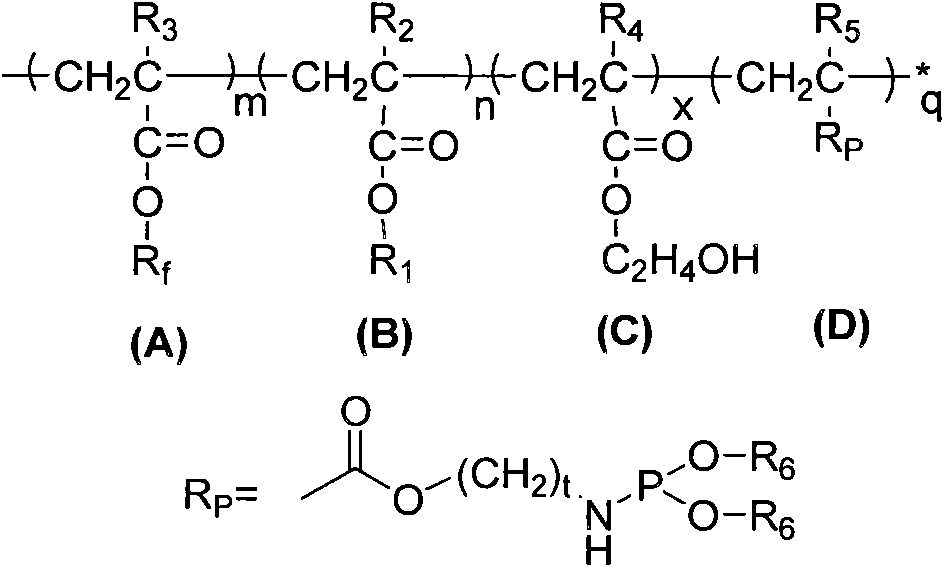

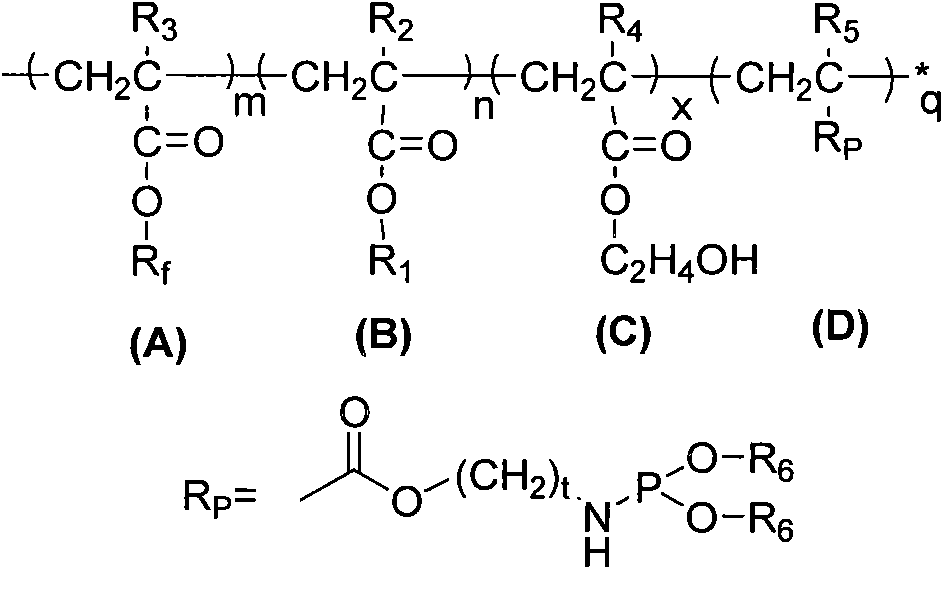

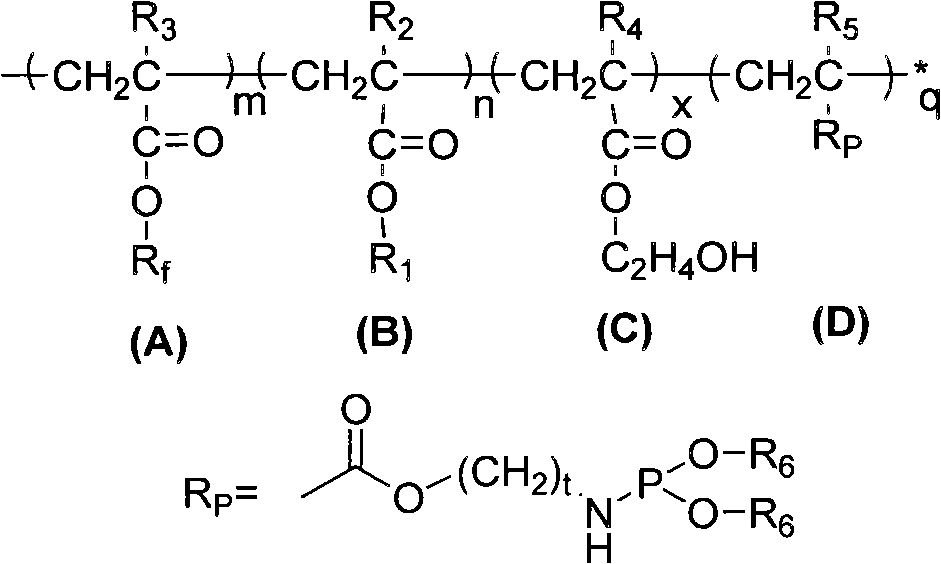

Acrylate polymer integrating water and oil repellence with flame retardancy, and preparation and application thereof

A flame retardant, acrylate technology, used in luminescent materials, textiles and papermaking, fiber processing, etc., can solve the problems of changing fabric properties and differences, and achieve good water and oil repellency and eco-friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add ethanolamine (12.2g, 0.2mol), triethylamine (20.2g, 0.2mol), and 100ml of dichloromethane in a three-necked flask equipped with a constant pressure dropping funnel and a thermometer under the protection of evacuated nitrogen. Slowly add diethyl chlorophosphate (34.4g, 0.2mol) dropwise to the reaction solution at ℃, warm up to room temperature after the dropwise addition, stir for 2h, filter the solid triethylamine hydrochloride, cool the filtrate to a low temperature, and protect it under nitrogen Acryloyl chloride (18.1 g, 0.20 mol) in dichloromethane solution (100 ml) was slowly added dropwise. After the dropwise addition, it was raised to room temperature and stirred overnight. The solid triethylamine hydrochloride was filtered and the solvent was removed to obtain the product. With nuclear magnetic resonance instrument (NMR), Fourier transform infrared spectrometer, gas-mass spectrometer, carry out data analysis and characterize as follows:

[0049]

[0050] ...

Embodiment 2

