Photoelectric device including lithium titanate membrane electrode and application thereof

A thin-film electrode and optoelectronic device technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of slow response speed of color change of inorganic color-changing films, poor chemical stability of organic color-changing films, poor substrate adhesion, etc., and achieve excellent cycle stability Durability, high coloring and fading response speed, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. Preparation of a lithium titanate thin film electrode of the present invention as a color-changing electrode of an electrochromic device.

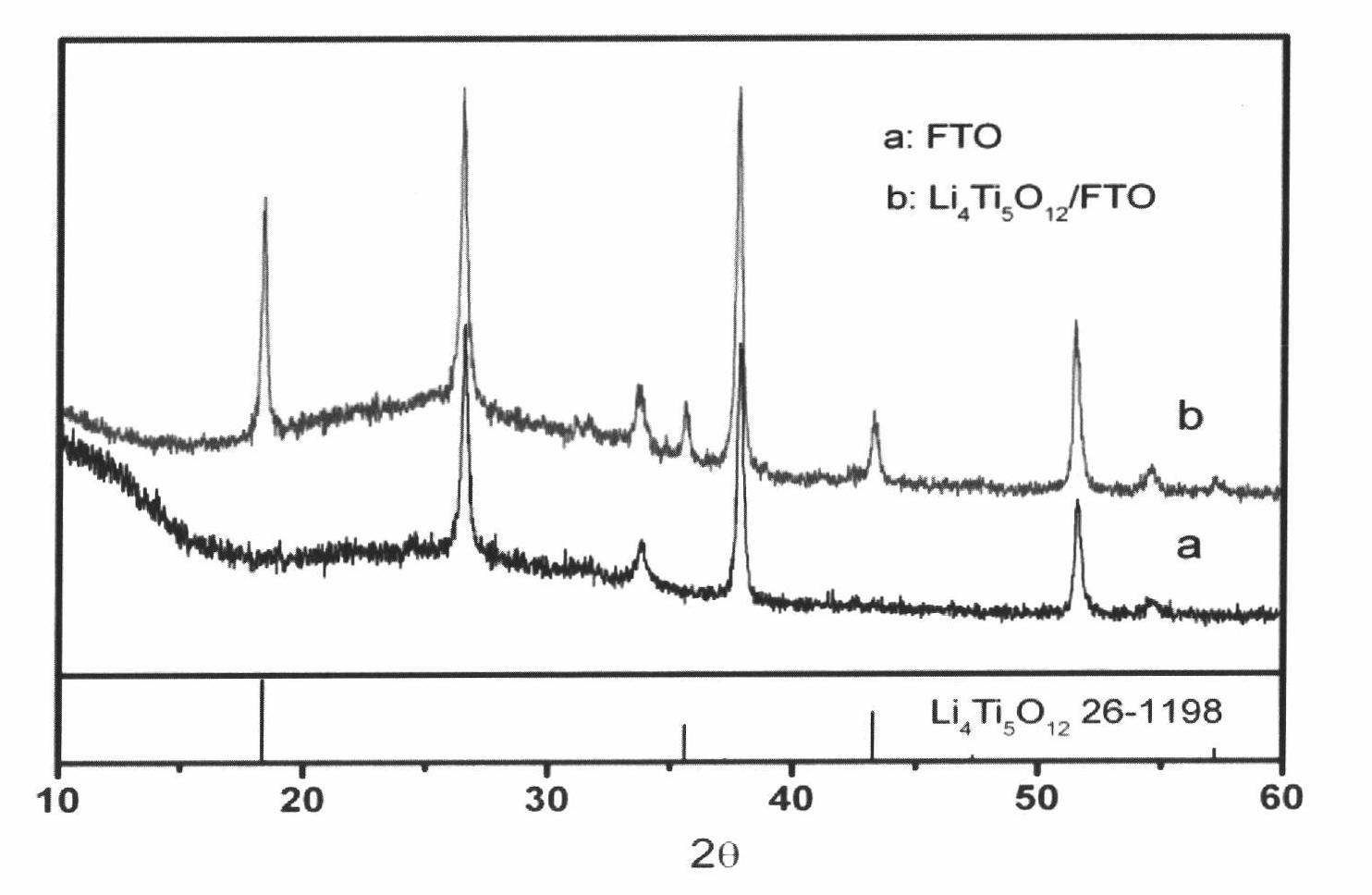

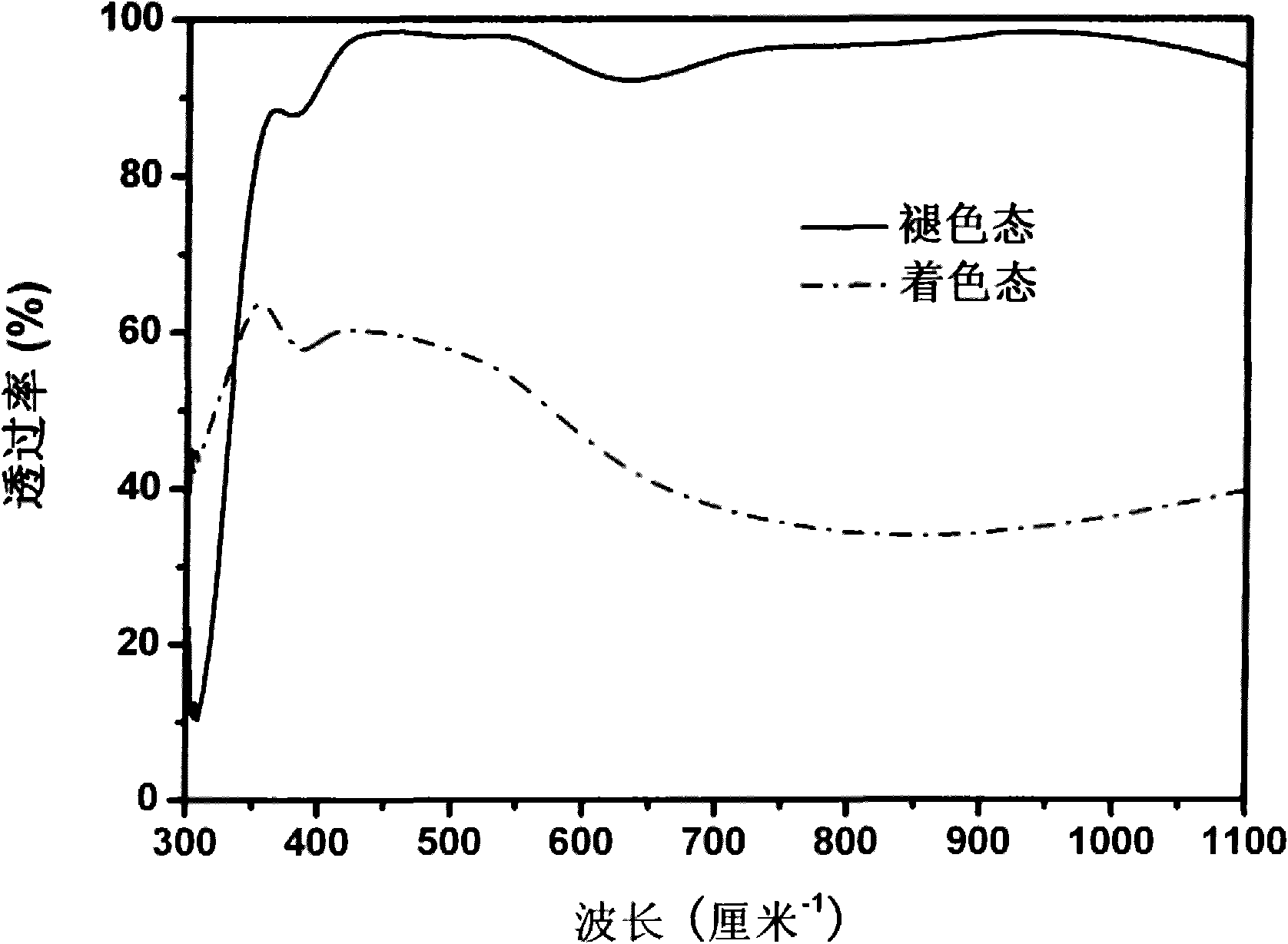

[0030] Lithium titanate thin film electrodes can be prepared by the following method. Using the radio frequency sputtering method, the phase-pure spinel-structured Li 4 Ti 5 o 12 The ceramic sheet is used as the target material, and the deposition atmosphere is Ar / O 2 Mixed gas (Ar and O 2 The flow ratio is 1:2), the deposition pressure is 1.0Pa, the radio frequency power is 200 watts, the deposition temperature is 600°C, and the deposition time is 1 hour, and the 500nm thick Li 4 Ti 5 o 12 film. The X-ray diffraction (XRD) spectrum of the film electrode is as follows figure 1 As shown, using the Li 4 Ti 5 o 12 The film is used as the color-changing electrode of the electrochromic device, using the metal Li ion storage layer as the counter electrode, 1mol LiCiO 4 Dissolve in 1L propylene carbonate (PC) solutio...

Embodiment 2

[0031] Example 2. Preparation of a photoelectric device containing a lithium titanate thin film electrode according to the present invention.

