Novel high-efficiency refining catalytic aid and preparation method thereof

A catalytic aid and high-efficiency technology, applied in chemical instruments and methods, physical/chemical process catalysts, catalytic cracking, etc., can solve the problems of aggravated environmental pollution, large catalyst consumption, and increased operating costs, and achieve a large catalytic area , Improve the quality of refined oil and increase the yield of gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

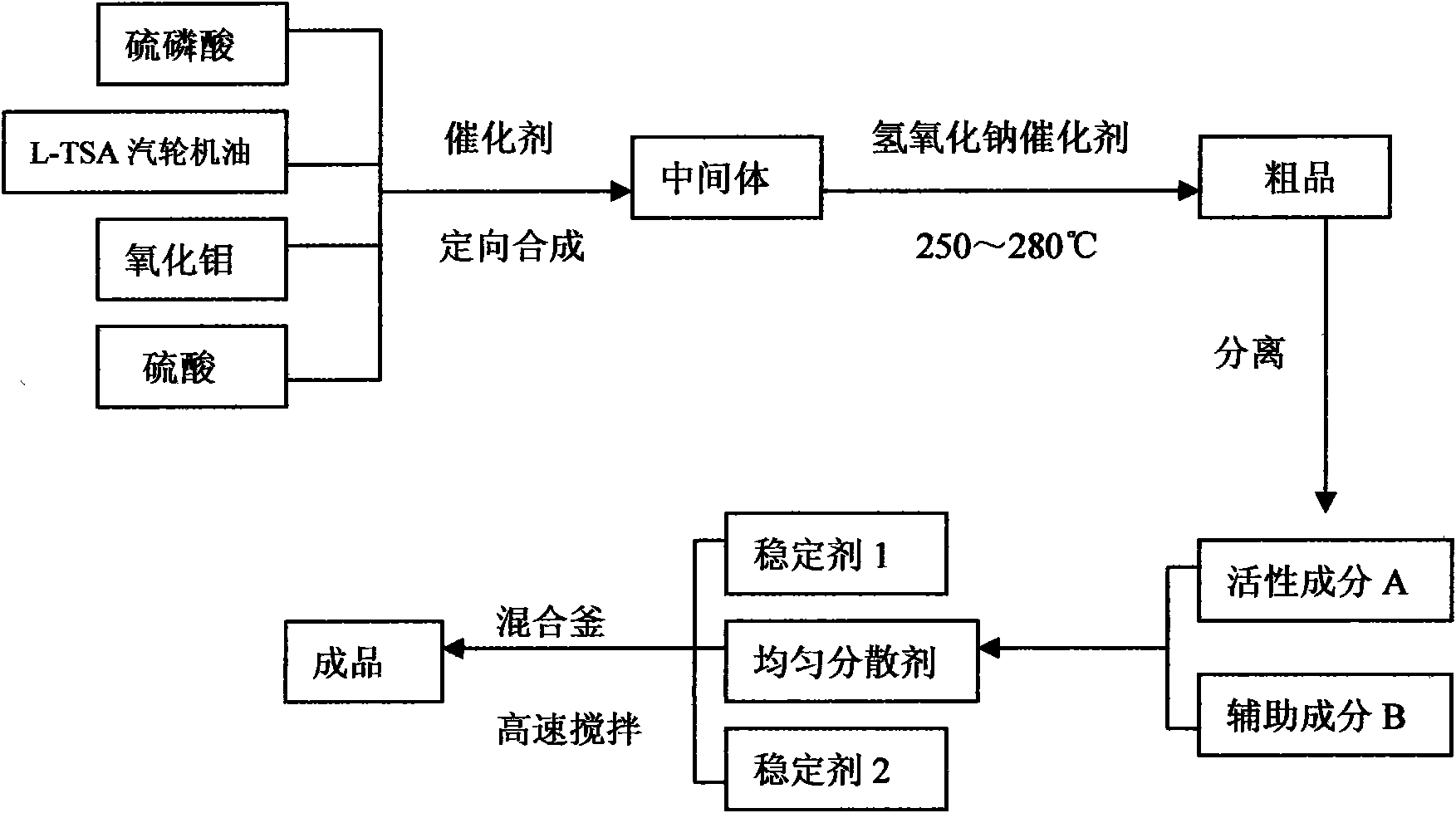

