Preparation method for functionalized crosslinked polymer resin microspheres

A cross-linked polymer and resin microsphere technology, which is applied in the field of cross-linked polymer resin preparation, can solve the problems of large-scale production difficulties, high investment cost of functionalized cross-linked polymer resin microspheres, and achieve monodispersity of particle size Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

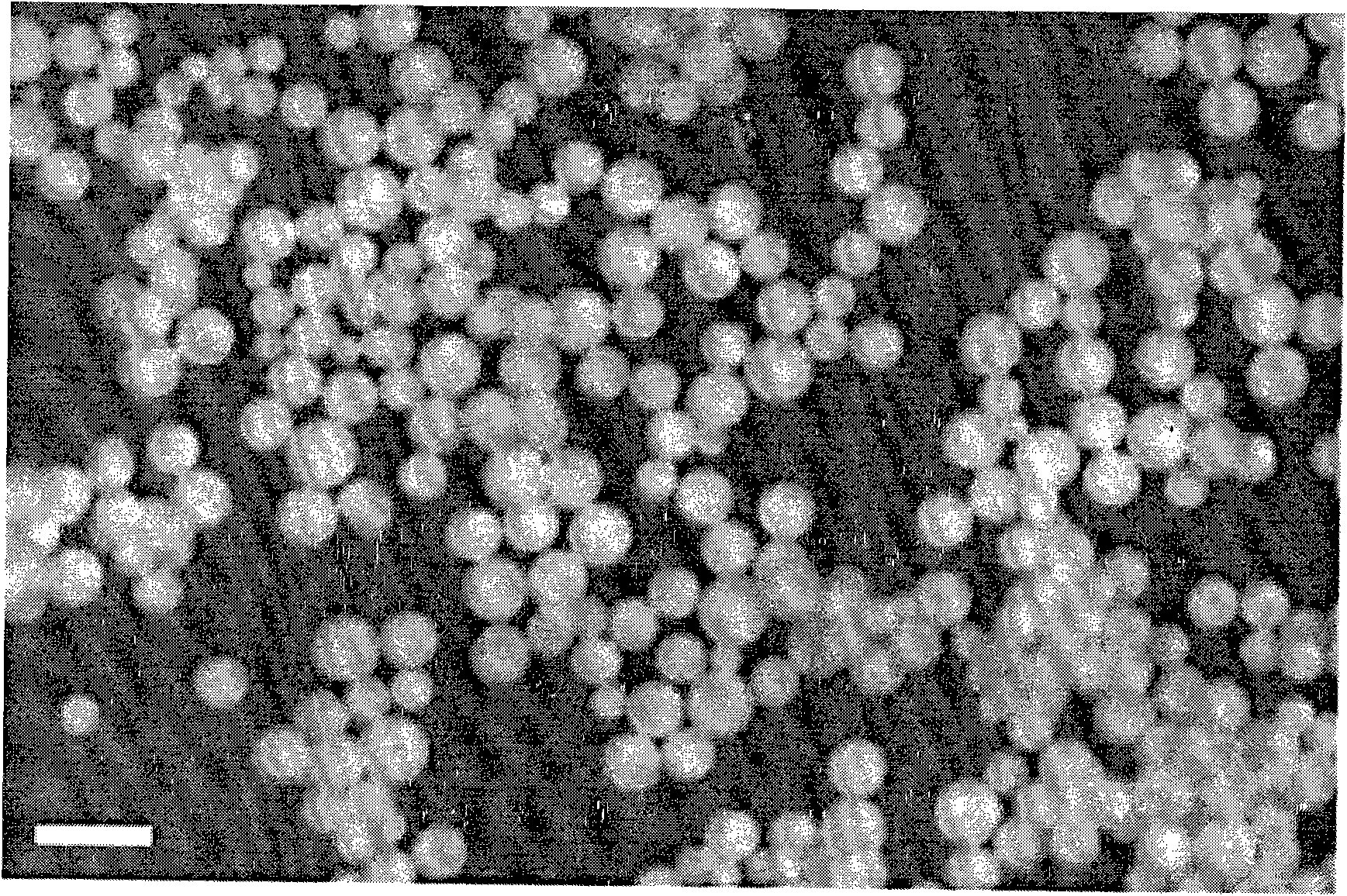

[0032] Add 8 g of styrene, 2 g of divinylbenzene, 0.2 g of benzoyl peroxide, 5 g of isooctane, and 2 g of cis-9-hexadecen-1-ol into 100 g of 1% polyvinyl alcohol in the emulsifier of the aqueous solution. Emulsify at room temperature for 5 minutes at 300 atmospheres, then reduce the pressure to 100 atmospheres and emulsify for another 10 minutes. The emulsified mixed solution was heated to 80°C for polymerization for 6 hours. After the reaction, the polymer product was washed 3 times with 100 milliliters of distilled water, then extracted with acetone for 10 hours in a Soxhlet extractor, and finally vacuum-dried at room temperature to obtain surface-functionalized porous polymer polystyrene microspheres, such as figure 1 As shown, the scale bar in the figure is 200 μm. The resulting microspheres had a particle size of 100 microns, a pore size of 50 nm, and a hydroxyl functionality of 600 micromol / g. figure 2 The pore size and distribution of polystyrene microspheres are sh...

Embodiment 2

[0034] Add 8 g of styrene, 2 g of divinylbenzene, 0.2 g of benzoyl peroxide, 5 g of isooctane, and 1 g of cis-9-hexadecen-1-ol and 1 g of cetyl alcohol to 100 g 1% polyvinyl alcohol solution in an emulsifier. Emulsify at room temperature for 5 minutes at 300 atmospheres, then reduce the pressure to 100 atmospheres and emulsify for another 10 minutes. Then the emulsified mixed solution was heated to 80° C. for 6 hours of polymerization. After the reaction, the polymer product was washed three times with 100 ml of distilled water, then extracted with acetone for 10 hours in a Soxhlet extractor, and finally vacuum-dried at room temperature to obtain surface-functionalized porous polymer polystyrene microspheres. The resulting microspheres had a particle size of 100 microns, a pore size of 50 nm and a hydroxyl functionality of 300 micromol / g. The addition method of divinylbenzene is one-time addition or injection addition in batches.

Embodiment 3

[0036] Add 8 g of styrene, 4 g of divinylbenzene, 0.2 g of benzoyl peroxide, 5 g of isooctane, and 3 g of cis-9-hexadecen-1-ol into 100 g of 1% polyvinyl alcohol in the emulsifier of the aqueous solution. Emulsify at room temperature for 2 minutes at 350 atmospheres, then reduce the pressure to 100 atmospheres and emulsify for another 10 minutes. Then the emulsified mixed solution was heated to 80° C. for 6 hours of polymerization. After the reaction, the polymer product was washed three times with 100 ml of distilled water, then extracted with acetone for 10 hours in a Soxhlet extractor, and finally vacuum-dried at room temperature to obtain surface-functionalized porous polymer polystyrene microspheres. The resulting microspheres had a particle size of 80 microns, a pore size of 50 nm, and a hydroxyl functionality of 900 micromol / g. The addition method of divinylbenzene is one-time addition or injection addition in batches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com