Preparation process of magnesium alloy supported nanometer TiO2 photocatalyst film

A technology of photocatalytic thin film and magnesium alloy, which is applied in the direction of titanium dioxide, liquid chemical plating, metal material coating technology, etc., can solve the problems of poor corrosion resistance of magnesium and magnesium alloy, reduce the composite probability, improve the application range, The effect of excellent photocatalytic sterilization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

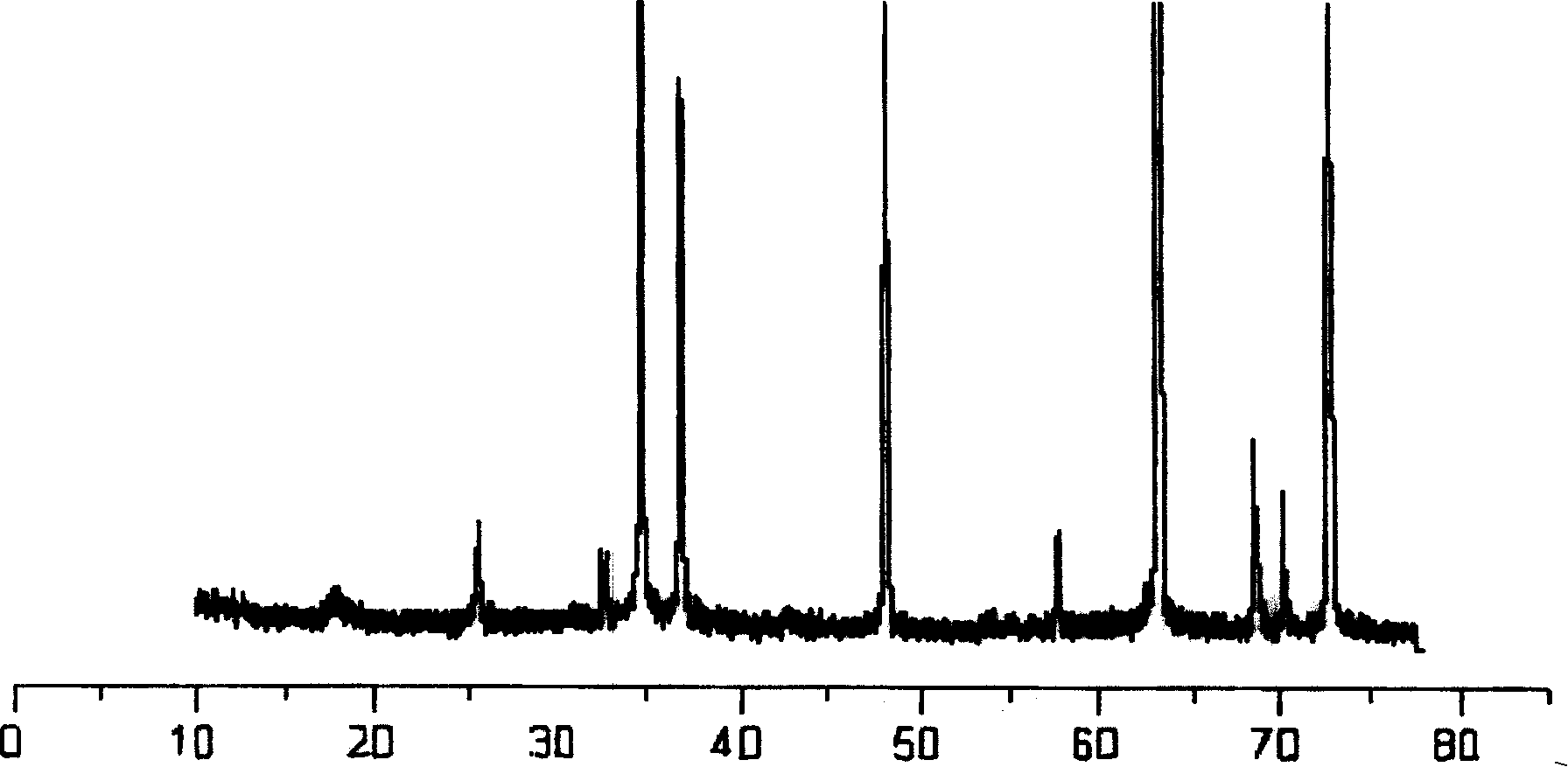

Image

Examples

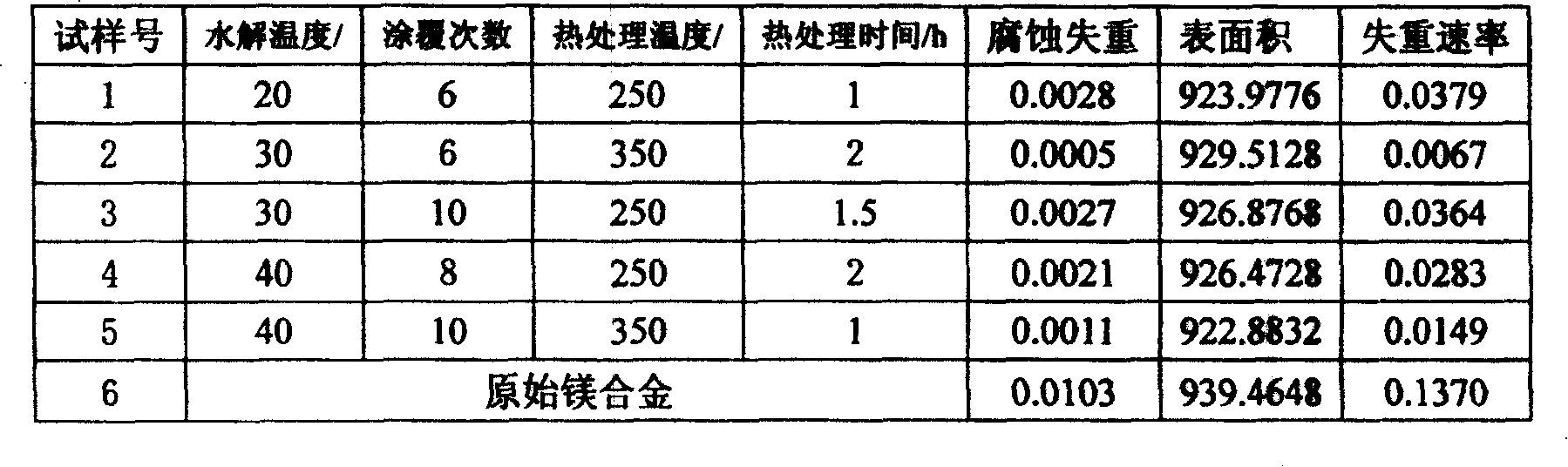

Embodiment 1

[0029] Magnesium alloy loaded nano TiO of the present invention 2 The raw materials used in the preparation method of the photocatalytic thin film are: absolute ethanol (analytical pure AR grade), tetrabutyl titanate (analytical pure AR grade), diethanolamine (analytical pure AR grade), deionized water, methylene blue (analytical pure AR grade). Pure AR grade), magnesium alloy. Its preparation method is as follows: (1) preparation of sol; the volume ratio of each raw material is as follows, tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine = 15:74:11:8; first add the above volume to the beaker under the condition of stirring, add tetrabutyl titanate and continue stirring for 1 hour; add diethanolamine and continue stirring for 20 minutes; then add deionized water dropwise and continue stirring for 20 minutes; according to the amount of 1 gram per 500ml of sol Add TiO 2 Nano-powder, pH is 6.5, ultrasonically dispersed for 0.5 hours, and aged for 20 hours;...

Embodiment 2

