Adamas wafer and production method thereof

A production method and diamond technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost, small application range, small diamond size, etc., and achieve stable performance, low price, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

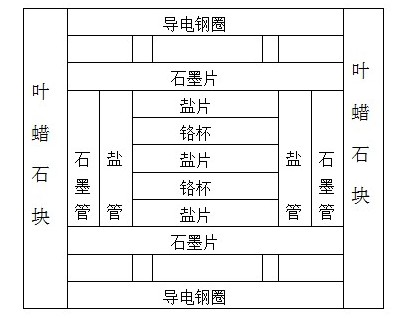

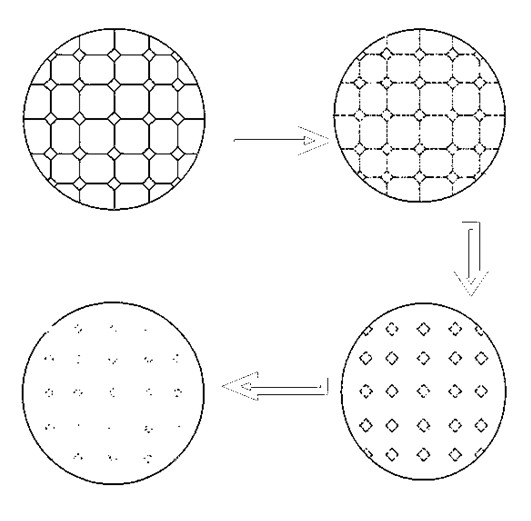

[0031] Embodiment 1: A kind of diamond wafer and production method thereof

[0032] After sieving and selecting the hexahedral diamond abrasive, accurately weigh 10g of 70-80 mesh (about 0.2mm) diamond abrasive, put it in a 1000ml flask, add 2% oleic acid triethanolamine aqueous solution 800ml, Ultrasonic dispersion is used to uniformly disperse the diamond abrasive in the dispersion medium to form a stable dispersed suspension.

[0033] Use negative pressure (0-0.1Pa) to separate the diamond abrasive from the suspension, put it into a porcelain crucible, and dry it in an electric drying oven at 80-110°C for 3-6 hours, so that the surface of the diamond abrasive is basically evenly covered by the dispersion medium ; Then place the diamond abrasives in a clean chromium cup mold (the thickness of the chromium cup mold is 0.13cm), arrange the diamond abrasives tightly through a pressure head with the same inner diameter as the chromium cup, and cover a piece of iron-nickel alloy ...

Embodiment 2

[0042] Embodiment 2: a kind of diamond wafer and production method thereof

[0043] After sieving and selecting the hexahedral diamond abrasive, accurately weigh 10g of 35-40 mesh (about 0.45mm) diamond abrasive, put it in a 1000ml flask, add 800ml of 5% stearic acid ethanol solution, and use Ultrasonic dispersion enables the diamond abrasive to be uniformly dispersed in the dispersion medium to form a stable dispersed suspension. The diamond abrasive is separated from the suspension by negative pressure filtration, put into a porcelain crucible, and the porcelain crucible is dried in an electric heating oven at 100°C for 5 hours to remove the dispersion medium; then the diamond abrasive is placed in In the molybdenum cup, the diamond abrasive is compressed by a pressure head, and a nickel-manganese-cobalt alloy sheet is covered on the diamond layer as a catalyst (nickel accounts for 70%, manganese accounts for 25%, and cobalt accounts for 5%) , Then buckle a molybdenum cup a...

Embodiment 3

[0049] Embodiment 3: A kind of diamond wafer and production method thereof

[0050] After sieving and selecting the hexahedral diamond abrasive, accurately weigh 10g of 18-20 mesh (about 0.9mm) diamond abrasive, put it in a 1000ml flask, add 5% ammonium polyacrylate aqueous solution 400ml and 2% Polyoxyethylene (20) sorbitan monostearate (Tween-60) aqueous solution 400ml, use the method of electric stirring to make the diamond abrasive evenly dispersed in the medium to form a stable dispersed suspension, then add 5% 20ml of oxalic acid aqueous solution destroys the suspension to make it flocculate and settle, centrifuge and dehydrate, dry, and then place it in a vacuum high-temperature furnace, treat it at 500°C for 4 hours under vacuum conditions (<10 Pa), remove the dispersion medium, and then place it in a zirconium cup In the method, after the diamonds are closely arranged and pressed by an indenter, a piece of iron-nickel-cobalt alloy sheet is covered on the diamond layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com