Austenitic stainless steel surface chemical nickel-phosphorus plating method

A technology of austenitic stainless steel and electroless nickel-phosphorus plating, applied in liquid chemical plating, metal material coating process, coating, etc. Destruction and other problems, to achieve the effect of simple process and expansion of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

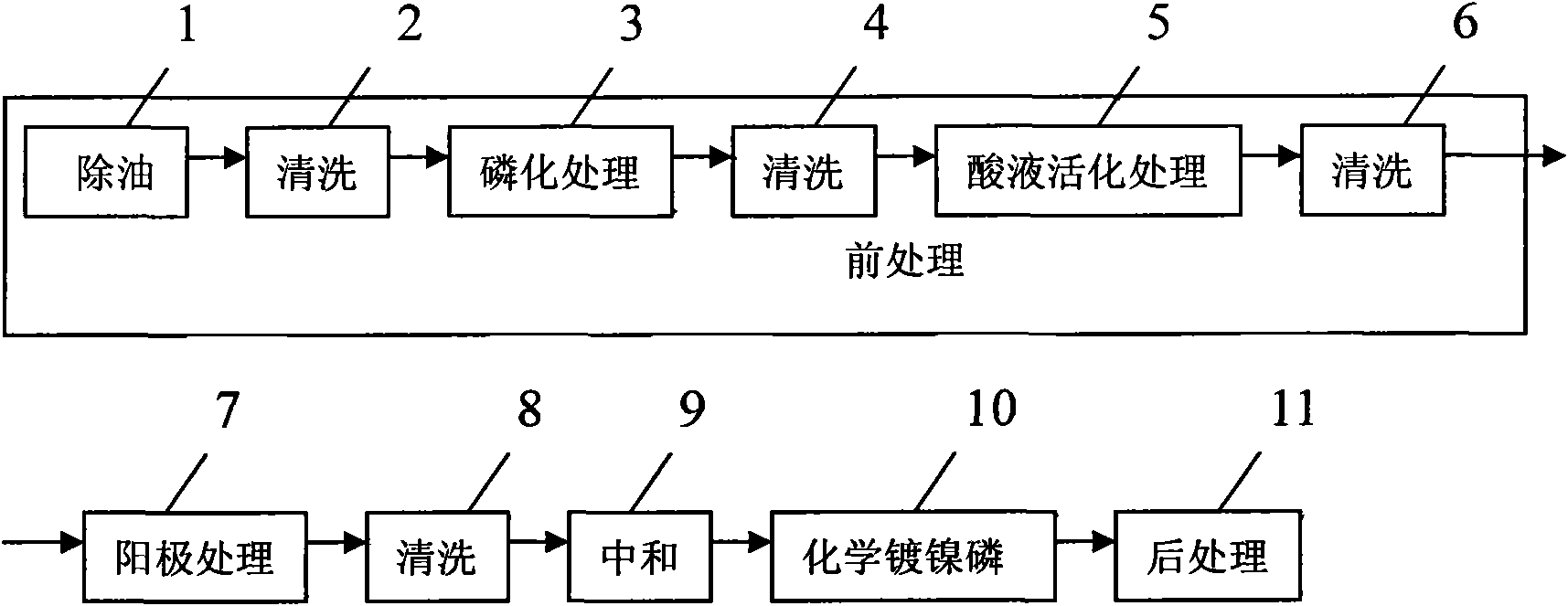

Method used

Image

Examples

Embodiment 1

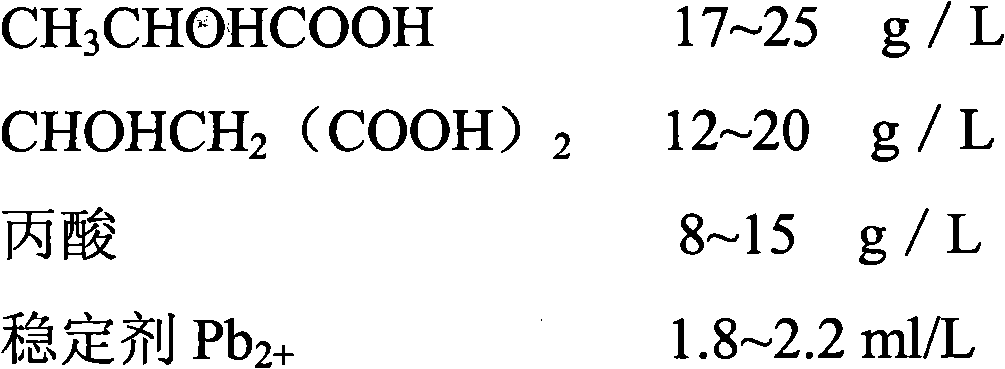

[0040] In this embodiment 1, high-phosphorus electroless nickel plating is carried out on austenitic stainless steel, which specifically includes the following steps:

[0041] A1. Degreasing: Soak austenitic stainless steel in acetone solution for 2 minutes to treat the surface of austenitic stainless steel with oil.

[0042] A2. Rinse the degreased austenitic stainless steel with cold water for 2 minutes.

[0043] A3. Phosphating treatment: Put the austenitic stainless steel into lye and soak for 20min at a temperature of 80°C. The lye contains: NaOH 40g / L, NaOH 2 CO 3 20g / L, Na 3 PO 4 12H 2 O 70g / L, Na 2 SiO 3 10g / L.

[0044] A4. Cleaning: first wash with warm water at 30°C for 2 minutes, then rinse with cold water for 2 minutes.

[0045] A5. Acid activation treatment: put austenitic stainless steel in 50% HCl and 10% H 2 SO 4 Acidification treatment in the mixed solution, temperature: room temperature, etching time: 2min.

[0046] A6. Cleaning: Rinse with pure wa...

Embodiment 2

[0058] The method for electroless nickel-phosphorus plating on the surface of austenitic stainless steel of embodiment 2 is similar to embodiment 1, and its difference from embodiment 1 is that in embodiment 2, medium phosphorus electroless nickel plating solution is used to carry out chemical immersion plating, specifically comprising the following The above steps:

[0059] B1. Degreasing: Soak the austenitic stainless steel in acetone solution for 2 minutes to treat the oil stain on the surface of the austenitic stainless steel.

[0060] B2. Rinse the degreased austenitic stainless steel with cold water for 2 minutes.

[0061] B3. Phosphating treatment: Put the austenitic stainless steel into the lye and soak it for 10 minutes at a temperature of 90°C. The lye contains: NaOH 60g / L, NaOH 2 CO 3 30g / L, Na 3 PO 4 12H 2 O 50g / L, Na 2 SiO 3 5g / L.

[0062] B4. Cleaning: Wash with warm water at 30°C for 3 minutes, then rinse with cold water for 1 minute.

[0063] B5. Acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com