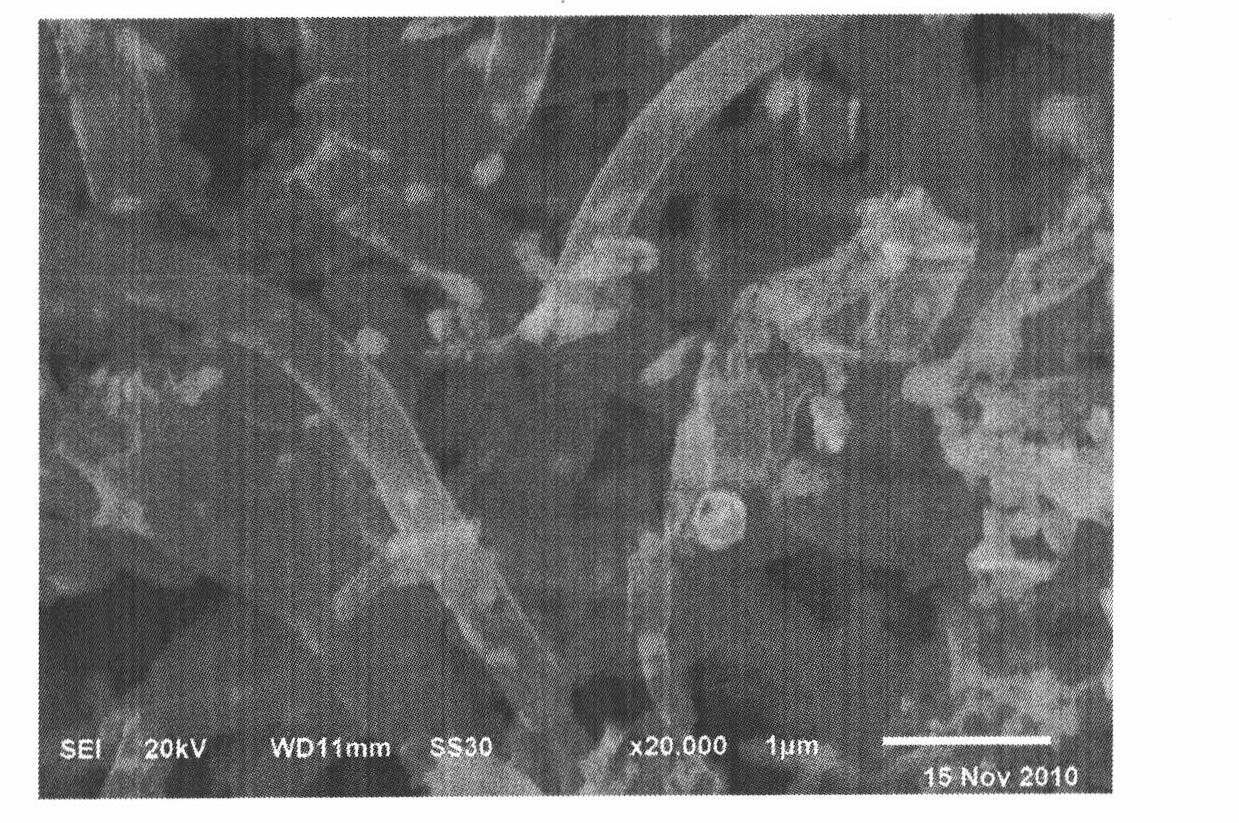

[0036] d) Dry the precursor nanofibers in a drying oven at 80°C for 10 hours, calcinate in an air atmosphere at 250°C for 4 hours, and then calcinate in an argon atmosphere at 800°C for 4 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com