Preparation method of iron-based amorphous coating

A technology of iron-based amorphous and iron-based amorphous alloys, which is applied in the direction of coating, metal material coating technology, fusion spraying, etc., can solve the problems of limited application range, high coating porosity, high spraying cost, etc., to achieve Large application prospects, reduced spraying costs, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

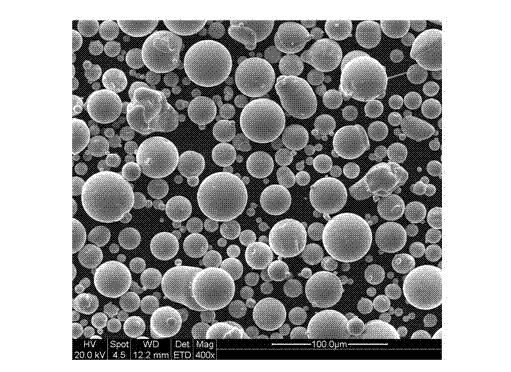

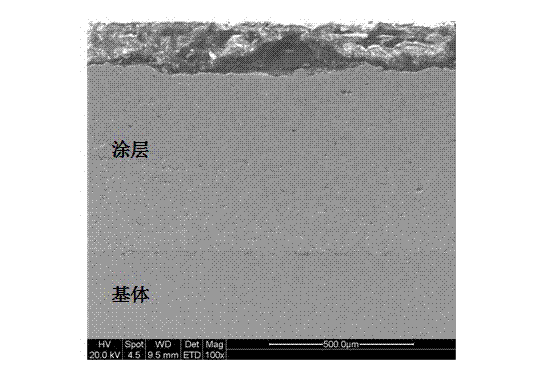

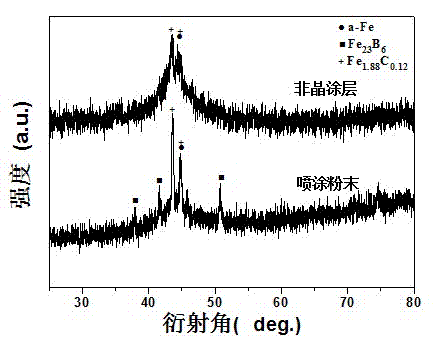

[0029] First, the master alloy is prepared by vacuum induction melting according to the required composition, and the alloy composition is Fe 49.7 Cr 18 mn 1.9 Mo 7.4 W 1.6 B 15.2 C 3.8 Si 2.4 (at.%), the master alloy is put into the atomization furnace, and the amorphous alloy powder is prepared by gas atomization technology. The shape of the powder particles is as figure 1 . It can be seen that most of the powders are spherical and have good fluidity, which is suitable for thermal spraying. X-ray diffraction patterns of powder and coating as figure 2 shown. It can be seen from the figure that both the powder (<45 μm) and the coating are partially amorphous, and the degree of amorphization of the coating is relatively high.

[0030] The iron-based amorphous coating was prepared by the active combustion high-velocity gas (AC-HVAF) spraying process, and the particle size of the sprayed powder was 15-45 μm. The specific spraying process parameters are: air pressure ...

Embodiment 2

[0035] First, the master alloy is prepared by vacuum induction melting according to the required composition, and the alloy composition is Fe 55 Cr 16.2 mn 2.8 Mo 4.5 W 2.6 B 13.5 C 4.3 Si 1.1 (at.%), the master alloy is put into the atomization furnace, and the amorphous alloy powder is prepared by gas atomization technology. The iron-based amorphous coating was prepared by active combustion high-velocity gas (AC-HVAF) spraying process. The specific spraying process parameters are: air pressure 0.4MPa, primary combustion chamber pressure 0.3MPa, secondary combustion chamber pressure 0.2MPa, spraying distance 100mm, powder feeding rate 1rpm.

Embodiment 3

[0037] First, the master alloy is prepared by vacuum induction melting according to the required composition, and the alloy composition is Fe 47.9 Cr 18.8 mn 1.2 Mo 8.7 W 1.3 B 16.6 C 2.1 Si 3.4 (at.%), the master alloy is put into the atomization furnace, and the amorphous alloy powder is prepared by gas atomization technology. The iron-based amorphous coating was prepared by active combustion high-velocity gas (AC-HVAF) spraying process. The specific spraying process parameters are: air pressure 0.8MPa, primary combustion chamber pressure 0.6MPa, secondary combustion chamber pressure 0.4MPa, spraying distance 300mm, powder feeding rate 8rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com