Titanium alloy integral bladed disc and manufacturing method thereof

A technology of integral blades and manufacturing methods, which is applied to liquid fuel engines, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of difficult technical realization and low strength of the connection interface, and achieve Improve the utilization rate and structural efficiency, reduce the amount of processing, the effect of high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

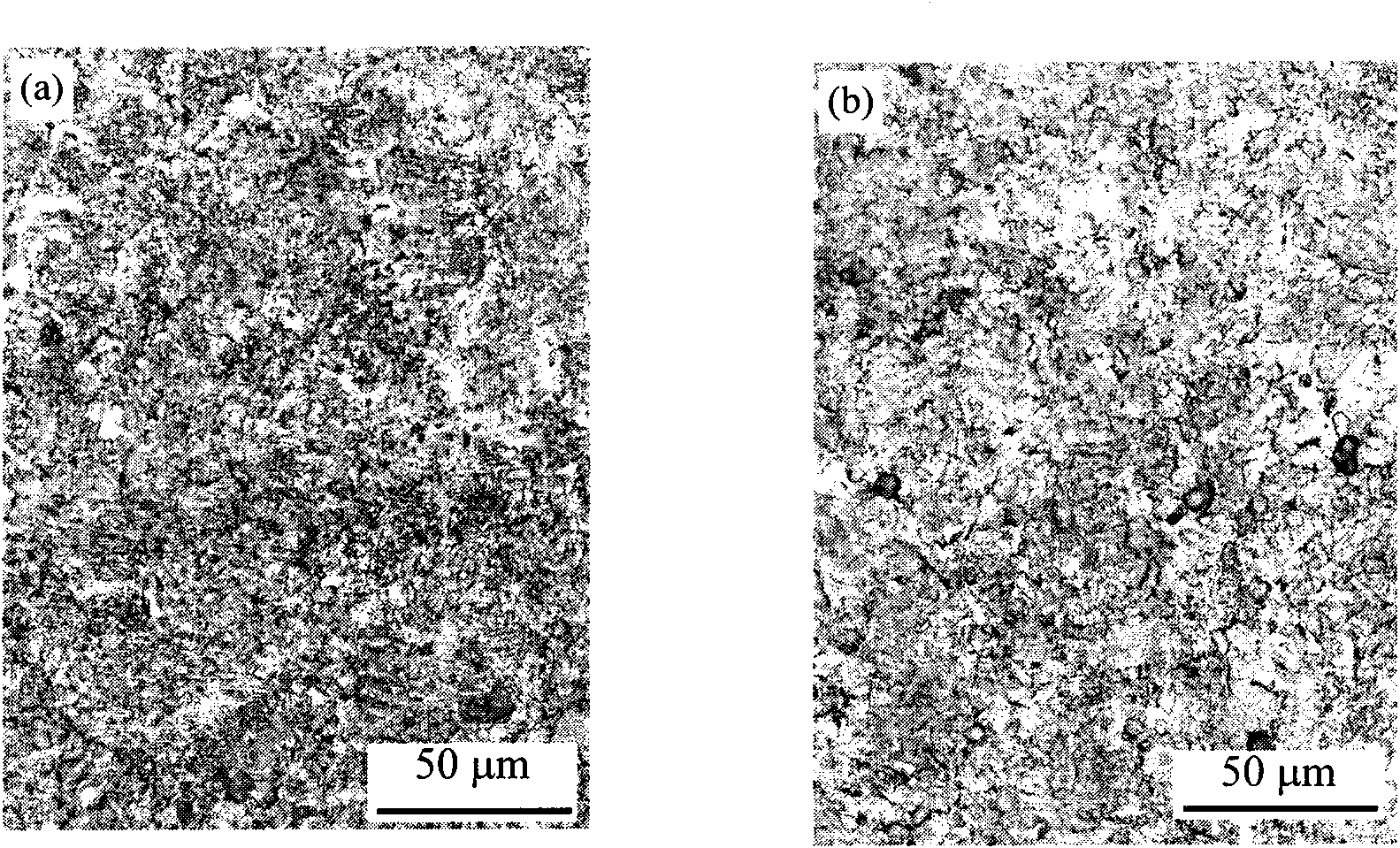

[0029] A titanium alloy integral blade disc, the integral blade disc is composed of a wheel disc and blades, the wheel disc and the blade are integrated, the wheel disc is composed of TC4 titanium alloy, the blade is composed of Ti-48Al-2Cr-2Nb alloy, the wheel disc and Compositional transitions between leaves are straight transitions.

