Improved NiO-based resistive random access memory (RRAM) and manufacturing method thereof

A technology of resistive random access and random access memory, applied in the field of memory, can solve the problems of difficulty in reducing the writing voltage, reducing the number of charges, and deteriorating reliability, achieving stable resistance value, avoiding erasing and writing failure, and improving stability and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

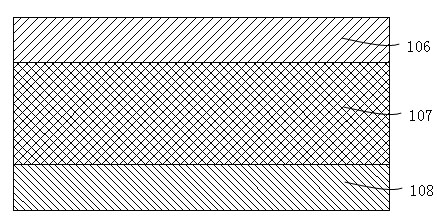

[0027] The silicon dioxide dielectric layer 110 is grown on the monocrystalline silicon 100 layer by means of thermal oxidation or chemical vapor deposition as a substrate. The oxidation temperature is 1100°C, the oxidation time is 10 minutes, and the thickness of the silicon dioxide layer is 100nm-1000nm. The lower electrode metal thin film 201 (Pt is used in this example) is prepared by sputtering growth method. Between the bottom electrode metal film 200 and the silicon dioxide dielectric layer 110, a Ti metal film 200 is grown by sputtering as an adhesion layer of the bottom electrode metal film. A first layer of Al2O3 thin film 310 is prepared on the lower electrode metal thin film 200 by atomic layer deposition (ALD), with a thickness of 2-6 nm. A layer of NiO thin film 311 is prepared on the first layer of Al2O3 thin film by physical va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com