Insulating coil coating and preparation method thereof

A technology of coil coating and solar heat, applied in polyester coating, reflective/signal coating, coating, etc., to achieve cost saving, heat insulation and energy saving effect, and improve economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

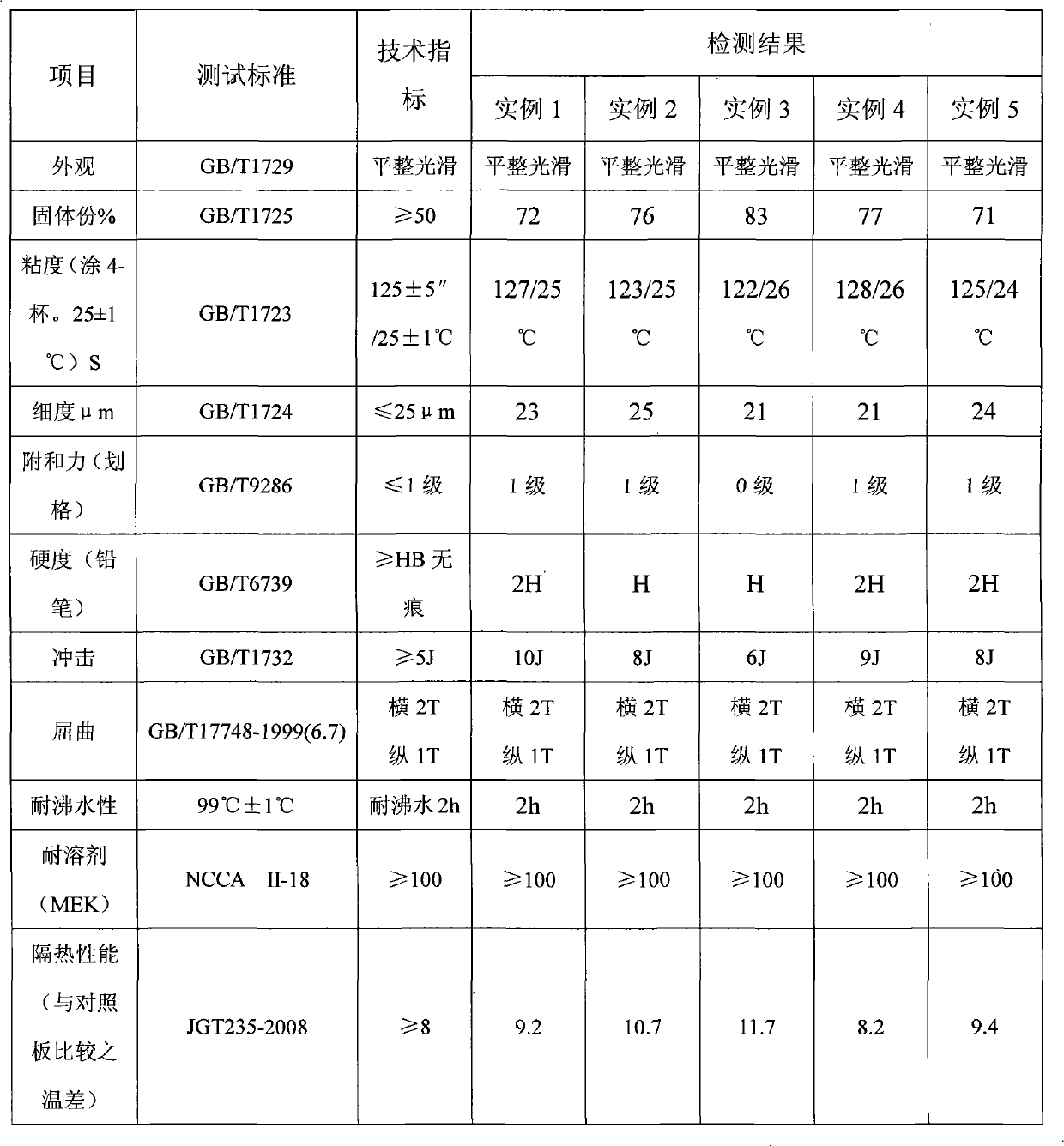

Examples

Embodiment 1

[0057] Modification of potassium titanate whiskers: In terms of mass fraction, add 60 parts of 95% ethanol to the reaction vessel, adjust the pH value of 95% ethanol to 3.0 with glacial acetic acid, and then add 2 parts of silane coupling agent KH560 to acidify In an aqueous ethanol solution, mechanically stir at 300 rpm for 15 minutes. Then 30 parts of potassium tetratitanate whiskers were added to the above solution, mechanically stirred at 300 rpm for 2 hours, then filtered and dried to obtain functional potassium titanate whiskers, and the filtrate could be reused.

[0058] Preparation of Insulation Coil Coatings:

[0059] Step 1: Adjust the rotating speed of the adjustable frequency conversion speed regulating dispersing machine to 500 rpm and then turn on the switch. At a low shear speed, add the mixed solvent (cyclohexanone: S-100 : Propylene glycol ethyl ether: DBE: Ethylene glycol ethyl ether acetate = 3.5: 3.5: 1: 1: 1), saturated polyester resin (Degussa L411), ami...

Embodiment 2

[0075] Modification of potassium titanate whiskers: In terms of mass fraction, add 80 parts of 97% ethanol to the reaction vessel, adjust the pH value of 97% ethanol to 1.0 with sulfuric acid, and then add 2 parts of silane coupling agent KH570 to the acidified In 97% ethanol, mechanically stir at 300 rpm for 15 minutes. Then 50 parts of potassium hexatitanate whiskers were added to the above solution, mechanically stirred at 300 r / min for 1 hour, then filtered and dried to obtain functional potassium titanate whiskers, and the filtrate could be reused.

[0076] Preparation of Insulation Coil Coatings:

[0077] Step 1: Adjust the rotating speed of the adjustable frequency conversion speed regulating dispersing machine to 600 rpm and then turn on the switch. At a low shear speed, add the mixed solvent (cyclohexanone: S-100 : Propylene Glycol Ether: DBE: Ethylene Glycol Ether Acetate = 3.5: 3.5: 1: 1: 1), saturated polyester resin (Degussa LH820-50), amino resin and solar heat ...

Embodiment 3

[0093] Modification of potassium titanate whiskers: In terms of mass fraction, add 90 parts of 99% ethanol to the reaction vessel, adjust the pH value of 99% ethanol to 2.0 with hydrochloric acid, and then add 2 parts of silane coupling agent to the acidified ethanol , mechanically stirred at 300 rpm for 15 minutes. Then 25 parts of potassium octatitanate whiskers were added to the above solution, mechanically stirred at 300 rpm for 2 hours, then filtered and dried to obtain functional potassium titanate whiskers, and the filtrate could be reused.

[0094] Preparation of Insulation Coil Coatings:

[0095] Step 1: Adjust the rotating speed of the adjustable frequency conversion speed regulating dispersing machine to 500 rpm and then turn on the switch. At a low shear speed, add the mixed solvent (cyclohexanone: S-100 : propylene glycol ethyl ether: DBE: ethylene glycol ethyl ether acetate = 3.5: 3.5: 1: 1: 1), saturated polyester resin (BASF Desmophen T 1665), amino resin and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com