Methyl acrylate grafted starch slurry synthesized by ultrasound microwave method

A technology of methyl acrylate and grafted starch, which is applied in the field of textile pulp, and achieves the effects of reducing the cost of pulp, simple method, and simple synthesis method

- Summary

- Abstract

- Description

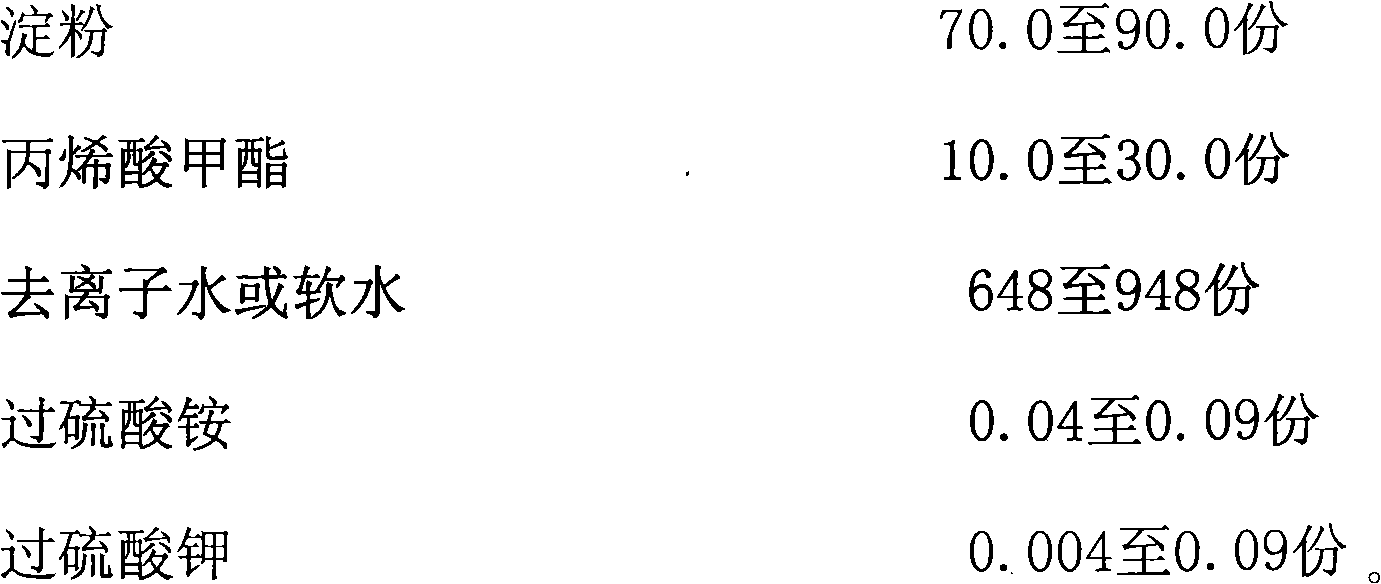

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

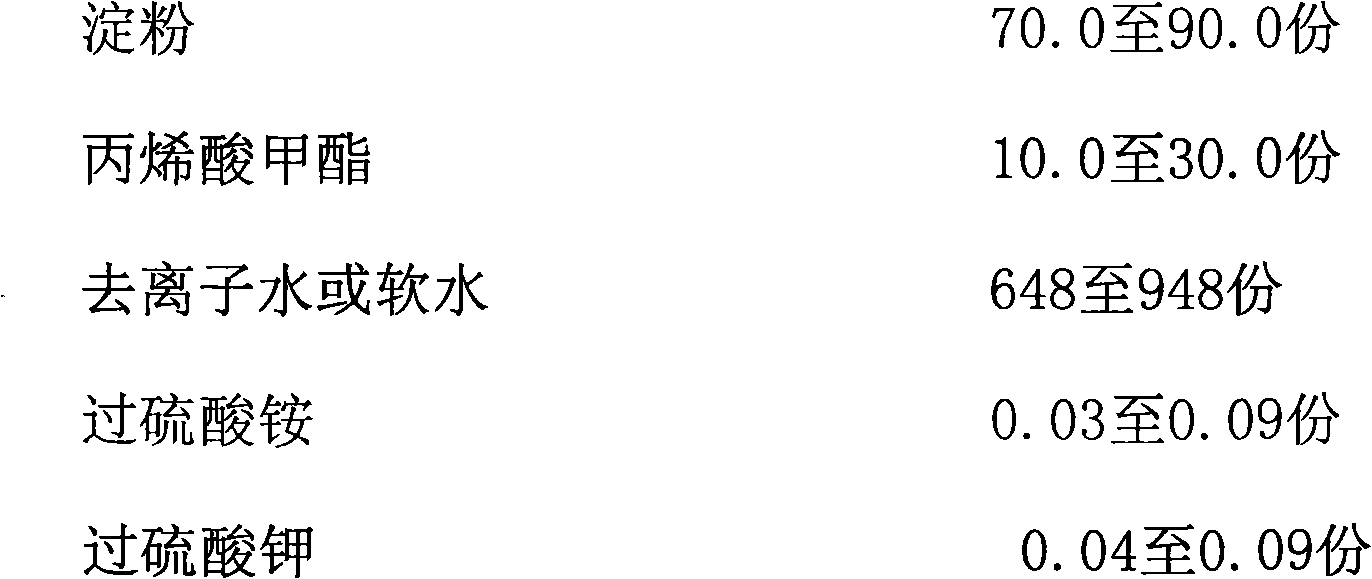

Method used

Image

Examples

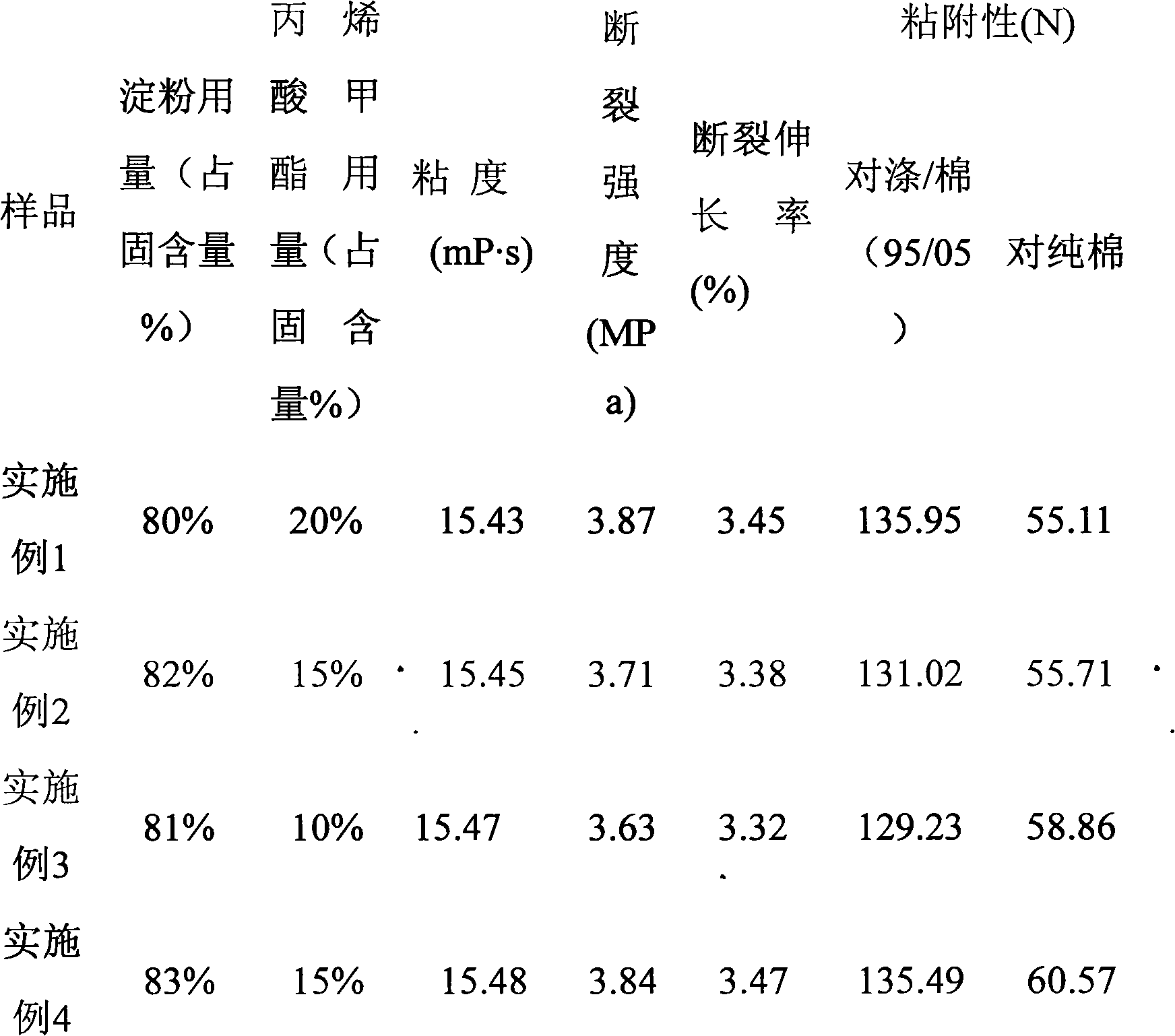

Embodiment 1

[0017] Weigh 80 parts of raw corn starch, add 320 parts of deionized water, stir evenly to form starch milk, ultrasonicate at room temperature for 25 minutes, filter and dry, then add 20 parts of methyl acrylate, 0.031 parts of ammonium persulfate, and 0.09 parts of potassium persulfate , 200 parts of deionized water, fully stirred, placed under a microwave synthesis device, adjusted the power of the microwave oven to control the temperature at 40°C and continued to