Method for preparing aluminium alloy-loaded titanium dioxide nano tube film

A technology of aluminum alloy surface and titanium dioxide, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor bonding force and unsuitability for large-scale application of aluminum alloys, and achieve good wear resistance, Excellent photocatalytic bactericidal performance, excellent photocatalytic antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

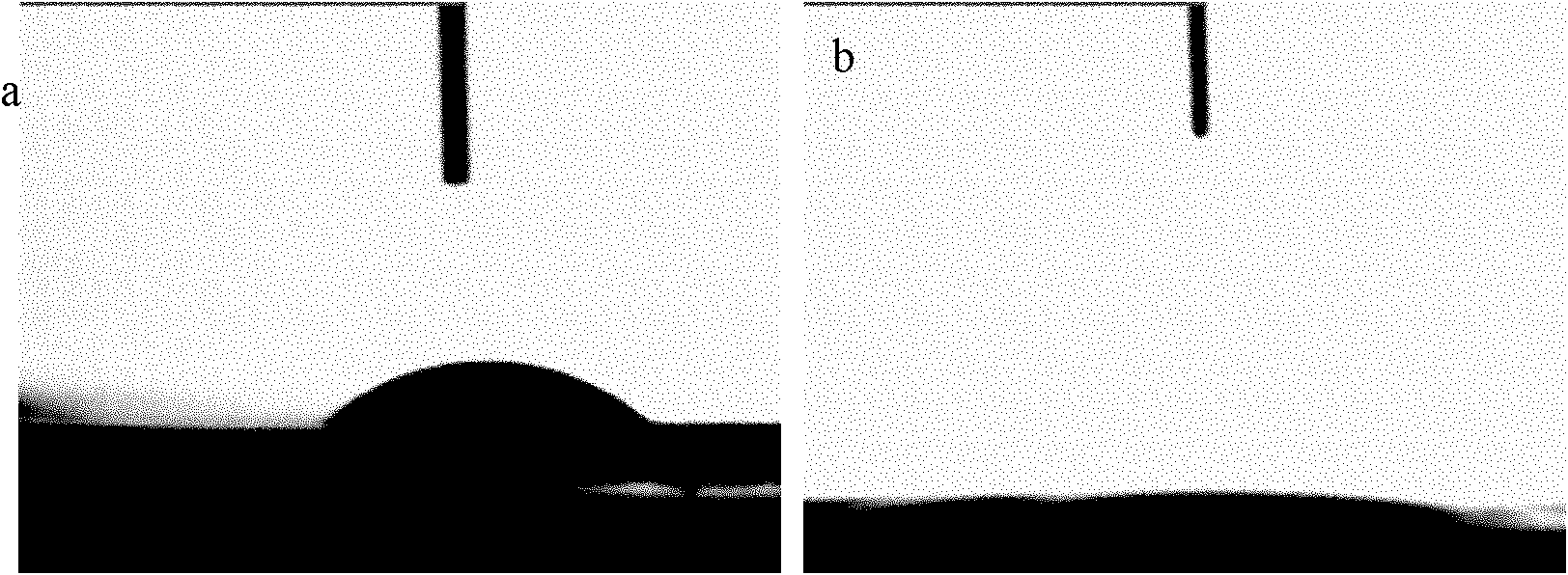

Image

Examples

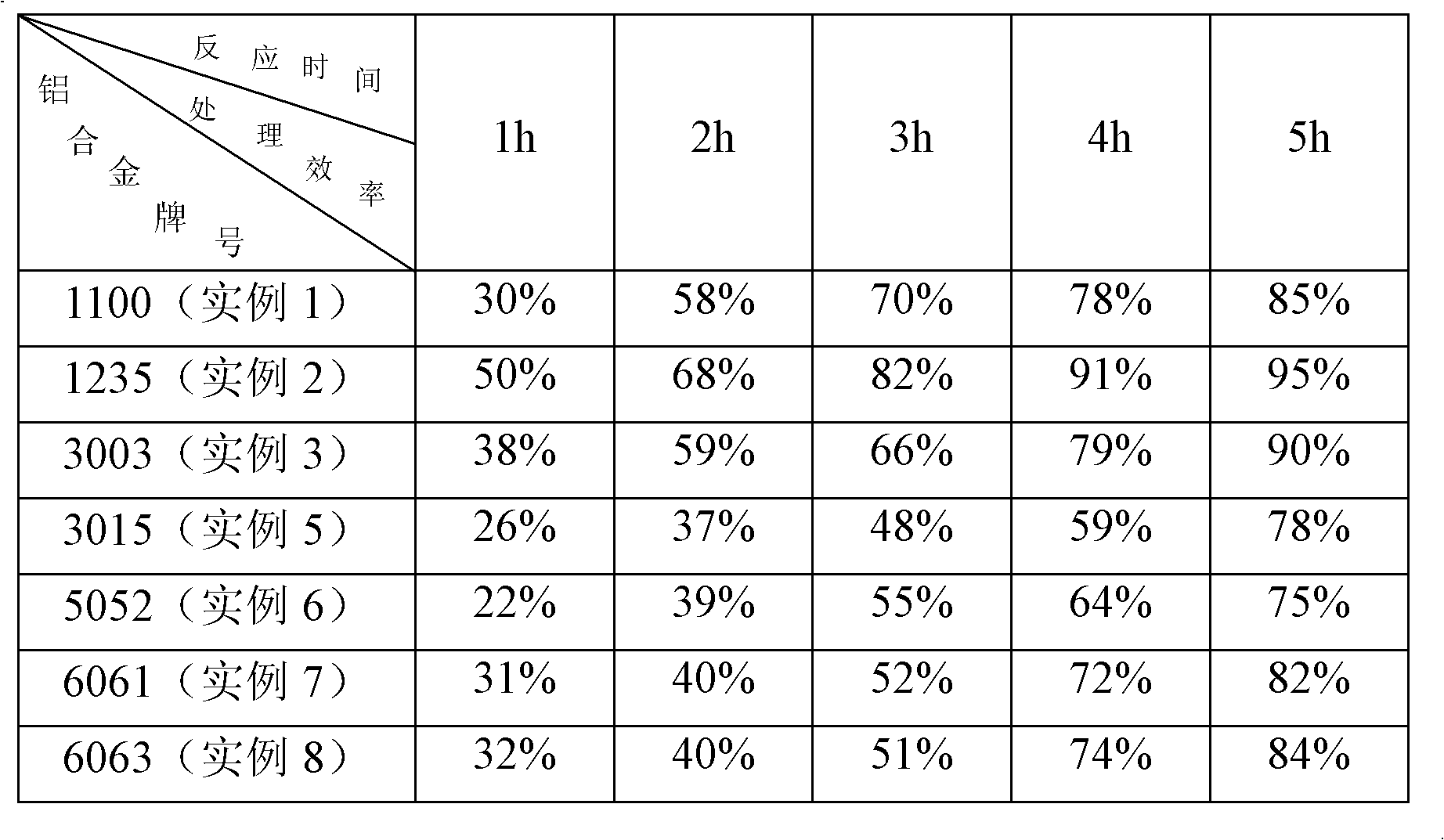

Embodiment 1

[0019] A solution of perchloric acid and ethanol with a volume ratio of 1:2 was used to electrochemically polish 1100 aluminum alloy samples at a voltage of 5V for 0.5min. The aluminum alloy is anodized with a concentration of 0.1M H 3 PO 4 It is an electrolyte solution, the oxidation voltage is 20V, the temperature is 30°C, and the oxidation time is 4h. The aluminum substrate on which the anodized aluminum nanotube array template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water for use. Prepare 0.5M (NH 4 ) 2 TiF 6 The liquid phase deposition solution was fully stirred and placed in a water bath at 30°C for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 After being deposited in the solution for 15 minutes, it was taken out, washed with deionized water and dried. Then heat up at 400°C for 3 hours and cool to room temperature with the furnace. Table 2 shows the values of titanium dioxide nanotube films on aluminum alloy...

Embodiment 2

