Front silver paste for crystalline silicon solar battery plate and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of silver paste shrinkage, thin line resolution, aspect ratio, etc., to reduce shrinkage, increase contact area, and strengthen conductive pathways Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

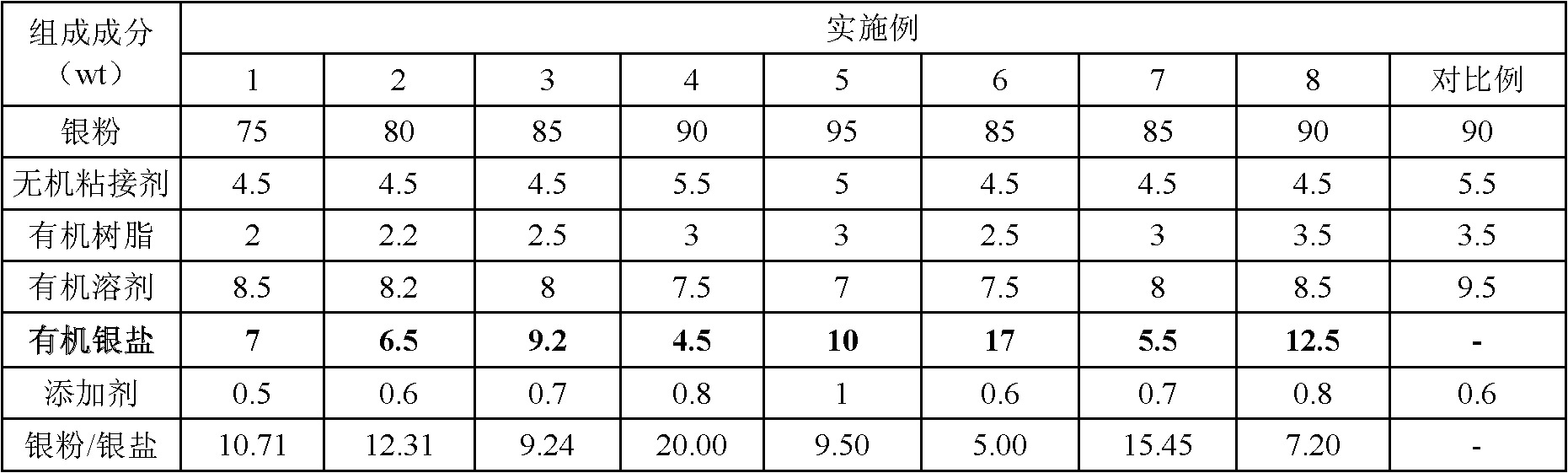

[0026] The present invention is used for the silver paste embodiment of crystalline silicon solar cell front face and sees the following table (table one, table two):

[0027] Table I

[0028]