[0032] Photoelectric devices containing lithium titanate thin film electrodes can be prepared by the following method. Using pulsed laser sputtering method, 248 nm excimer laser as laser source, pure phase Li 4 Ti 5 o 12 The ceramic sheet was used as the target material, and the deposition atmosphere was O 2 , the deposition pressure was 20Pa, the deposition temperature was 500°C, and the deposition time was 2 hours, the 500nm thick Li was deposited on indium tin oxide (ITO) transparent conductive glass. 4 Ti 5 o 12 film. in Li 4 Ti 5 o 12 Deposit 1um LiLaTiO on the thin film 3 As the electrolyte material, then in LiLaTiO 3 Deposit 200nmLiFePO on 4 thin film as an ion storage layer, and finally in LiFePO 4 20nm Pt was deposited on the film as a current collector. That is to prepare a Li 4 Ti 5 o 12 The thin-film electr...

Embodiment 3

[0033] Example 3. Preparation of a photoelectric device containing a lithium titanate thin film electrode according to the present invention.

[0034] Photoelectric devices containing lithium titanate thin film electrodes can be prepared by the following method. 10g Li 4 Ti 5 o 12 and 2g nano-Al 2 o 3 Disperse in 50 mL of polymethyl methacrylate (PMMA) to form a slurry. This slurry was spin-coated on indium tin oxide (ITO) transparent conductive glass for 2 minutes at a spin-coating rate of 4000 rpm, and then heat-treated at 450°C in air for 30 minutes to prepare Li 4 Ti 5 o 12 Li as the matrix 4 Ti 5 o 12 and Al 2 o 3 Composite thin film electrodes. Use this thin film electrode as a color-changing electrode of an electrochromic device, using lithiated CeO deposited on indium tin oxide (ITO) transparent conductive glass 2 As the ion storage layer constitutes the counter electrode, the electrolyte is 1mol LiPF 6 Soluble in 1L of a mixed solvent of EC (ethylene ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com