[0021] The 1235 aluminum alloy sample was electrochemically polished with a solution of perchloric acid and ethanol at a volume ratio of 1:2 at a voltage of 10V for 1 min. Anodizing the aluminum alloy, using H at a concentration of 0.2M 3 PO 4 It is an electrolytic solution, the oxidation voltage is 40V, the temperature is 20°C, and the oxidation time is 6h. The aluminum substrate on which the anodized aluminum nanotube array template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water for use. Prepare 0.1M (NH 4 ) 2 TiF 6 The liquid phase deposition solution was fully stirred and placed in a water bath at 35°C for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 After being stirred and deposited in the solution for 20 minutes, it was taken out, washed with deionized water and dried. Then heat up at 500°C for 2 hours and cool to room temperature with the furnace. Table 2 shows the values of titanium dioxide nanotube films o...

Embodiment 3

[0023] The 3003 aluminum alloy sample was electrochemically polished with a solution of perchloric acid and ethanol at a volume ratio of 1:3 at a voltage of 10V for 1 min. Anodizing the aluminum alloy with a concentration of 1M H 3 PO 4 It is an electrolytic solution, the oxidation voltage is 60V, the temperature is 20°C, and the oxidation time is 10h. The aluminum substrate on which the anodized aluminum nanotube array template (AAO) has been grown after anodic oxidation is taken out and cleaned with deionized water for use. Prepare 0.05M (NH 4 ) 2 TiF 6 The liquid phase deposition solution was fully stirred and placed in a water bath at 40°C for later use. Dip the AAO template into (NH 4 ) 2 TiF 6 After being stirred and deposited in the solution for 30 minutes, it was taken out, washed with deionized water and dried. Then heat up at 500°C for 3 hours and cool to room temperature with the furnace. The energy spectrum (EDS) elemental analysis of the titanium dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com