Preparation method of enramycin premix

The technology of enramycin and premix is applied in the field of preparation of enramycin premix, which can solve the problems of high energy consumption, high production cost, complicated process and the like in spray drying, so as to reduce the cost of treatment in the later stage and reduce the production cost. Cost reduction and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

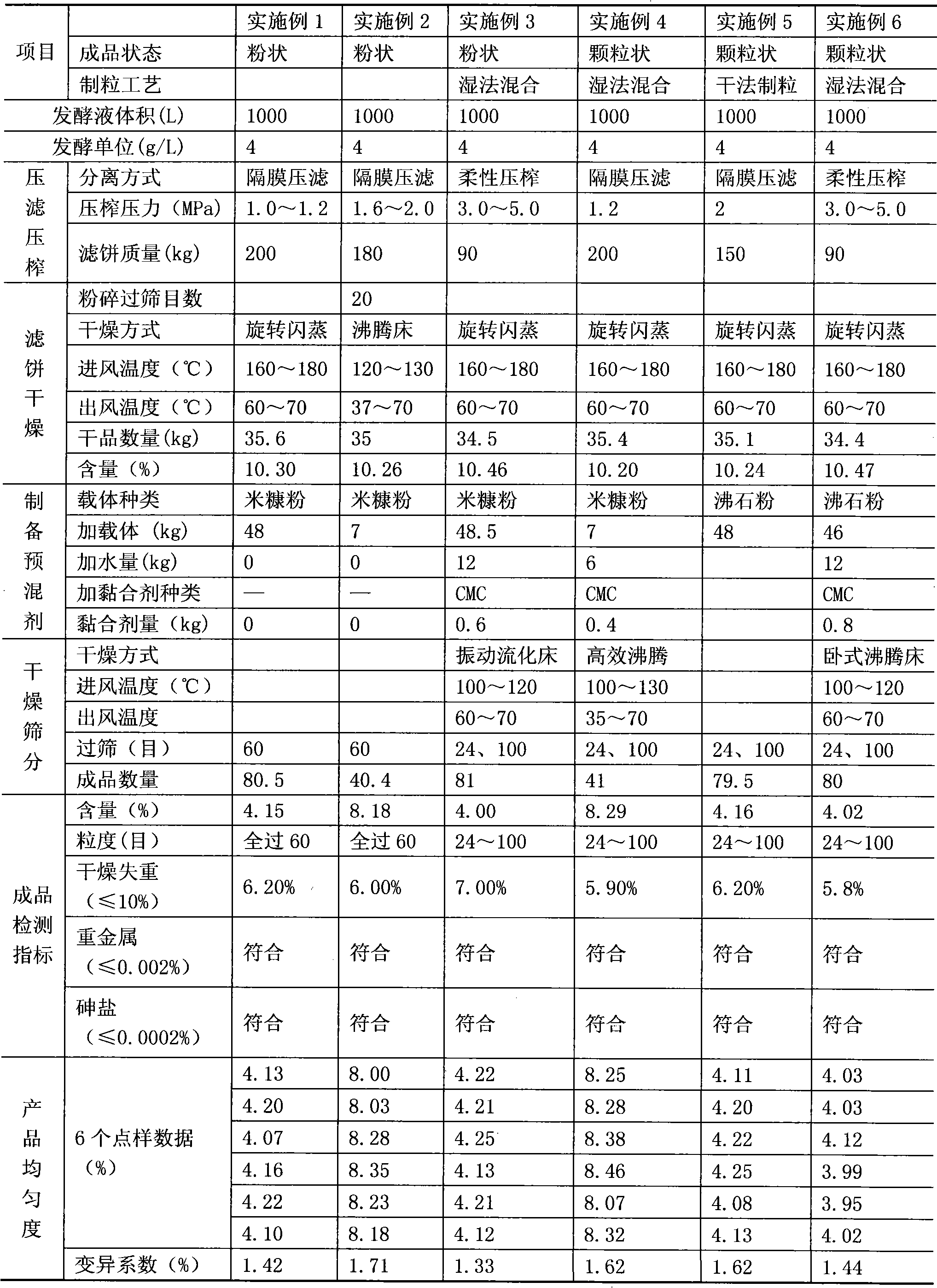

Examples

Embodiment 1

[0024] Embodiment 1 A kind of preparation method of enramycin premix comprises the following steps:

[0025] Fermentation broth preparation Insert the enramycin-producing bacteria into the seed tank, grow for 40-48 hours, connect it to the fermenter at an inoculation rate of 10%, pass air according to the volume ratio of fermentation broth: air = 1: 0.8-1, and ferment The temperature is controlled at 28-30°C, the stirring speed is 120-140 rpm, water is replenished during the fermentation process, and the concentration of the substrate is kept stable, and the culture is carried out for 9-10 days, so that the content of enramycin in each liter of fermentation broth reaches 2-6g; 1000L of ramycin fermented liquid was filtered with a membrane filter press, the pressing pressure was 1.0-1.2MPa, the quality of the filter cake was 200kg, and flash drying was adopted, the inlet air temperature was 160-180°C, and the outlet air temperature was 70-80°C to obtain 35.6 kg dried product, p...

Embodiment 2

[0026] Embodiment 2 A kind of preparation method of enramycin premix comprises the following steps:

[0027] The preparation of the fermentation broth was the same as in Example 1. 1000L of enramycin fermentation broth was filtered by a diaphragm filter press, the maximum pressing pressure was controlled at 1.6-2.0MPa, the water content of the filtered filter cake was 70%, and the number of filter cakes was 180kg. It was dried with a high-efficiency fluidized bed, and the air inlet temperature was 120-200 130° C., the air outlet temperature is 37-70° C., 35 kg of dry product is obtained, crushed, mixed with 7 kg of rice bran powder, and 40.4 kg of 8% powdery enramycin premix is obtained. See Table 1 for the process parameters and quality indicators.

Embodiment 3

[0028] Embodiment 3 A kind of preparation method of enramycin premix comprises the following steps:

[0029] The preparation of the fermentation broth was the same as in Example 1. Squeeze 1000L of enramycin fermentation broth with flexible pressing equipment, control the maximum pressing pressure of 3-5MPa, filter the cake with a water content of 40%, and the number of filter cakes is 90kg, crush it, and use flash drying, and the air inlet temperature is 160-180°C , the air outlet temperature was 60-70° C., and the dried product was pulverized to obtain 34.5 kg of dried product, which was mixed with 48.5 kg of rice bran powder to obtain 80 kg of 4% powdery enramycin premix. See Table 1 for the process parameters and quality indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com