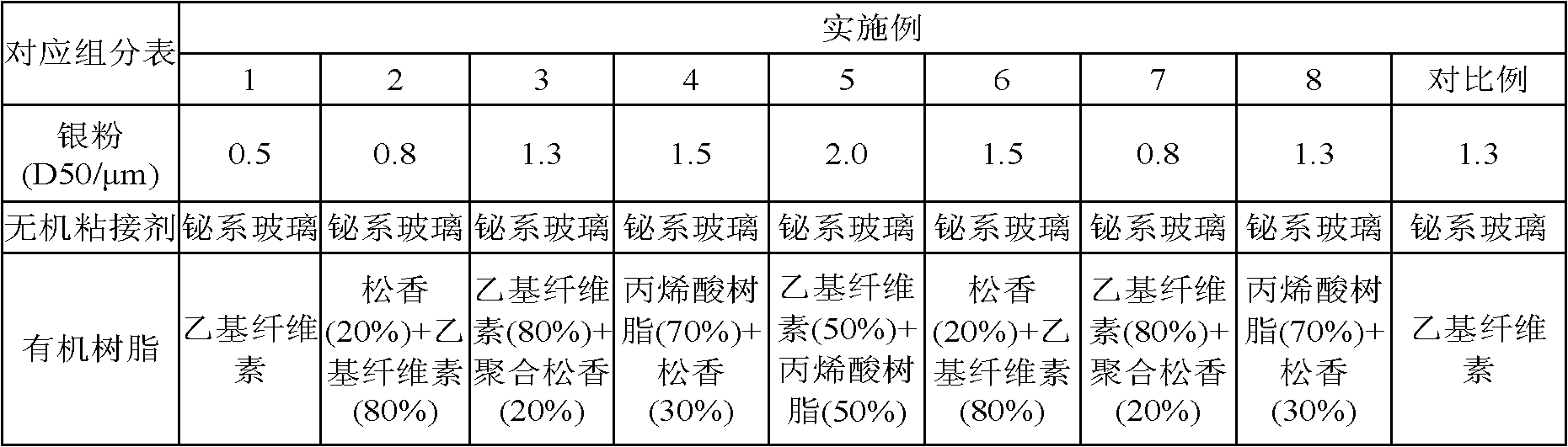

[0029] Table II

[0030]

[0031]

[0032] According to the above formula requirements, silver powder, inorganic binder, organic resin, organic solvent, organic silver salt and additives are stirred to form a uniform paste-like semi-fluid, and then rolled on a three-roll mill until it becomes uniform and has good fluidity The slurry has a fineness of ≤5 microns and a viscosity between 200,000-280,000mPa.s.

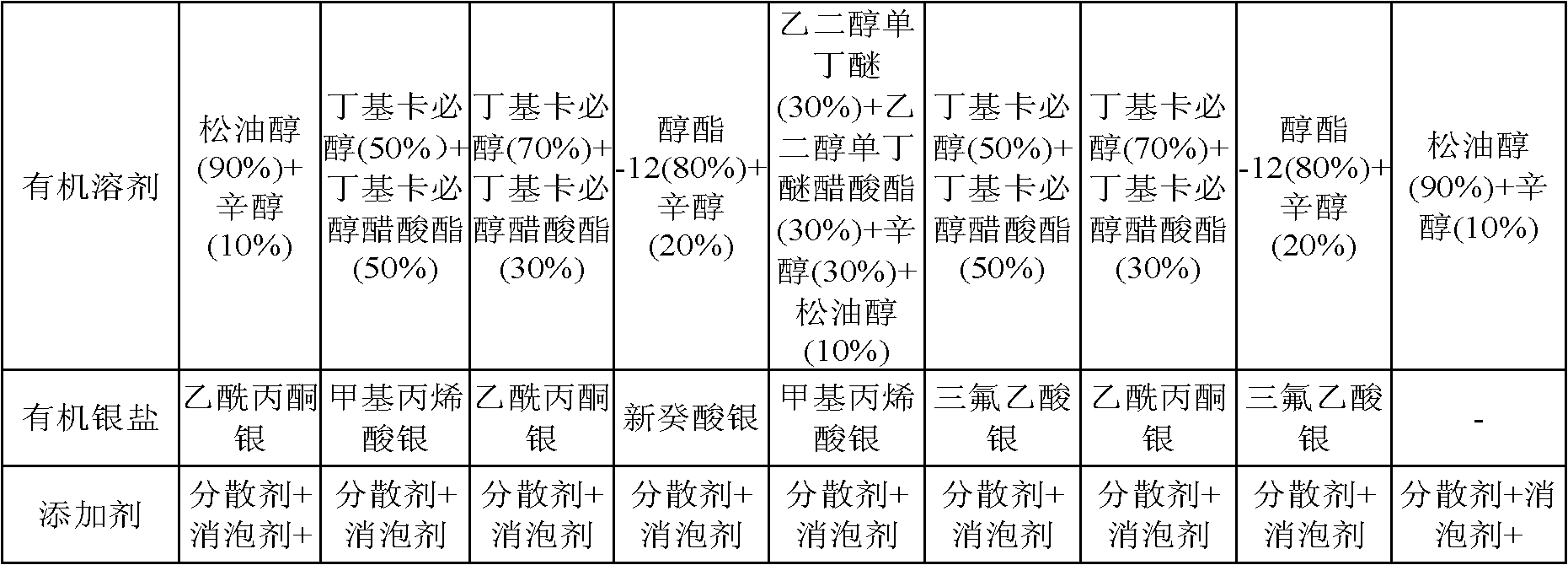

[0033] The performance parameters of the silver paste used for the front side of the crystalline silicon solar cell sheet produced according to the foregoing embodiments are as follows (table three):

[0034] Table three

[0035]

[0036] According to the above experimental results, it can be known that the performance parameters of Examples 1-8 are significantly imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com