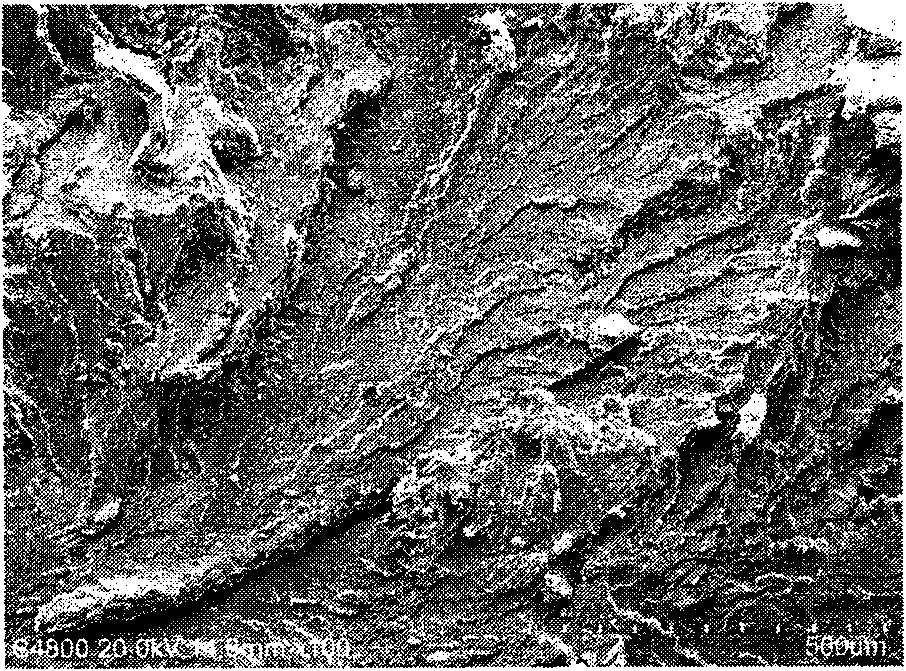

[0030] The manufacturing method of the above-mentioned titanium alloy integral blade disk adopts the laser melting deposition method to laser melt deposit Ti-48Al-2Cr-2Nb alloy blade on the TC4 titanium alloy wheel disk, the steps are as follows,

[0031] (1) TC4 titanium alloy wheel disc is prepared by forging method;

[0032] (2) The Ti-48Al-2Cr-2Nb alloy bar is made into pre-alloyed spherical powder, and the pre-alloyed spherical powder with a particle size of 50-150 μm is screened out, wherein the pre-alloyed spherical powder is atomized by inert gas Method preparation;

[0033](3) in the protective atmosphere box, pre-evacuate low vacuu...

Embodiment 2

[0040] A titanium alloy integral blade disc, the integral blade disc is composed of a disc and blades, the disc and the blade are integrated, the disc is composed of TA12 titanium alloy, and the blade is made of Ti-47Al-2Cr-2Nb-0.2W-0.15B Composed of titanium-aluminum alloy, the composition transition between the disc and the blade is a direct transition.

[0041] The manufacturing method of the above-mentioned titanium alloy integral blade disc adopts the laser melting deposition method to laser melt deposit Ti-47Al-2Cr-2Nb-0.2W-0.15B titanium-aluminum alloy thin-walled blades on the TA12 titanium alloy disc, and the steps are as follows,

[0042] (1) A TA12 titanium alloy wheel was prepared by forging;

[0043] (2) The Ti-47Al-2Cr-2Nb-0.2W-0.15B titanium-aluminum alloy bar is made into pre-alloyed spherical powder, and the pre-alloyed spherical powder with a particle size between 50 and 150 μm is screened out. Among them, the pre-alloyed spherical powder The spherical powde...

Embodiment 3

[0051] A titanium alloy integral blade disc, the integral blade disc is composed of a disc and blades, the disc and the blade are integrated, the disc is composed of TC11 titanium alloy, and the blade is made of Ti-47Al-2Mn-2Nb-0.8TiB 2 Composed of titanium-aluminum alloy, the composition transition between the disc and the blade is a direct transition.

[0052] The manufacturing method of the above-mentioned titanium alloy integral blade disk adopts the laser melting deposition method to laser melt deposit Ti-47Al-2Mn-2Nb-0.8TiB on the TC11 titanium alloy wheel disk 2 Titanium-aluminum alloy thin-walled blades, the steps are as follows,

[0053] (1) A TC11 titanium alloy wheel was prepared by forging;

[0054] (2) Ti-47Al-2Mn-2Nb-0.8TiB 2 Titanium-aluminum alloy rods are made into pre-alloyed spherical powders, and the pre-alloyed spherical powders with a particle size of 50-150 μm are screened out, wherein the pre-alloyed spherical powders are prepared by inert gas atomiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com