Method for preparing magnetic iron oxide nano particles

A magnetic iron oxide, nanoparticle technology, applied in the fields of nanoscience, biological materials, and material chemistry, can solve the problems of poor crystallinity, uneven dispersion, affecting the application effect, etc., and achieve the effect of low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

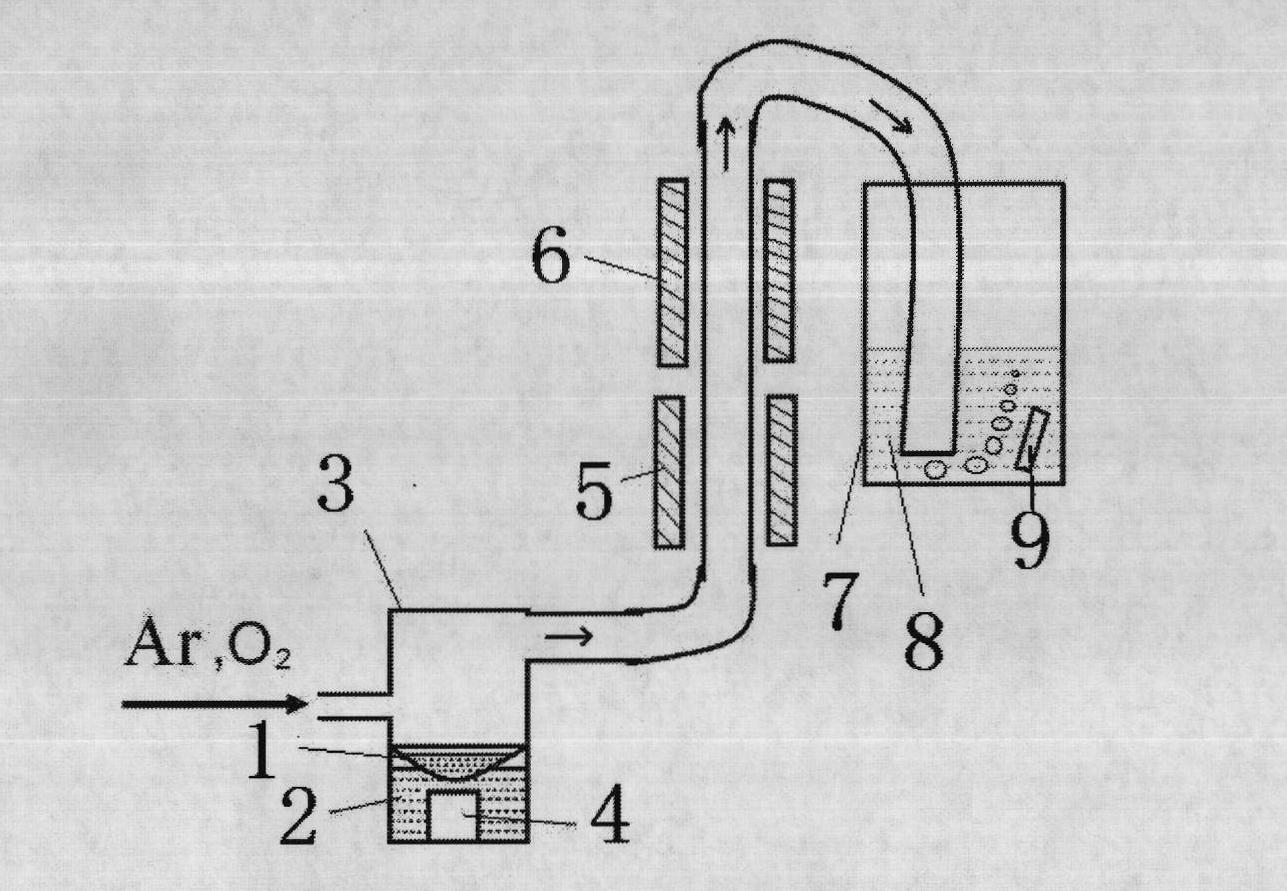

Method used

Image

Examples

Embodiment 1

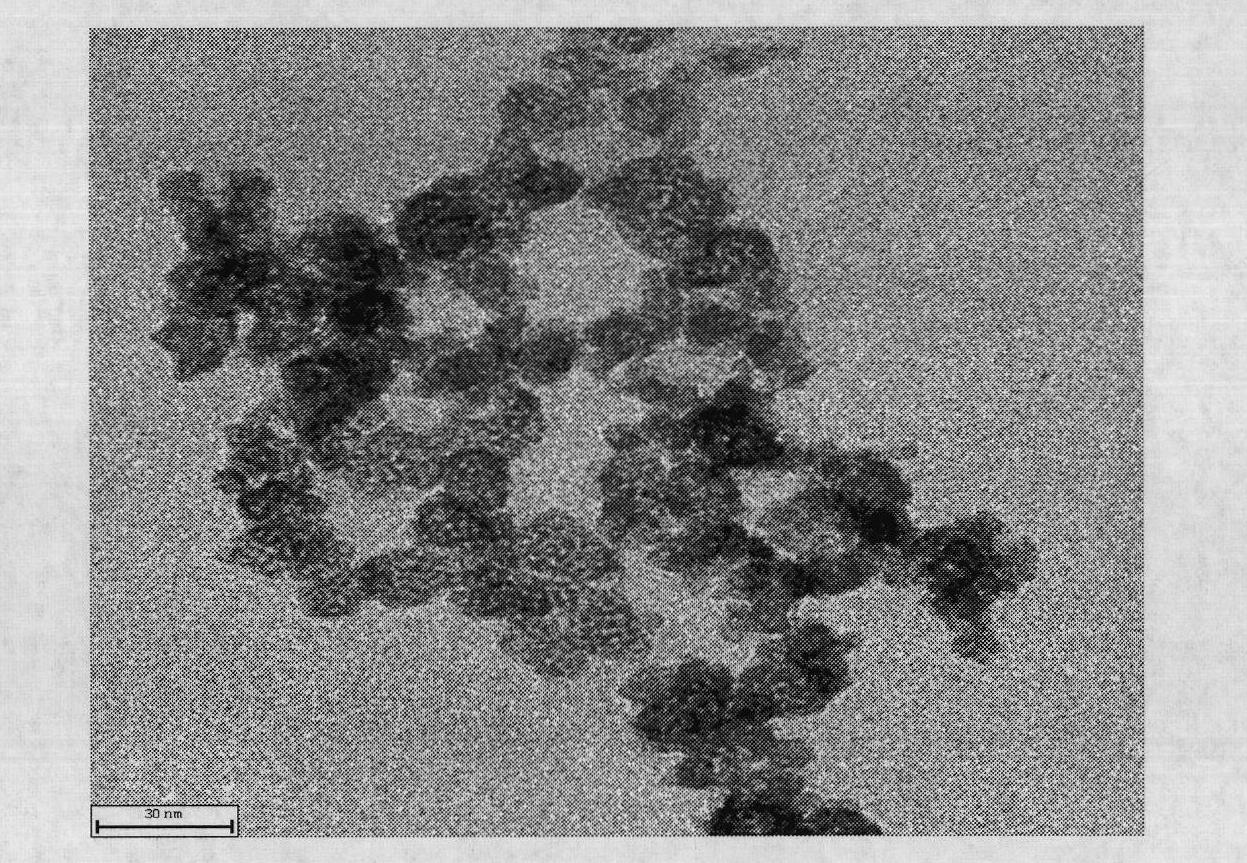

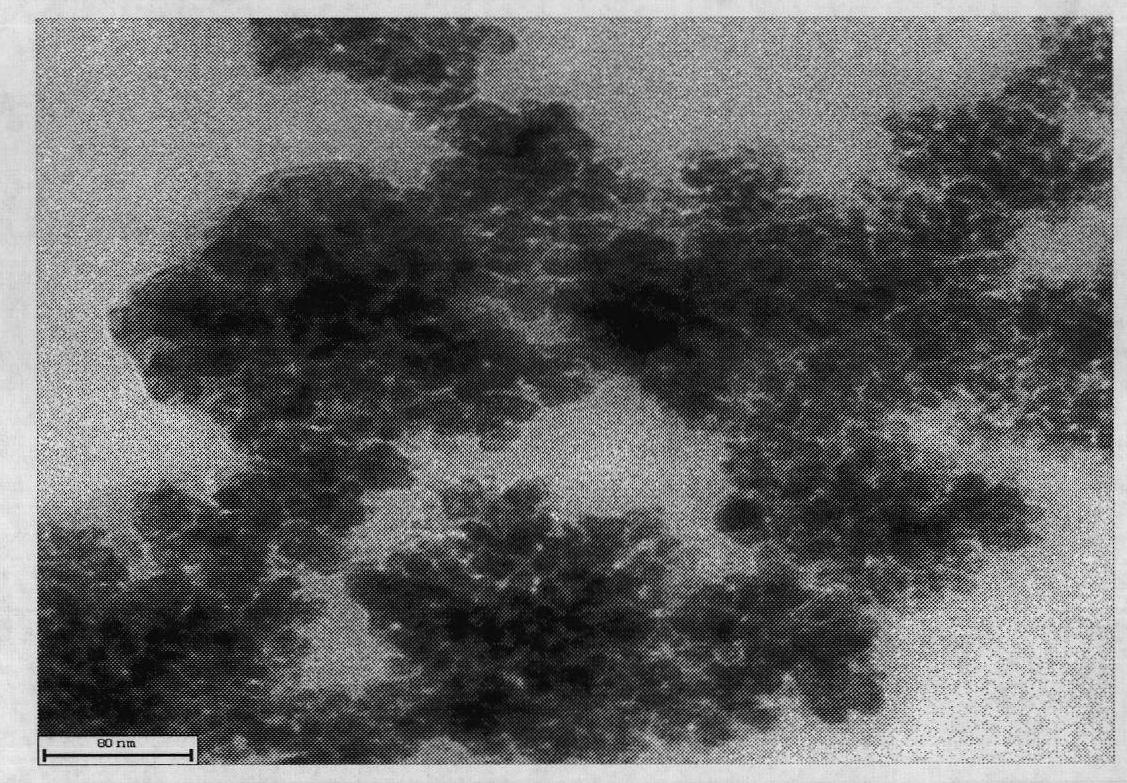

[0029] 0.08 g iron pentacarbonyl Fe(CO) 5 Dissolve it in 15ml of pure ethanol, pour the above solution into the atomization cup of the atomizer, and pass through the mixed gas of 600ml / min of argon and 3-4ml / min of oxygen. The two gases are mixed with a simple gas mixer. Ventilate for 10 minutes to remove the air in the system, and then start atomization, and the mixed gas of argon and oxygen loads the atomized liquid droplets into the heater. The temperature of the first heater (pre-heater) is 330°C, and the length of the constant temperature zone of the first heater is about 10cm; the temperature of the second heater (main heater) is 360°C, and