stir, discharging, cooling, filtering, washing, drying, and pulverizing to obtain powdery methyl acrylate grafted starch. The AM grafted starch was boiled at 95°C for 1 hour, and dried to form a film with a solid content of 6%. Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

Embodiment 2

[0019] Weigh 85 parts of wheat raw starch, add 340 parts of deionized water, stir evenly to form starch milk, ultrasonicate at room temperature for 25 minutes, filter and dry, then add 15 parts of methyl acrylate, 0.038 parts of ammonium persulfate, and 0.007 parts of potassium persulfate , 200 parts of deionized water, fully stirred, placed under the microwave synthesis device, adjusted the power of the microwave oven to control the temperature at 40°C and continued to stir. After 20 minutes of grafting reaction, discharge, cool, filter, wash with water, dry, and pulverize to obtain a powder Methyl acrylate grafted starch. Dried to obtain powdery AM grafted starch. Methyl acrylate grafted starch was boiled at 95° C. for 1 hour and dried to form a film. The solid content of the slurry was 6%.

[0020] Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

Embodiment 3

[0022] Weigh 90 parts of cassava raw starch, add 360 parts of deionized water, stir evenly to form starch milk, ultrasonicate at room temperature for 25 minutes, filter and dry, then add 10 parts of methyl acrylate, 0.056 parts of ammonium persulfate, 0.07 parts of potassium persulfate Parts, 200 parts of deionized water, fully stirred, placed under the microwave synthesis device, adjusted the power of the microwave oven to control the temperature at 40°C and continued to stir. After 20 minutes of grafting reaction, the material was discharged, cooled, filtered, washed, dried, and crushed to obtain a powder Methyl acrylate grafted starch. The AM grafted starch was boiled at 95°C for 1 hour, and dried to form a film with a solid content of 6%.

[0023] Determination of slurry viscosity and mechanical properties of the size film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com