Single-component epoxy structure adhesive tape and preparation method thereof

A single-component, epoxy technology, applied in the direction of epoxy resin glue, adhesives, non-polymer adhesive additives, etc., can solve the problems of easy air bubbles, waste of glue, etc., to avoid glue leakage and bonding The effect of high strength, easy use and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

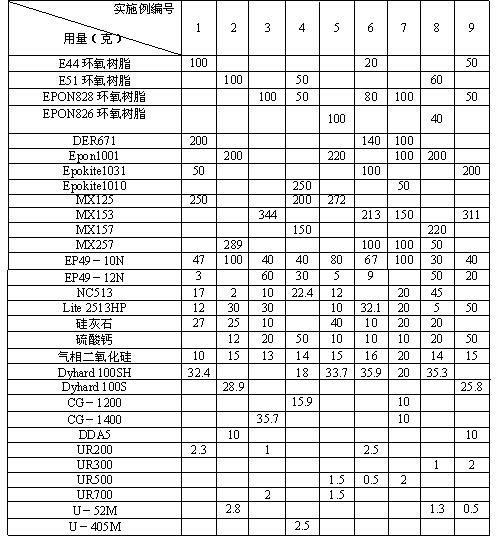

[0033] Further illustrate the present invention with embodiment below, but the present invention is not limited thereto;

[0034] Preparation of one-component aging-resistant epoxy resin adhesive composition:

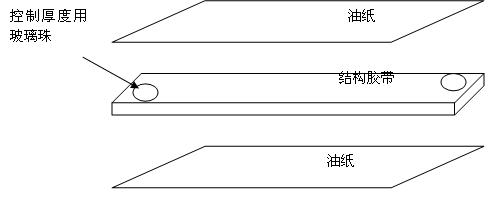

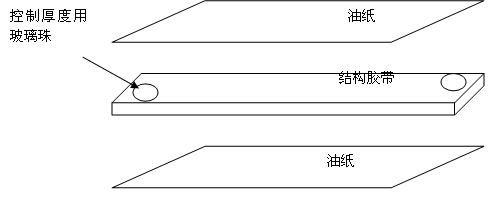

[0035] Mix and stir the solid bisphenol A epoxy resin, liquid bisphenol A epoxy resin and epoxy diluent at 90-100°C according to the weight ratio for 20 minutes, maintain the atmospheric pressure at 0.1 atmosphere, then cool to 60°C, add Mix toughness modified epoxy resin and phosphating modified epoxy resin for 10 minutes, keep the air pressure at 0.1 atmosphere, then add thixotropic agent and filler, mix and stir for 15 minutes, keep the air pressure at 0.1 atmosphere, cool to 50°C Add a dicyandiamide curing agent and a urea curing accelerator, mix and stir for 15 minutes, and then discharge the material, maintaining an atmospheric pressure of 0.1 to 0.2 atmospheric pressure; place the obtained paste between two pieces of oil paper, and press it on a flat press until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com