Method for preparing graphite anode material of membrane-structural lithium ion battery by hot coating method

A lithium-ion battery, graphite anode technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of equipment maintenance, complex process, complex process, uneven thickness of the coating layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

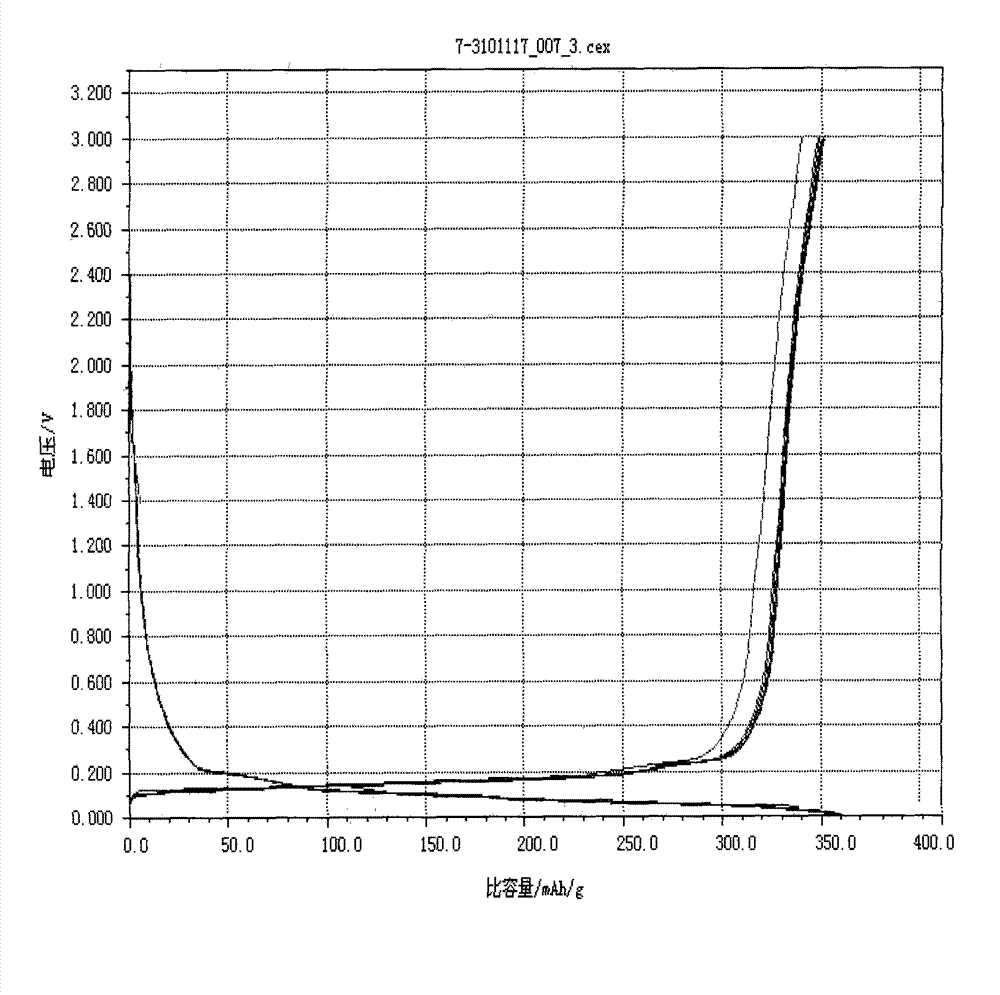

Embodiment 1

[0036] Weigh 100g of spherical natural graphite 1 with a particle size D50 of 18 μm and add it into the stirring tank 4 with a double-helix heating jacket, then weigh petroleum pitch micropowder 2 and anthracene oil 3 respectively as 15 g and 30 g and add it into the stirring tank 4, and turn on the stirring tank 4. Double-helix stirring, stirring for 2 hours, turning on the heating device of the stirring tank 4, raising the temperature to 250°C at a heating rate of 100°C per hour, continuing to stir for 2 hours, then putting the obtained material into a 95% corundum crucible, and then placing it in a In the atmosphere-protected heating furnace, adjust the heating speed of the heating furnace to raise the temperature from 50°C to 350°C per hour and keep the temperature for 3 hours, continue to raise the temperature to 800°C and keep it for 2 hours, then raise the temperature to 1200°C and keep it for 4 hours, and then cool to room temperature. The material is taken out and siev...

Embodiment 2

[0038]Weigh 100g of flaky natural graphite 1 with a particle size D50 of 20 μm and add it to the stirring tank 4 with a double-helix heating jacket, then weigh petroleum pitch micropowder 2 and coal tar 3 to 18g and 20g respectively, add them to the stirring tank 4, and turn on the stirring tank 4 The double-helix stirring, stirring for 2 hours, turned on the heating device of the stirring tank 4, and raised the temperature to 280°C at a heating rate of 150°C per hour, and continued to stir for 3 hours. In the heating furnace with atmosphere protection, adjust the heating speed of the heating furnace to raise the temperature from 50°C to 350°C per hour and keep the temperature for 2 hours, continue to raise the temperature to 800°C and keep it for 2 hours, then raise the temperature to 1200°C and keep it for 4 hours, then cool to room temperature , the material is taken out and sieved into fine powder and impurities are removed, and the thermal coating of the surface-coated car...

Embodiment 3

[0040] Weigh 100g of spherical natural graphite 1 with a particle size D50 of 18 μm and add it into the stirring tank 4 with a double-helix heating jacket, then weigh the coal tar pitch micropowder 2 and anthracene oil 3 as 15 g and 50 g and add it into the stirring tank 4, and turn on the stirring tank 4. Double-helix stirring, stirring for 2 hours, turning on the heating device of the stirring tank 4, raising the temperature to 250°C at a heating rate of 100°C per hour, continuing to stir for 2 hours, then putting the obtained material into a 95% corundum crucible, and then placing it in a In the atmosphere-protected heating furnace, adjust the heating speed of the heating furnace to raise the temperature from 50°C to 300°C per hour, keep the temperature for 2 hours, continue to heat up to 800°C and keep it for 2 hours, then raise the temperature to 1200°C and keep it for 4 hours, and continue to heat up to 2800°C Insulate for 18 hours, then cool to room temperature, take out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com