Nickel-based high temperature solder and preparation method thereof

A high-temperature brazing filler metal and nickel-based technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of violent reaction and poor mechanical properties of joints, and achieve good wettability, good mechanical properties, and simple preparation process reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode one: the nickel-based high-temperature brazing filler metal of this embodiment is made up of Si powder of 9%~11%, TiH of 0~15% by mass percentage 2 powder and the rest of Ni powder.

[0016] The form of the nickel-based high-temperature solder in this embodiment is uniformly mixed powder.

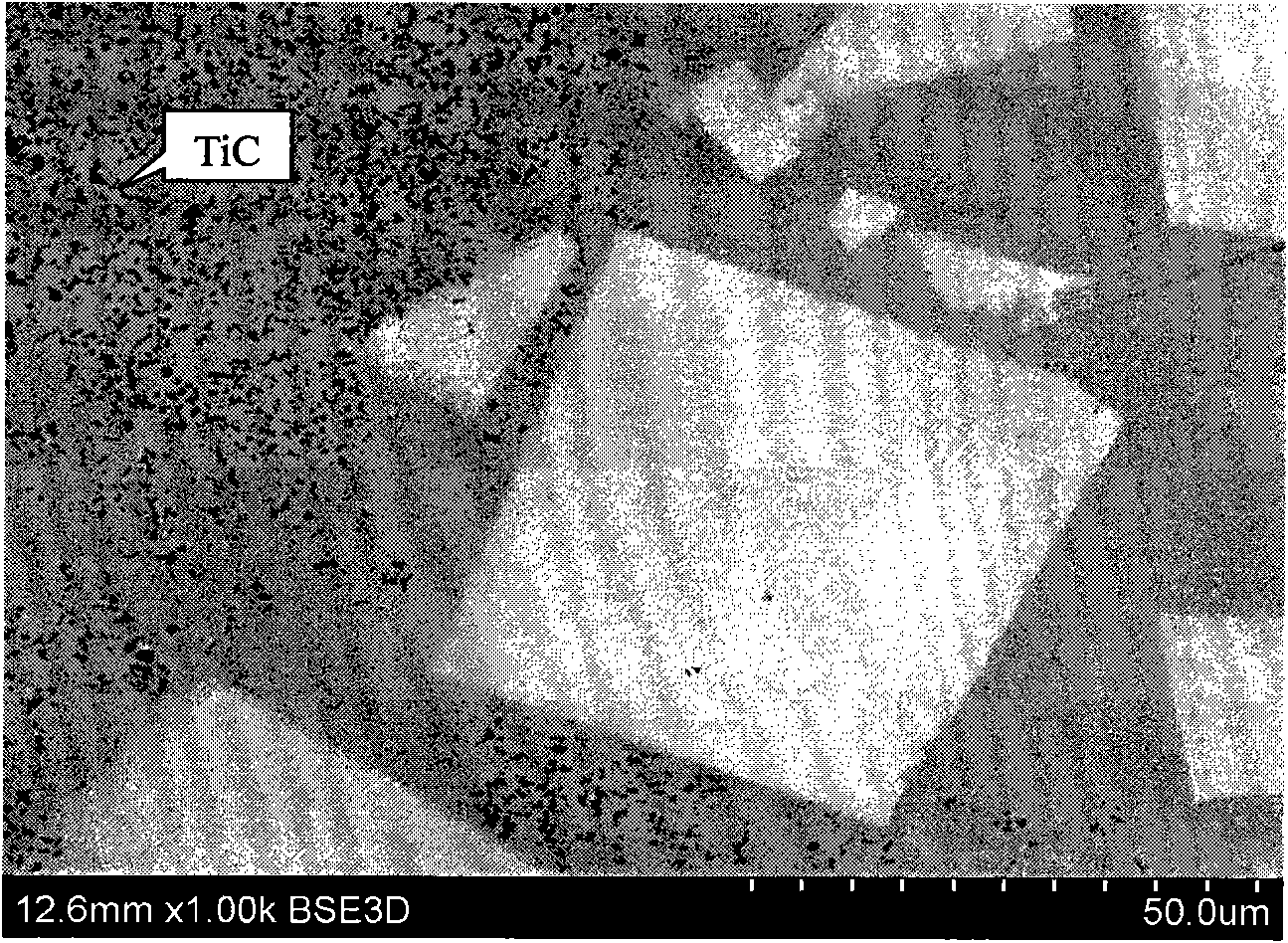

[0017] In this embodiment, the nickel-based high-temperature brazing filler metal is based on the binary eutectic composition of Ni powder and Si powder, and has a high Si content, which can effectively inhibit the reaction of Ni and SiC ceramic phase in the C / SiC composite material, and inhibit the brazing joint. A brittle graphitic carbon layer is produced in the Adding a certain amount of Ti can not only improve the wettability of nickel-based high-temperature solder, but also the Ti element can form a dispersed TiC second phase particle phase in the brazing joint structure, relieve the thermal stress of the joint, optimize the joint structure, and im...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass purity of Si in the nickel-based high-temperature solder is 99.0% to 99.9%, and the TiH 2 The mass purity of Ni is 99.0% to 99.9%, and the mass purity of Ni is 99.0% to 99.9%. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the nickel-based high-temperature solder is made of 9% to 11% Si powder and the remainder Ni powder in mass percentage. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

[0023] Using the brazing method described in the first specific embodiment, the room temperature shear strength of the joint obtained by brazing the C / SiC composite material and the GH99 nickel-based ultra-high temperature alloy with the nickel-based high-temperature solder of this embodiment is 80MPa-88MPa The room temperature shear strength of the joint obtained by brazing the C / C composite material and the GH99 nickel-based ultra-high temperature alloy with the nickel-based high-temperature solder of this embodiment is 2MPa-3MPa.

