Allylation hyperbranched polyphenyl ether modified bismaleimide resin and preparation method thereof

A technology of bismaleimide resin and bismaleimide, applied in the field of allylated hyperbranched polyphenylene ether modified bismaleimide resin and its preparation, can solve the unfavorable large-scale industrial Problems such as chemicalization and low product yield, to achieve the effect of excellent manufacturability, abundant raw materials, and outstanding toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

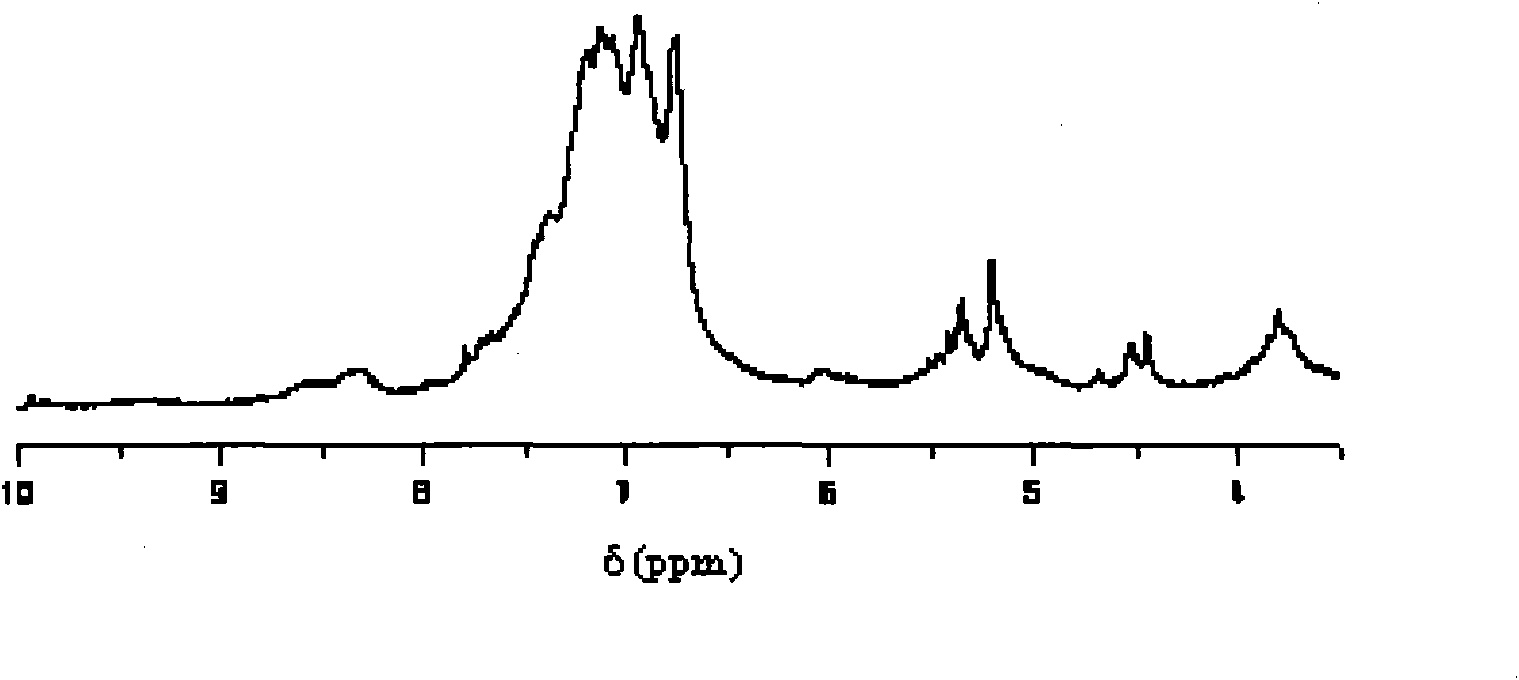

[0020] (1) Preparation of hyperbranched polyphenylene ether

[0021] In a nitrogen atmosphere, 2.41g (6.82mmol) 4-bromo-4',4"-dihydroxytriphenylmethane, 1.08g (7.81mmol) anhydrous K 2 CO 3 And 25.0ml of toluene were added to 98ml of dimethyl sulfoxide (DMSO) successively. After heating and refluxing for dehydration for 3 hours, the reaction system was cooled to 45°C, 13.5mg (0.14mmol) of catalyst CuCl was added, and the temperature was raised to 170°C and kept constant React for 40 hours. After the mixture was cooled to room temperature, it was acidified with hydrochloric acid, and after stirring for 0.5 hours, it was dropped into a solution of methanol and water (volume ratio 1:8) for precipitation, filtered, and dried under vacuum at 60°C. The crude product was dissolved in a small amount of tetrahydrofuran (THF), filtered, the filtrate was precipitated with cyclohexane, then filtered, washed with cyclohexane, and dried under vacuum at 90°C to obtain hyperbranched polyphenylene...

