Ternary copolymerization highly hydrophilic polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

A technology of polyacrylonitrile-based carbon fiber and spinning solution, which is applied in the field of ternary copolymerization of high-hydrophilic polyacrylonitrile-based carbon fiber spinning solution and preparation, can solve the problem of large difference in polymerization rate, high preparation cost and hydrophilicity. It can reduce the surface tension and contact angle, improve the uniformity and density, and avoid severe heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

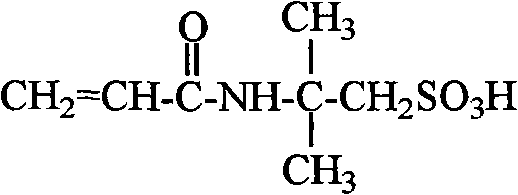

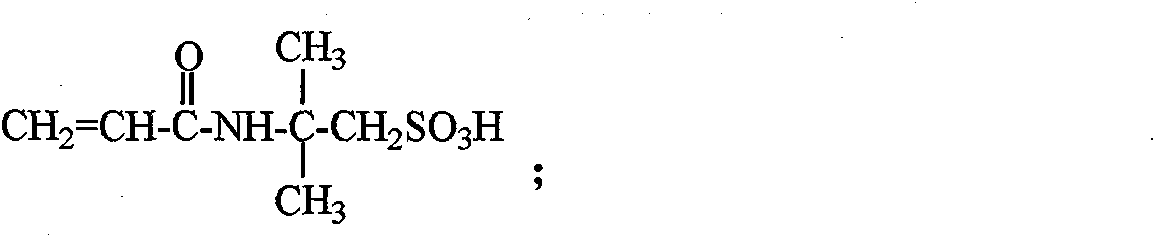

Image

Examples

Embodiment 1

[0020] Add the main monomer (acrylonitrile) / comonomer 1 (itaconic acid) / comonomer 2 (AMPS) into the reactor according to the ratio of 99.50 / 0.45 / 0.05, and the mass concentration of the total monomer is 10%. The amount of nitrogen bisisobutyronitrile is 0.3% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 10 minutes to replace the air in the reaction system, start stirring and raise the temperature to 50°C, and polymerize for 15 hours under the protection of nitrogen to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution. The contact angle of PAN resin is 54.5°, and the surface tension is 38.9dyn / cm.

Embodiment 2

[0022] The main monomer (acrylonitrile) / comonomer 1 (itaconic anhydride) / comonomer 2 (AMPS) is added in the reactor according to the ratio of 96.90 / 2.00 / 0.10, and the mass concentration of the total monomer is 12%. The amount of nitrogen bisisobutyronitrile is 0.5% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 20 minutes to replace the air in the reaction system, start stirring and raise the temperature to 60°C, and polymerize for 20 hours under the protection of nitrogen to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution. The contact angle of PAN resin is 54.1°, and the surface tension is 37.1dyn / cm.

Embodiment 3

[0024] The main monomer (acrylonitrile) / comonomer 1 (itaconic acid) / comonomer 2 (AMPS) is added in the reactor according to the ratio of 98.88 / 2.00 / 0.12, and the mass concentration of the total monomer is 14%. The amount of nitrogen bisisobutyronitrile is 0.7% of the total weight of monomers, and dimethyl sulfoxide is used as a solvent for copolymerization. Introduce high-purity nitrogen into the reactor for 25 minutes to replace the air in the reaction system, start stirring and raise the temperature to 60°C, and polymerize under the protection of nitrogen for 18 hours to obtain a ternary copolymerization highly hydrophilic acrylonitrile-based carbon fiber spinning solution . The contact angle of PAN resin is 53.9°, and the surface tension is 36.3dyn / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com