[0054] In a three-necked flask equipped with a reflux condenser and a thermometer, add acrylic acid (2.4g, 0.0333mol), then add cyclohexane 24mL, 1H, 1H, 2H, 2H-perfluorooctyl alcohol (8.255g, 0.0227mol) ), p-toluenesulfonic acid 0.274g, heated to 80 ° C and refluxed for 8 hours. After the reaction was completed, the product was obtained.

[0055]

[0056] 1 HNMR (400MHz, CDCl 3 ): δ2.57-2.48 (m, 2H), 4.47 (t, J = 12.8Hz, 2H) 5.87 (dd, J = 1.6, 10.8Hz, 1H), 6.13 (dd, J = 10.8, 17.6Hz, 1H ), 6.44 (dd, J=1.6, 17.6Hz, 1H).

[0057] 19 F NMR (376MHz, CDCl 3 ): δ-81.7(t, J=18.4Hz, 3F).-113.99(t, J=16.4Hz, 2F), -122.18(s, 2F), -123.2(s, 2F), -123.9(d, J=12.8Hz, 2F), -126.5(m, 2F),

[0058] IR (thin film, cm -1 ): 2923, 2850, 1735, 1638, 1241.

Embodiment 3

[0060] The above-mentioned fluorine-containing acrylate (0.7g), phosphorus-containing acrylate monomer (4.3g), 2-hydroxyethylacrylamide (0.2g) and octadecyl acrylate (0.5g), sodium lauryl sulfate ( 0.1g) was dissolved in 30mL of deionized water and 3mL of acetone, and then ultrasonic pre-emulsified for 1-5h to obtain a milky white pre-emulsion. in N 2 Under protection, add 1 / 3 of the pre-emulsion to a three-necked flask equipped with a reflux condenser and a thermometer, raise the temperature to 75°C, and slowly add ammonium persulfate aqueous solution (0.015g / 1mL) dropwise to initiate the reaction. When the emulsion shows blue fluorescence Afterwards, stop adding the ammonium persulfate aqueous solution dropwise, combine the remaining initiator and the pre-emulsion (volume ratio is 1:50), slowly add it dropwise into the reaction solution, complete the addition within 2 hours, then continue the reaction at 75°C for 1 hour- Stop reaction after 6h, cool to room temperature to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com