Bicomponent condensed type room temperature vulcanization silicon rubber

A room temperature vulcanization and condensation type technology, applied in the field of silicone rubber, can solve the problems of poor electrical performance, non-curing, and low shrinkage, and achieve good aging resistance, good bonding performance, and good initial electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

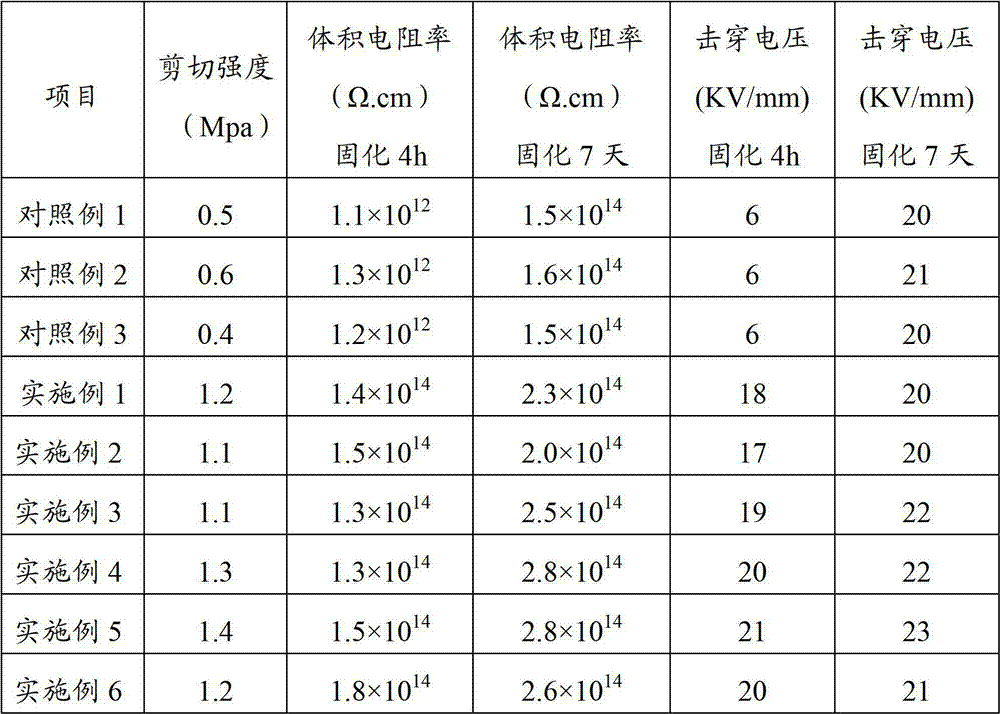

Examples

Embodiment 1

[0023] A component 170g, B component 7.1g.

[0024] Component A: Weigh 100 g of 5000 mPa.s hydroxyl-terminated polydimethylsiloxane, 10 g of 50 mPa.s dimethyl silicone oil, and 60 g of heavy calcium carbonate. After premixing, grind 3 times with a three-roll mill.

[0025] Component B: 5 g of ethyl orthosilicate, 2 g of γ-isocyanatopropyl trimethoxysilane, 0.1 g of dibutyltin dilaurate, mixed for 15 minutes under nitrogen protection.

Embodiment 2

[0027] A component 250g, B component 16g.

[0028] Component A: Weigh 100g of 80000mPa.s hydroxyl-terminated polydimethylsiloxane, 50g of 2000mPa.s dimethyl silicone oil, and 100g of silicon micropowder. After premixing, grind 3 times with a three-roll mill.

[0029] Component B: 10 g of tetraethyl orthosilicate, 5 g of γ-isocyanatopropyl trimethoxysilane, 1 g of dibutyltin diacetate, mixed for 15 minutes under nitrogen protection.

Embodiment 3

[0031] A component 210g, B component 11.5g.

[0032] Component A: Weigh 100 g of 20000 mPa.s hydroxyl-terminated polydimethylsiloxane, 30 g of 1000 mPa.s dimethyl silicone oil, and 80 g of aluminum oxide. After premixing, grind 3 times with a three-roll mill.

[0033] Component B: 7.5 g of propyl orthosilicate, 3.5 g of γ-isocyanatopropyl triethoxysilane, 0.5 g of stannous octoate, mixed for 15 minutes under nitrogen protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com