Cooling mechanism for axial gap type rotating machines

An axial gap, rotating machine technology, used in synchronous motors with stationary armatures and rotating magnets, cooling/ventilation devices, magnetic circuit shape/style/structure, etc., can solve copper wire breakage, lack of coil holders Cooling mechanism, low thermal conductivity, etc., to achieve the effect of high industrial practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention will be described in detail below in conjunction with the examples. Although an Nd—Fe—B based permanent magnet was described, the present invention is not limited thereto.

[0036] First, a permanent magnet is fabricated through the following steps. Nd is manufactured by melting and casting Nd, Fe, Co and M (M is Al, Si, Cu) each with a purity of 99.7% by weight and B (boron) with a purity of 99.5% by weight in a vacuum furnace 2 Fe 14 B series alloy ingot. The obtained ingot was coarsely pulverized by a jaw crusher, and further subjected to jet mill pulverization in a nitrogen stream to obtain a fine powder with an average particle diameter of 3.5 μm. The obtained fine powder is filled into a mould, and is pressed in a vertical magnetic field of 12kG at 1.0t / cm 2 molding under the molding pressure. In argon, the resulting body was sintered at 1090°C for 1 hour and then heat-treated at 580°C for 1 hour. The shape of the sintered body after he...

Embodiment 1

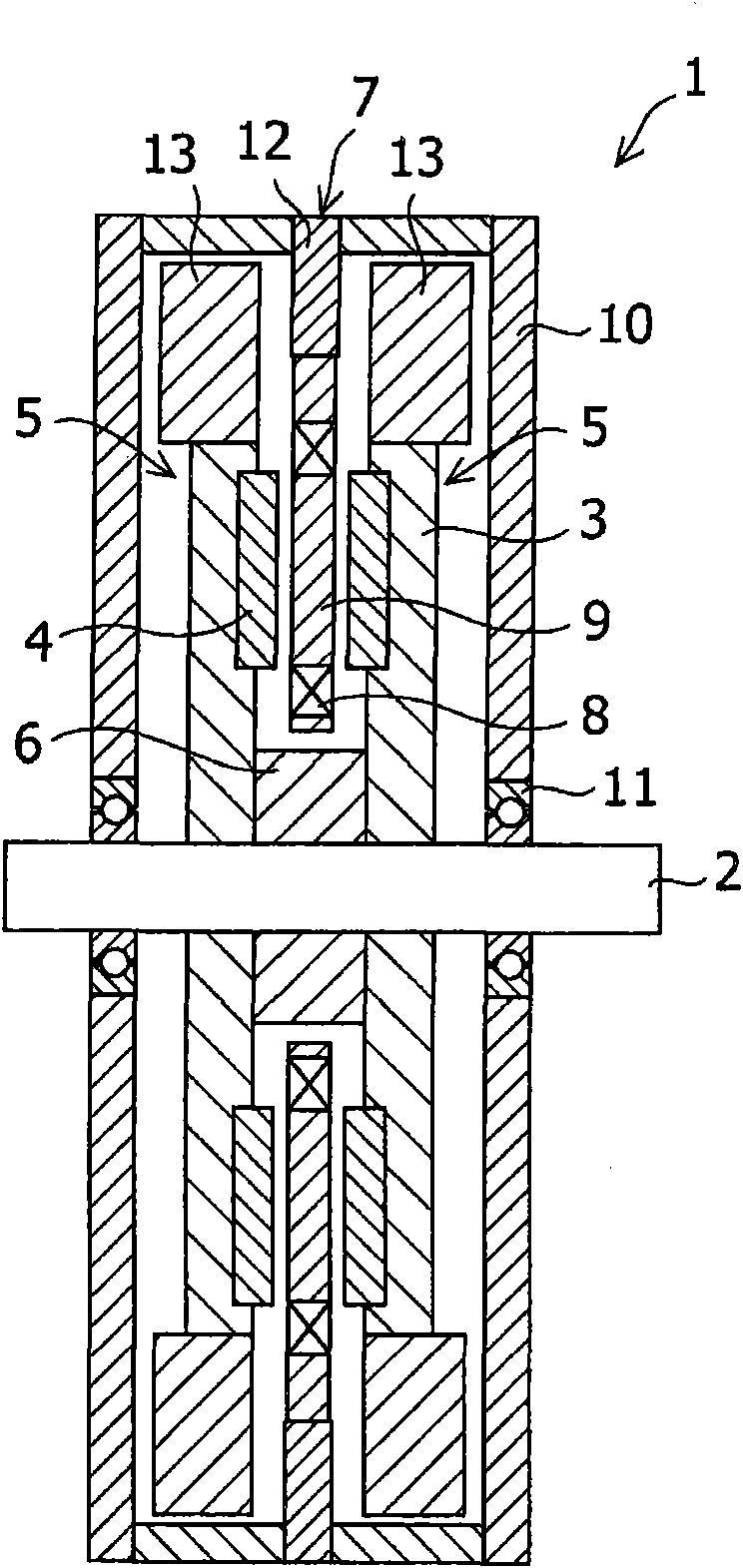

[0040] figure 1 The axial gap type rotary machine used in Example 1 is shown. Its material and size are similar to those of the comparative example, except that the material of the coil holder 9 is changed, a heat radiation fin 12 and a cooling fan 13 are added, and the housing 10 is extended in the radial direction.

