Preparation method of concentrating solar cell chip capable of preventing edge leakage

A technology for solar cells and edge leakage, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of rough surface of cutting edge, difficulty in depositing passivation film, difficulty in forming passivation film, etc., to achieve excellent passivation edge, High quality and reflective performance, anti-destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

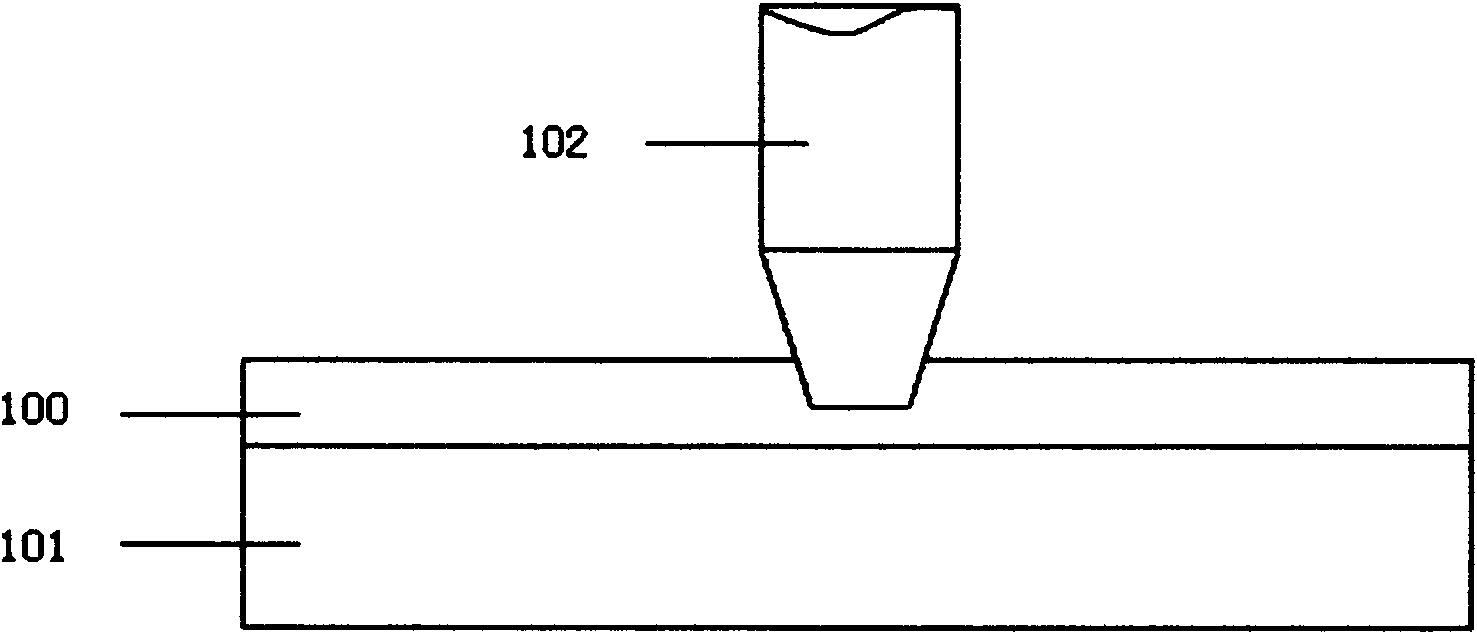

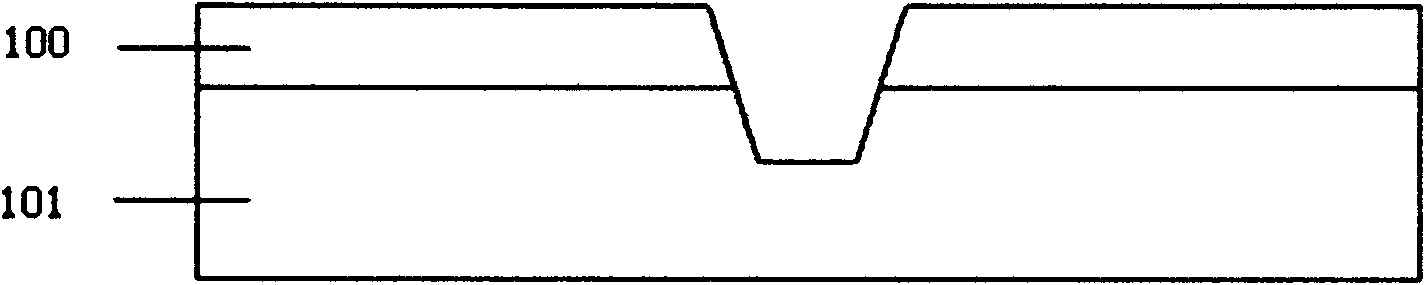

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] A method for manufacturing a concentrated solar cell chip that prevents edge leakage, the process steps are:

[0015] Such as figure 1 As shown, use acetone and isopropanol to ultrasonically remove the surface contamination of the chip, rinse with a large amount of deionized water, remove the surface oxide layer with a mixed solution of citric acid, hydrogen peroxide or sulfuric acid, and hydrogen peroxide to expose a fresh surface, blow dry with nitrogen, and dry ;

[0016] After gluing, pre-baking, exposure, post-baking, developing, rinsing, film hardening and other steps, photolithography of the front electrode pattern;

[0017] The front electrode metal is evaporated by electron beam evaporation or magnetron sputtering;

[0018] Ultrasonic stripping of metal in acetone solution to form a positive electrode pattern;

[0019] Remove the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com