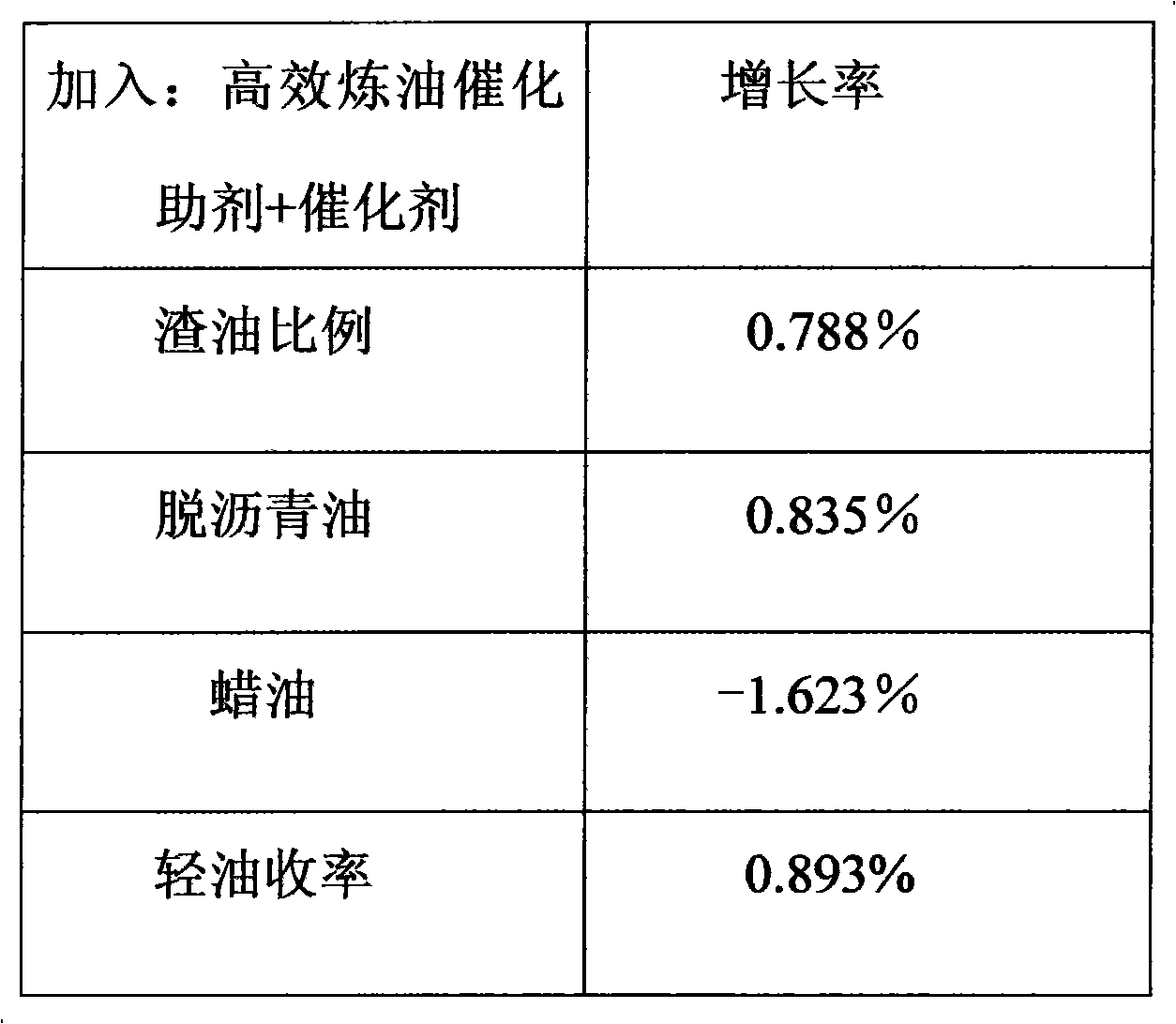

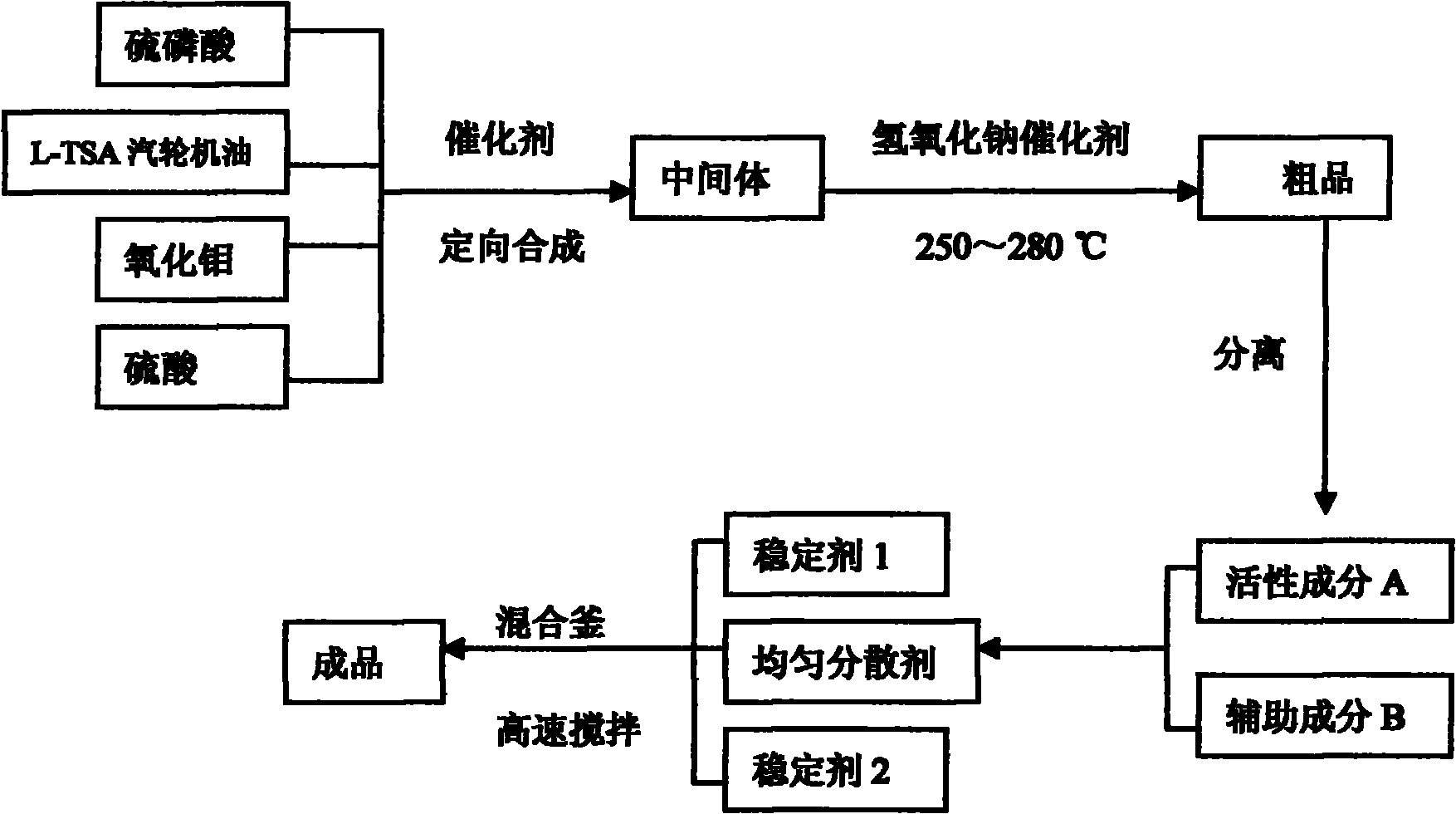

[0030] Refer to attached figure 1 , a new type of high-efficiency oil refining catalytic aid and its preparation method. The preparation process mainly includes: the preparation of intermediates, the preparation of crude products, and the preparation of finished products. With the help of its acidity, surface activity and the synergistic effect of rare earth metals, the light oil yield aid can improve the acidity of B acid, hydrogen transfer reaction activity and viscosity of feedstock oil of the main catalyst, thereby effectively improving the activity, selectivity and The effect of atomization and vaporization of feedstock oil can further promote the ideal reaction of catalytic cracking and increase the yield of LPG+gasoline+diesel. The difference is that the total liquid recovery is increased above 0.8% (ω).

[0031] Example 1: Preparation of high-efficiency oil refining catalyst aids

[0032] 15%-20% sulfuric acid, 5%-10% molybdenum oxide, 40%-50% L-STA steam turbine oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com