Noble metal-carrying titanium dioxide catalyst and preparation method and use thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., to achieve good selectivity, recovery of catalytic activity, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

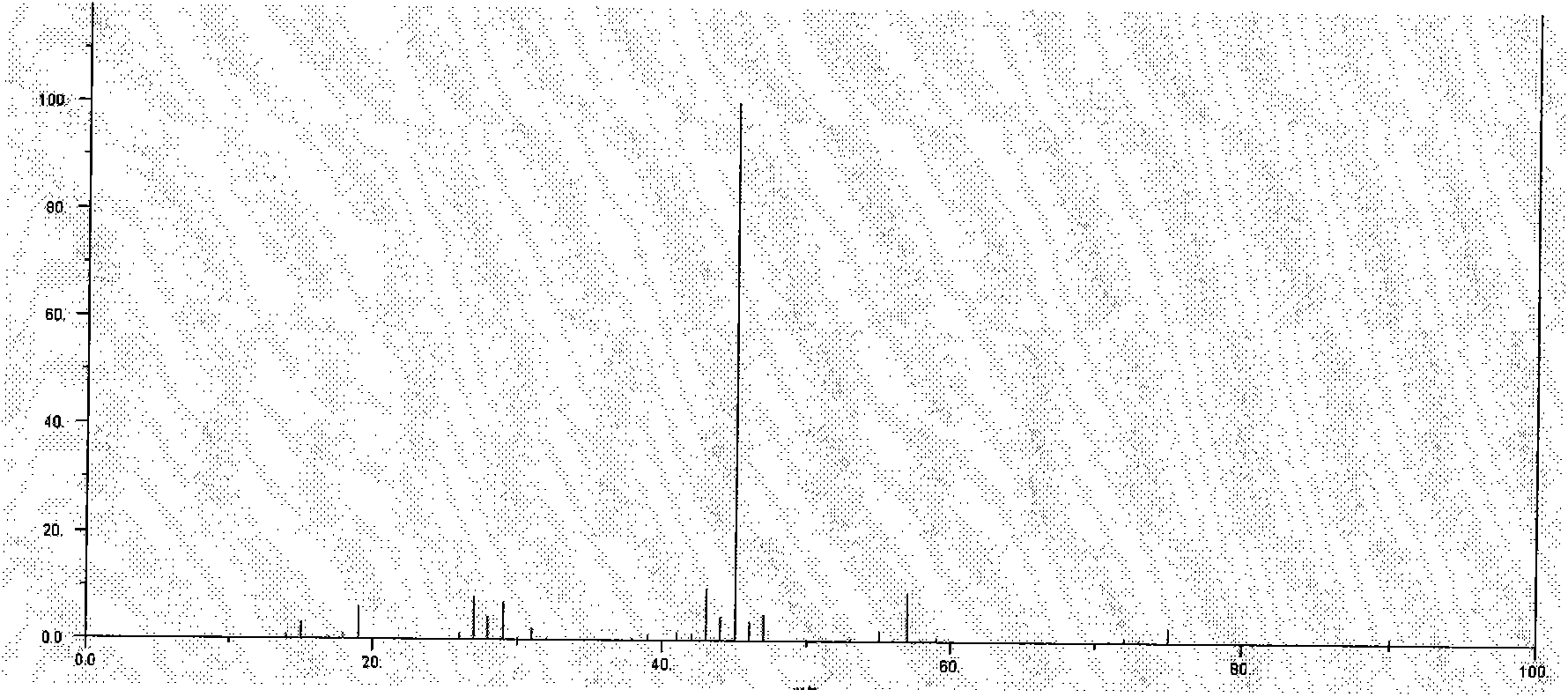

Embodiment 1

[0027] Commercial Degussa P25 nano-titanium dioxide was calcined at 900°C for 8 hours to obtain pure rutile nano-titanium dioxide. Get 1 gram of pure rutile nano-titanium dioxide and disperse it in 200mL of 10% (v / v) ethanol aqueous solution, add chloroplatinic acid (1g / 10ml) as 1%wt% by load, vacuumize under magnetic stirring, to remove After the air in the system is removed, turn on the 500W ultraviolet lamp to irradiate, so that the platinum ions are photocatalytically reduced to nano-metal platinum particles in situ, and at the same time, the photocatalytic ethanol selective oxidation reaction is carried out, and the reaction time is 120h. The liquid phase product detected by chromatography is mainly 2,3-butanediol with a selectivity of 96.6% and an ethanol conversion rate of 28%.