the length of the constant temperature zone of the second heater is about 40cm; After iron pentacarbonyl is vaporized-decomposed-oxidized in the heater, the carrier gas is loaded into the collection solution, and the collection solution is composed of 20ml single-terminal carboxyl polyethylene glycol monomethyl ether (molecular weigh...

Embodiment 2

[0031] 0.85 g iron pentacarbonyl Fe(CO) 5 Dissolve it in 15ml of pure ethanol, pour the above solution into the atomization cup of the atomizer, and pass through the mixed gas of 300ml / min of argon and 3-4ml / min of oxygen. Operate in the same manner as in Example 1, the temperature of the first-stage heater is 230°C, and the temperature of the second-stage heater is 340°C. The vaporization-decomposition-oxidation product of iron pentacarbonyl is loaded into the collection liquid by the carrier gas, and the collection liquid is a mixed solution of 30ml single-terminal carboxyl polyethylene glycol (molecular weight: 1000), 30ml pure ethanol and 4ml oleylamine. The reaction and collection were carried out for 50 minutes. The product is brownish red. The treatment method is the same as in Example 1, that is, the product is added with pure ethanol, mixed evenly by ultrasonic waves, and the precipitate is dissolved in deionized water or pure ethanol after centrifugal cleaning. i...

Embodiment 3

[0033] 0.06 g iron pentacarbonyl Fe(CO) 5 Dissolve in 15ml of pure ethanol, then add 3 grams of triethylene glycol, pour the above solution into the atomization cup of the nebulizer, pass through the mixture of 600 ml / min of argon and 3-4 ml / min of oxygen gas. Operate in the same manner as in Example 1, the temperature of the first-stage heater is 330°C, and the temperature of the second-stage heater is 360°C. The vaporization-decomposition-oxidation product of iron pentacarbonyl is loaded into the collection liquid by the carrier gas, and the collection liquid is composed of 20ml single-terminal carboxyl polyethylene glycol monomethyl ether (molecular weight is 1200) dissolved in 50ml pure ethanol, and the collection The liquid container was cooled in an ice-water bath, and the collected liquid was stirred rapidly with a magnetic stirrer. The reaction and collection were carried out for 30 minutes. The product is brown-red translucent. In the same treatment as in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com