Method for producing laccase by fermenting Shiraia bambusicola

A technology of bamboo yellow fungus and laccase, applied in the field of bioengineering, can solve problems such as no research report on bamboo yellow fungus, can not meet the enzyme amount, long fermentation period, etc., and achieves high medicinal value, short fermentation period and high health care. effect of efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

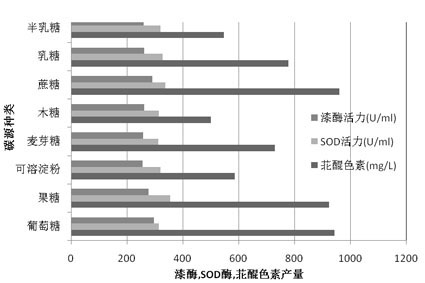

[0035] The composition of the medium is: carbon source 20g / L, potato 200g / L, peptone 20g / L, NH 4 NO 3 10g / L, corn syrup powder 12g / L, K 2 HPO 4 2 g / L, KH 2 PO 4 2 g / L, natural pH, 10% inoculum size, 24 hours seed age, 30 ℃ fermentation temperature, 300L airlift fermenter, 70% liquid volume, 1:1.5 v / v / m ventilation, The fermentation time is 3 days. Under these conditions, 8 batches of fermentation were carried out, and the carbon sources used in each batch of fermentation were different, which were glucose, fructose, soluble starch, maltose, xylose, sucrose, lactose, and galactose in sequence, and the concentration of each batch of carbon sources was 20g / L. The yields of laccase, SOD and perylenequinone pigments were as follows: figure 1 shown.

Embodiment 2

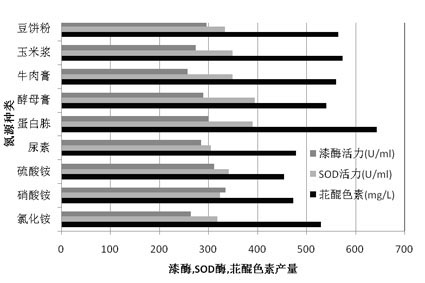

[0037] The composition of the medium is: glucose 20g / L, nitrogen source 30g / L, K 2 HPO 4 4 g / L, KH 2 PO 4 4 g / L, natural pH, 5% inoculum volume, 48 hours of seed age, 24 ℃ fermentation temperature, 300L airlift fermenter, 60% liquid volume, 1:1.5 v / v / m ventilation volume, The fermentation time is 3 days. Under these conditions, 9 batches of fermentation were carried out. The nitrogen sources used in each batch of fermentation were different, followed by ammonium chloride, ammonium nitrate, ammonium sulfate, urea, peptone, yeast extract, beef extract, corn steep liquor, soybean cake powder, and each batch of nitrogen source The concentration is 30g / L. The yields of laccase, SOD and perylenequinone pigments were as follows: figure 2 shown.

Embodiment 3

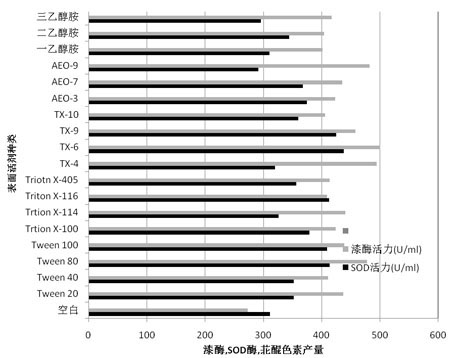

[0039] The composition of the medium is: glucose 20g / L, NH 4 NO 3 10g / L, KH 2 PO 4 4 g / L, peptone 10g / L, surfactant 0.08g / L, pH natural. The inoculum size was 10%, the seed age was 15 hours, the culture temperature was 28 °C, the 50L mechanically stirred fermenter, the liquid volume was 60%, the ventilation rate was 1:0.5 v / v / m, and the stirring speed was 150 r / min. The time is 3 days. When the fermentation starts, the surfactant is added to the fermentation broth immediately. Under this condition, 18 batches of fermentation were carried out, and the surfactants used in each batch of fermentation were different, which were Tween 20, Tween 40, Tween 60, Tween 80, Triton X-100, TritonX-114, TritonX-116, Triton X-405 , TX-4, TX-6, TX-9, TX-10, AEO-3, AEO-7, AEO-9, monoethanolamine, diethanolamine, triethanolamine, each batch of surfactant concentration is 0.08g / L. The yields of laccase, SOD and perylenequinone pigments were as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com