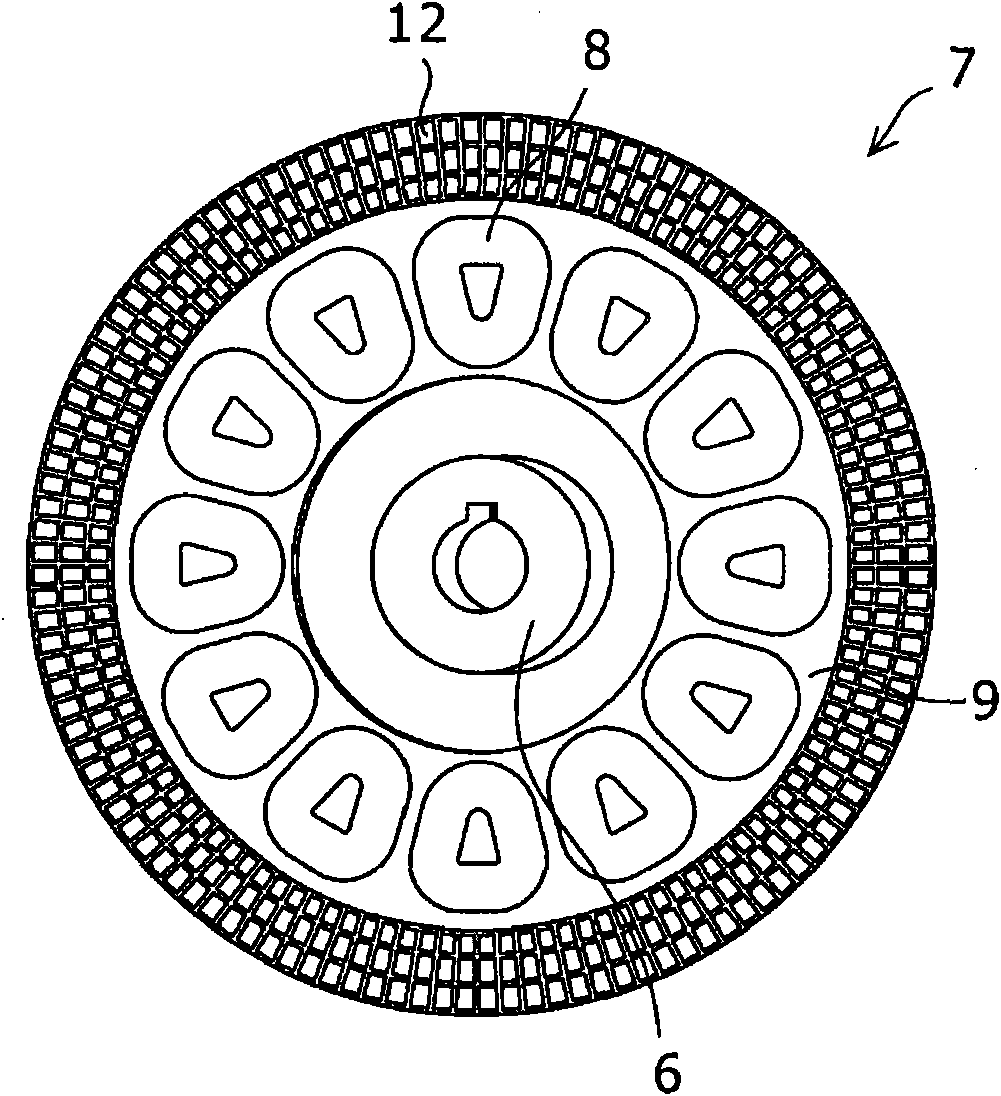

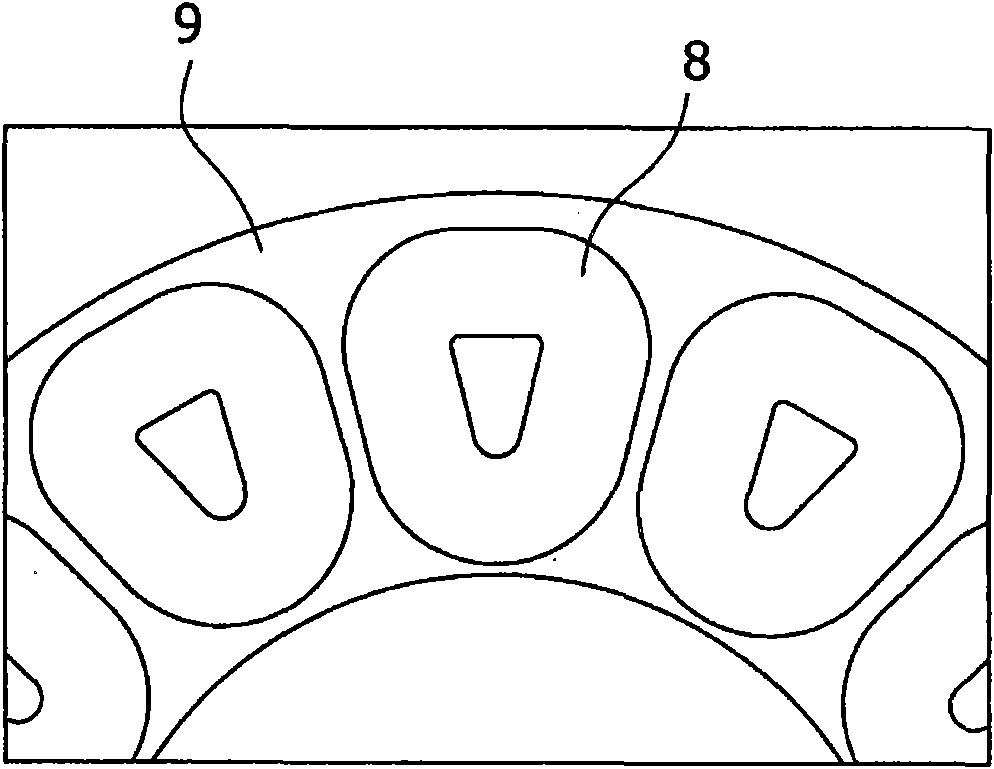

[0041] Coil holder 9 (thermal conductivity is 18W / mK, electrical conductivity is 0.12×10 -13 S / m) is made of thermoplastic resin (liquid crystal polymer) containing inorganic mineral particles composed of alumina. Such as figure 2 As shown, the coil 8 is dipped and formed. The heat radiation sheet 12 is made of aluminum (thermal conductivity 236W / mK), and is formed on its surface with a shape structural feature that increases its surface area by 3 times, thereby effectively applying the cooling effect from the cooling fan 13 to the coil holding Item 9 on. The cooling fans 13 are those manufactured by punching and then bending or welding them. Similar to ...

Embodiment 2

[0043] figure 2 The material of the coil holder 9 was changed, and the same test as in the above-mentioned embodiment 1 was carried out. The test conditions were similar to those when testing Example 1 except that the material of the coil holder 9 was changed. Through this test, the relationship between the thermal conductivity of the coil holder 9 and the coil temperature was obtained. Test results such as Figure 7 and shown in Table 1. Note that since there is no thermal conductivity of 40W / mK (conductivity: 1×10 5 S / m), therefore the test result values are not observations. Use the values obtained from the heat transfer analysis using the finite element method, and add.

[0044] Table 1

[0045] Thermal conductivity of coil holder (W / mK)

[0046] These results indicate that the increase in coil temperature is small when the thermal conductivity is not less than 5 W / mK, that is, good heat release can be secured within the range of thermal conductivity n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com