[0031] Magnesium alloy loaded nano TiO of the present invention 2 The raw materials used in the preparation method of the photocatalytic thin film are: absolute ethanol (analytical pure AR grade), tetrabutyl titanate (analytical pure AR grade), diethanolamine (analytical pure AR grade), deionized water, methylene blue (analytical pure AR grade). Pure AR grade), magnesium alloy. The specific preparation method is as follows: (1) prepare sol; the volume ratio of each raw material is as follows, tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine=4:90:6:5; first add the above-mentioned volume in the beaker Absolute ethanol; in the case of stirring, add tetrabutyl titanate and continue stirring for 1 hour; add diethanolamine and continue stirring for half an hour; then add deionized water dropwise and continue stirring for half an hour; Amount of TiO added 2Nano-powder, ultrasonically dispersed for 1 hour, aged for 40 hours; (2) pre-preparation treatment a, th...

Embodiment 3

[0033] Magnesium alloy loaded nano TiO of the present invention 2 The raw materials used in the preparation method of the photocatalytic thin film are: absolute ethanol (analytical pure AR grade), tetrabutyl titanate (analytical pure AR grade), diethanolamine (analytical pure AR grade), deionized water, methylene blue (analytical pure AR grade). Pure AR grade), magnesium alloy. The specific preparation method is as follows: (1) preparation of sol; the volume ratio of each raw material is as follows, tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine=21:77:2:1; first add the above-mentioned volume in the beaker Absolute ethanol; in the case of stirring, add tetrabutyl titanate and continue stirring for 1 hour; add diethanolamine and continue stirring for half an hour; then add deionized water dropwise and continue stirring for half an hour; Amount of TiO added 2 Nano-powder, ultrasonically dispersed for 1 hour, aged for 60 hours; (2) pre-preparation treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com