Method for preparing carbon nano-tubes by using biological product as catalyst precursor

A biological product, carbon nanotube technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of high cost, complex preparation process, large consumption of chemical reagents, etc., achieve low cost, simple preparation process, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

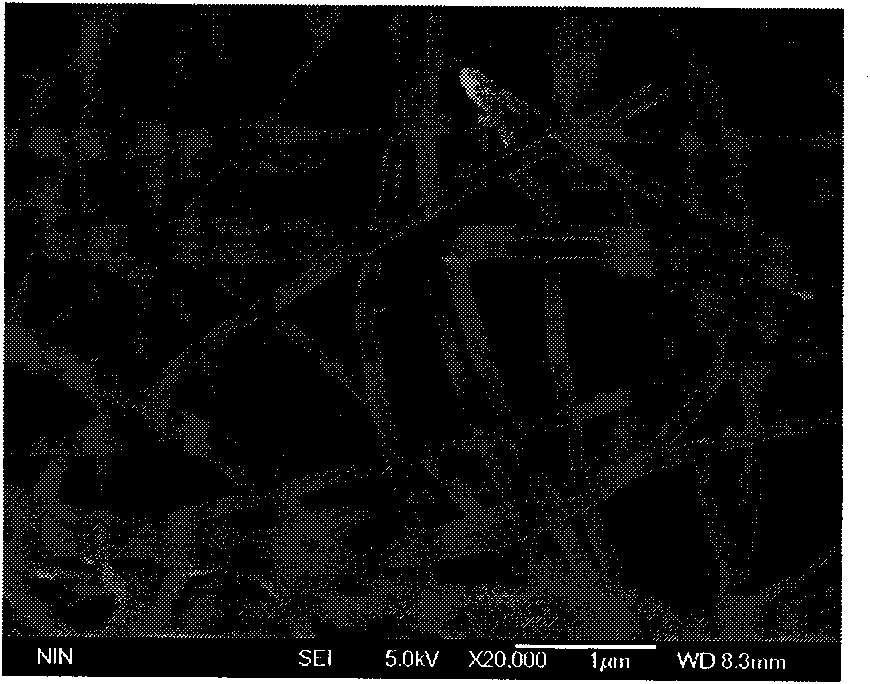

[0014] Embodiment 1: Clean the black fungus, remove the moisture, grind after drying, the grinding time is 20 minutes, and obtain the catalyst precursor powder; put the powder into the chemical vapor deposition furnace, under the protection of argon The temperature was raised to 800°C within 4 hours, and then the mixed gas of argon and natural gas with a volume ratio of 10:1 was passed into the chemical vapor deposition furnace, and the flow rate of the gas was 160 ml / min. Cool to room temperature under the protection of argon to obtain a black powder; react the obtained black powder with a sulfuric acid solution with a hydrogen ion concentration of 2 mol / L for 40 minutes, and then wash it with distilled water to neutrality to obtain high-purity nano-carbon tubes, the resulting carbon nanotubes as figure 1 shown.

