Ternary copolymerization highly hydrophilic polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

A polyacrylonitrile-based carbon fiber and spinning solution technology, which is applied in the direction of spinning solution preparation, fiber chemical characteristics, single-component synthetic polymer rayon, etc. Problems such as poor water resistance, to reduce surface tension and contact angle, improve uniformity and compactness, and avoid severe heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

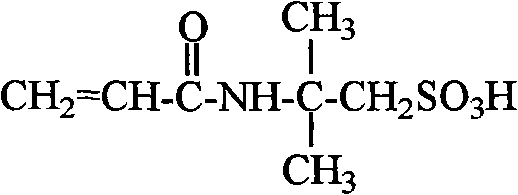

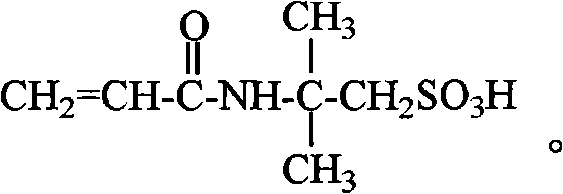

[0020] Add the main monomer (acrylonitrile) / comonomer 1 (itaconic acid) / comonomer 2 (AMPS) into the reactor according to the ratio of 99.50 / 0.45 / 0.05, and the mass concentration of the total monomer is 10%. The amount of nitrogen bisisobutyronitrile is 0.3% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 10 minutes to replace the air in the reaction system, start stirring and raise the temperature to 50°C, and polymerize for 15 hours under the protection of nitrogen to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution. The contact angle of PAN resin is 54.5°, and the surface tension is 38.9dyn / cm.

Embodiment 2

[0022] The main monomer (acrylonitrile) / comonomer 1 (itaconic anhydride) / comonomer 2 (AMPS) is added in the reactor according to the ratio of 96.90 / 2.00 / 0.10, and the mass concentration of the total monomer is 12%. The amount of nitrogen bisisobutyronitrile is 0.5% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 20 minutes to replace the air in the reaction system, start stirring and raise the temperature to 60°C, and polymerize for 20 hours under the protection of nitrogen to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution. The contact angle of PAN resin is 54.1°, and the surface tension is 37.1dyn / cm.

Embodiment 3

[0024] The main monomer (acrylonitrile) / comonomer 1 (itaconic acid) / comonomer 2 (AMPS) is added in the reactor according to the ratio of 98.88 / 2.00 / 0.12, and the mass concentration of the total monomer is 14%. The amount of nitrogen bisisobutyronitrile is 0.7% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 25 minutes to replace the air in the reaction system, start stirring and raise the temperature to 60°C, and polymerize under the protection of nitrogen for 18 hours to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution . The contact angle of PAN resin is 53.9°, and the surface tension is 36.3dyn / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com