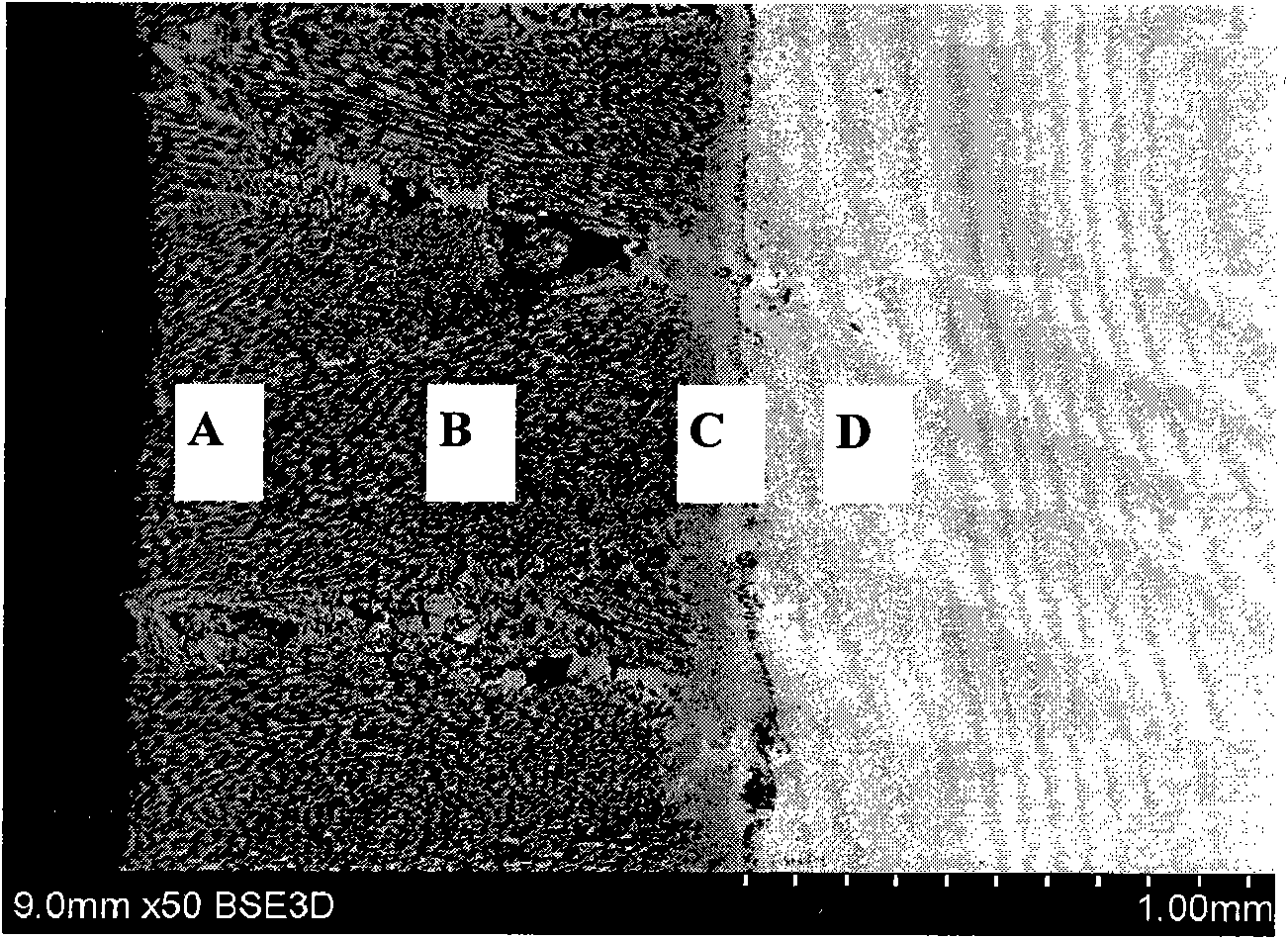

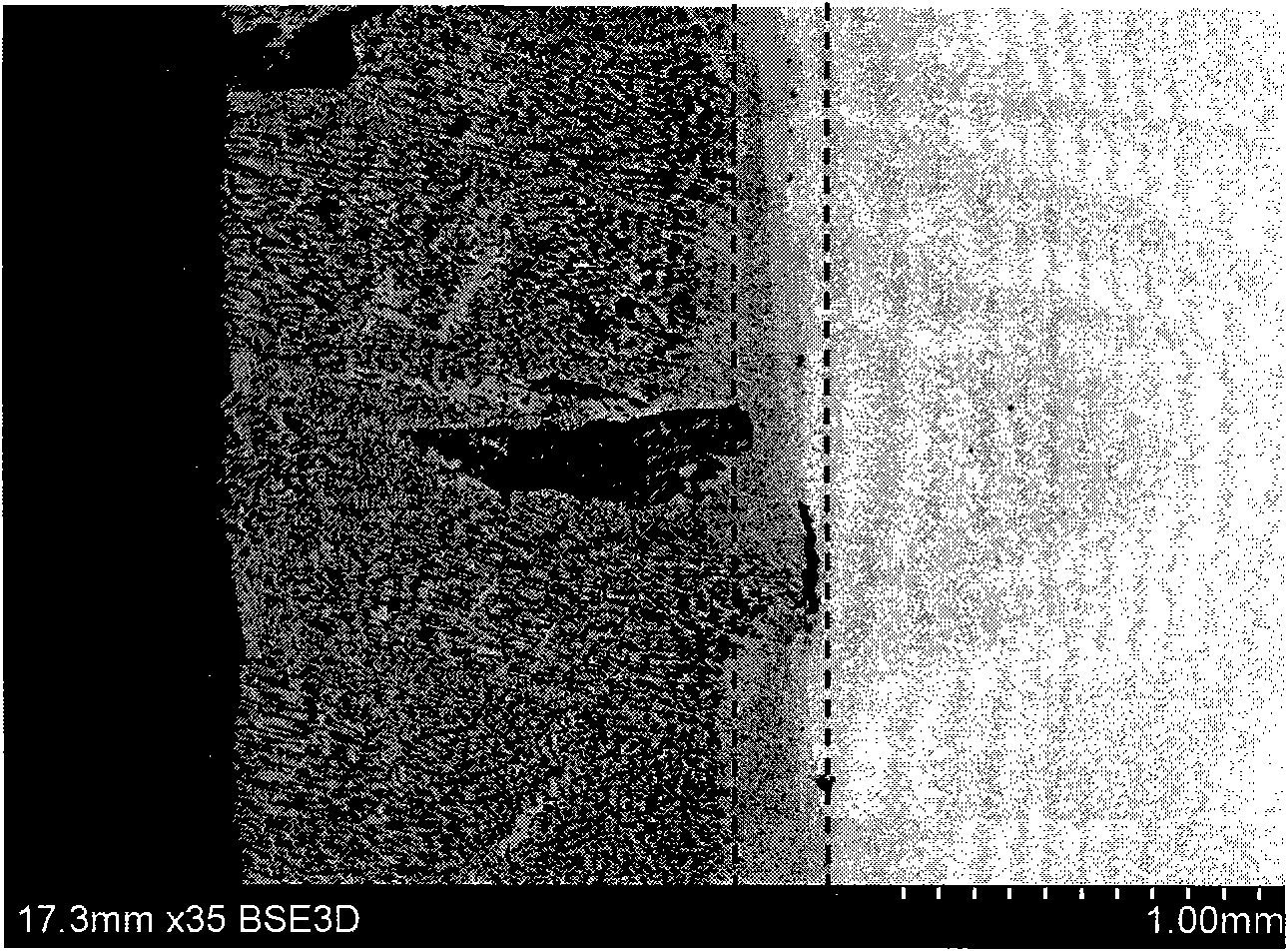

[0024] Using the brazing method described in the specific embodiment one, the scanning electron microscope (SEM) microstructure of the joint obtained by brazing the C / Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature shear strength | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com