Embodiment 2

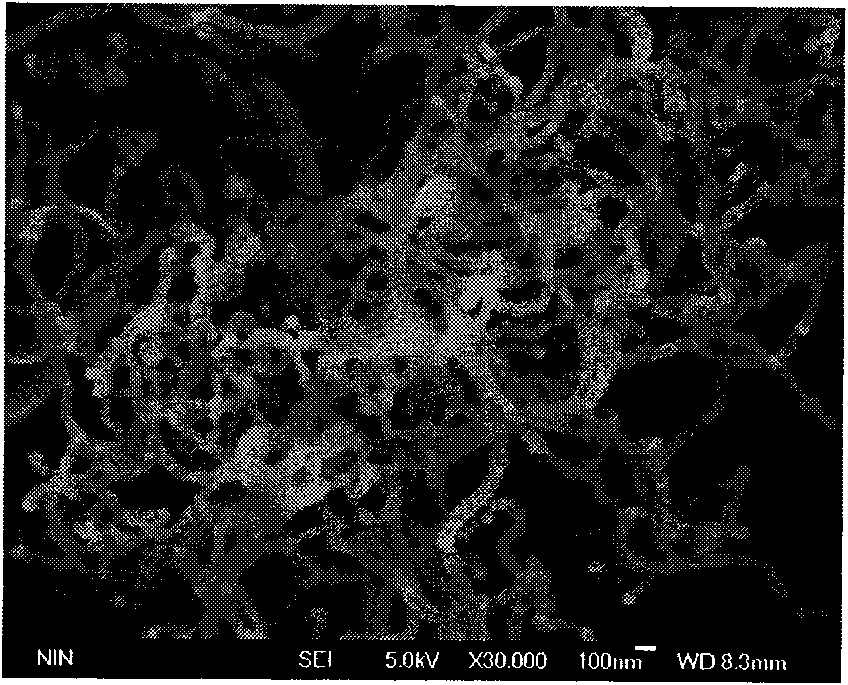

[0015] Example 2: Clean the black sesame, remove the moisture, grind after drying, the grinding time is 10 minutes, and obtain the catalyst precursor powder; put the powder into a chemical vapor deposition furnace, under the protection of argon The temperature was raised to 1100°C within 6 hours, and then the mixed gas of argon and natural gas with a volume ratio of 8:1 was passed into the chemical vapor deposition furnace, the gas flow rate was 100 ml / min, and the reaction was carried out at 1100°C for 30 minutes. Cool to room temperature under the protection of argon to obtain a black powder; react the obtained black powder with a nitric acid solution with a hydrogen ion concentration of 6 mol / liter for 20 minutes, and then wash it with distilled water to neutrality to obtain high-purity nano-carbon tubes, the resulting carbon nanotubes as figure 2 shown.

Embodiment 3

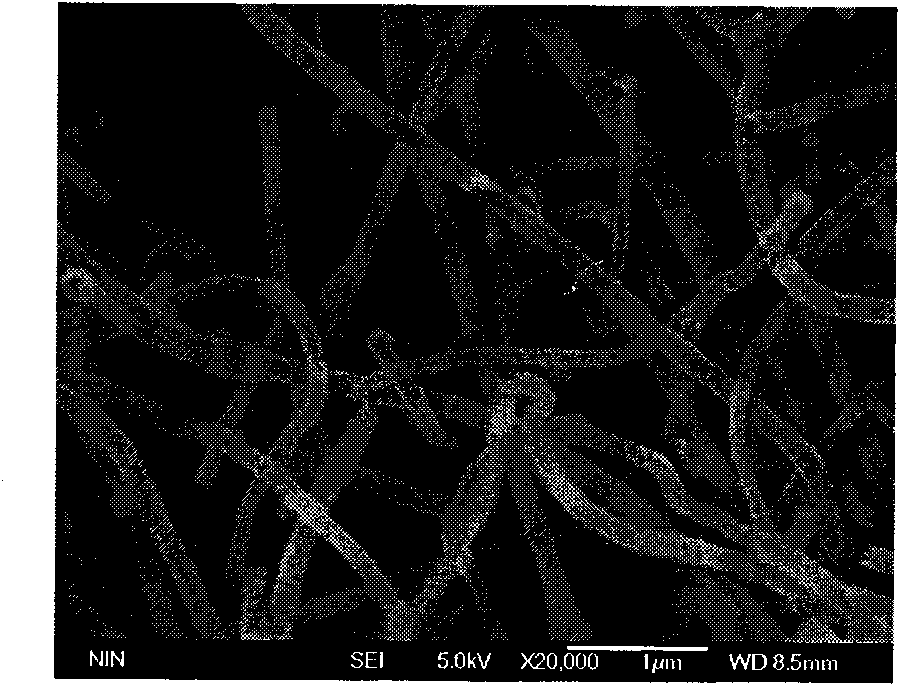

[0016] Example 3: Pig blood was cleaned, dehydrated, dried, and ground for 40 minutes to obtain catalyst precursor powder; the powder was put into a chemical vapor deposition furnace, and under the protection of argon The temperature was raised to 1000°C within 5 hours, and then the mixed gas of argon and natural gas with a volume ratio of 6:1 was passed into the chemical vapor deposition furnace, and the flow rate of the gas was 70 ml / min. Cool to room temperature under the protection of argon to obtain a black powder; react the obtained black powder with a hydrochloric acid solution with a hydrogen ion concentration of 3 mol / liter for 30 minutes, and then wash it with distilled water to neutrality to obtain high-purity nano-carbon tubes, the resulting carbon nanotubes as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com