Embodiment 2

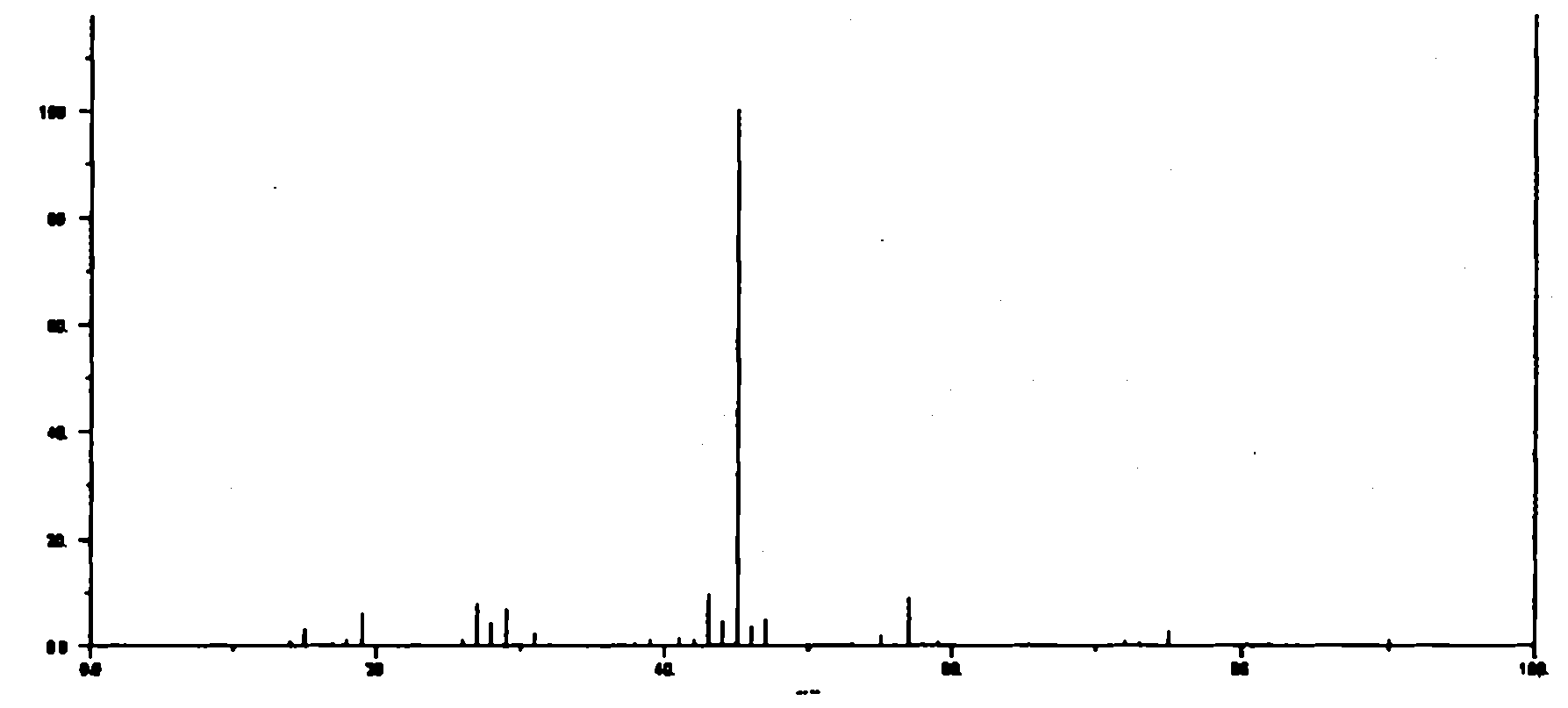

[0029] Homemade TiO 2 Dry sol (dissolve 50mL of tetrabutyl titanate in 126mL of absolute ethanol, add 3g of acetylacetone as a stabilizer, stir magnetically for 12 hours, age for 3 days, dry at 60°C for 7 days to become a dry sol), grind for 600 °C for 5 hours to obtain nanometer titanium dioxide with a ratio of anatase type and rutile type of 50:50. Take 1g of anatase-type and rutile-type ratio and disperse it into 400mL of 99% (v / v) ethanol aqueous solution, and add palladium chloride according to the loading capacity of 4%wt%, and vacuumize under magnetic stirring , to remove the air in the system, turn on the 300W ultraviolet lamp to irradiate, so that the palladium ions are photocatalytically reduced to nano-metal palladium particles in situ, and then the photocatalytic ethanol selective oxidation reaction is carried out. The reaction time is 20h. The liquid phase product detected by chromatography is mainly 2,3-butanediol, the selectivity is 90.6%, and the conversion r...

Embodiment 3

[0031] Homemade TiO 2 Dry sol (dissolve 70mL of tetrabutyl titanate in 250mL of absolute ethanol, add 4g of acetylacetone as a stabilizer, stir magnetically for 18 hours, age for 4 days, dry at 70°C for 10 days to become a dry sol), grind for 500 °C for 1 hour to obtain pure anatase nano-titanium dioxide. Take 1g of pure anatase-type nano-titanium dioxide and disperse it in 200mL of 30% (v / v) ethanol aqueous solution, add silver nitrate to make the load reach 0.5%, and feed nitrogen gas under magnetic stirring to remove the air in the system Afterwards, 2000W ultraviolet lamp is irradiated to make the silver ions photocatalytically reduce into nano-metallic silver particles in situ, and then carry out the photocatalytic ethanol selective oxidation reaction, and the reaction time is 10h. The selectivity of 2,3-butanediol in the liquid phase product detected by chromatography is 15.3%, and the conversion rate of ethanol is 7.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com