Embodiment 2

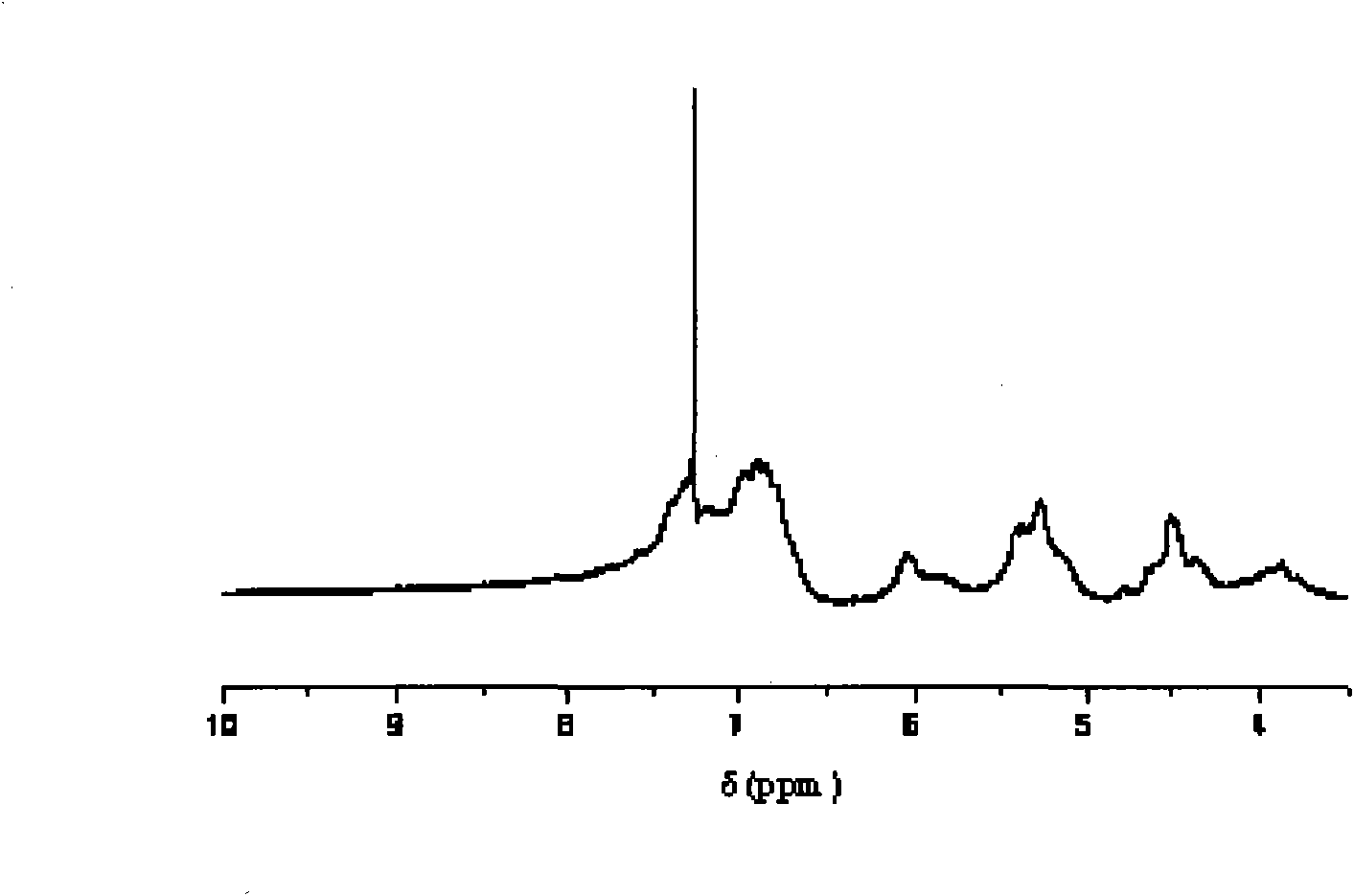

[0032] Preparation of allylated hyperbranched polyphenylene ether

[0033] Under argon atmosphere, at room temperature, 100g of the hyperbranched polyphenylene ether prepared in step (1) of Example 1, 10g of potassium hydroxide, 100g of dimethylformamide (DMF) and 1g of tetrabutyl bromide Ammonium was put into a three-necked flask. The temperature was raised to 70°C and stirred for 1 hour. After the temperature was lowered to 40°C, 10g of 3-bromopropene was added dropwise, and the dropping was completed within 0.5 hours; then the temperature was raised to 60°C, kept refluxed for 3 hours, then 70°C was raised, kept refluxed for 2 hours. After the completion of the reaction, it was cooled to room temperature, stirred and dropped into a solution of methanol and water (volume ratio 1:3), and filtered. After the filter cake was vacuum-dried at 50°C, it was dissolved in tetrahydrofuran, added dropwise to cyclohexane while stirring, filtered, and the filter cake was dried in vacuum at...

Embodiment 3

[0037] Preparation of allylated hyperbranched polyphenylene ether

[0038] Under a nitrogen atmosphere, at room temperature, 100g of the hyperbranched polyphenylene ether prepared in step (1) of Example 1, 1.5g of sodium hydroxide, 150g of dimethylacetamide (DMAc) and 2g of benzyltriethyl chloride The ammonium hydroxide was put into a three-necked flask. The temperature was raised to 60°C and stirred for 0.5 hour. After the temperature was lowered to 50°C, 20 g of 3-chloropropene was added dropwise, and the dropping was completed in 2.5 hours. Then the temperature was raised to 60°C, kept refluxed for 2 hours, and then raised to 80°C, kept refluxed for 2 hours. After the reaction is completed, cool to room temperature, stir and drop into a solution of methanol and water (volume ratio 1:2), and filter. After the filter cake was vacuum-dried at 60°C, it was dissolved in tetrahydrofuran, added dropwise to cyclohexane while stirring, filtered, and the filter cake was dried in vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com