Magnolia biondii pamp volatile oil nanoliposome freeze-dried powder, temperature-sensitive magnolia biondii pamp nanogel and preparation method thereof

A nano-liposome and liposome freeze-drying technology, which is applied in the direction of freeze-drying transportation, pharmaceutical formulations, powder transportation, etc., can solve the problems of lack of systematic and in-depth research, easy volatilization of drugs, application restrictions, etc., and facilitate mass preparation And long-term storage, improve drug efficacy, prolong the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation and performance investigation of nanoliposome freeze-dried powder of magnolia volatile oil

[0054] 1. Instruments and reagents

[0055] 1. Instrument

[0056] Experimental equipment: see Table 1 for details

[0057] Table 1 Experimental Instruments

[0058]

[0059] 2. Reagents

[0060] Experimental raw materials: see Table 2 for details.

[0061] Table 2 Properties and sources of raw materials

[0062]

[0063] 2. Screening of lyoprotectants

[0064] Liquid liposome is a kind of suspension emulsion, which will coagulate, fuse and cause the leakage of the drug contained in it during storage. So freeze-drying protection is very important.

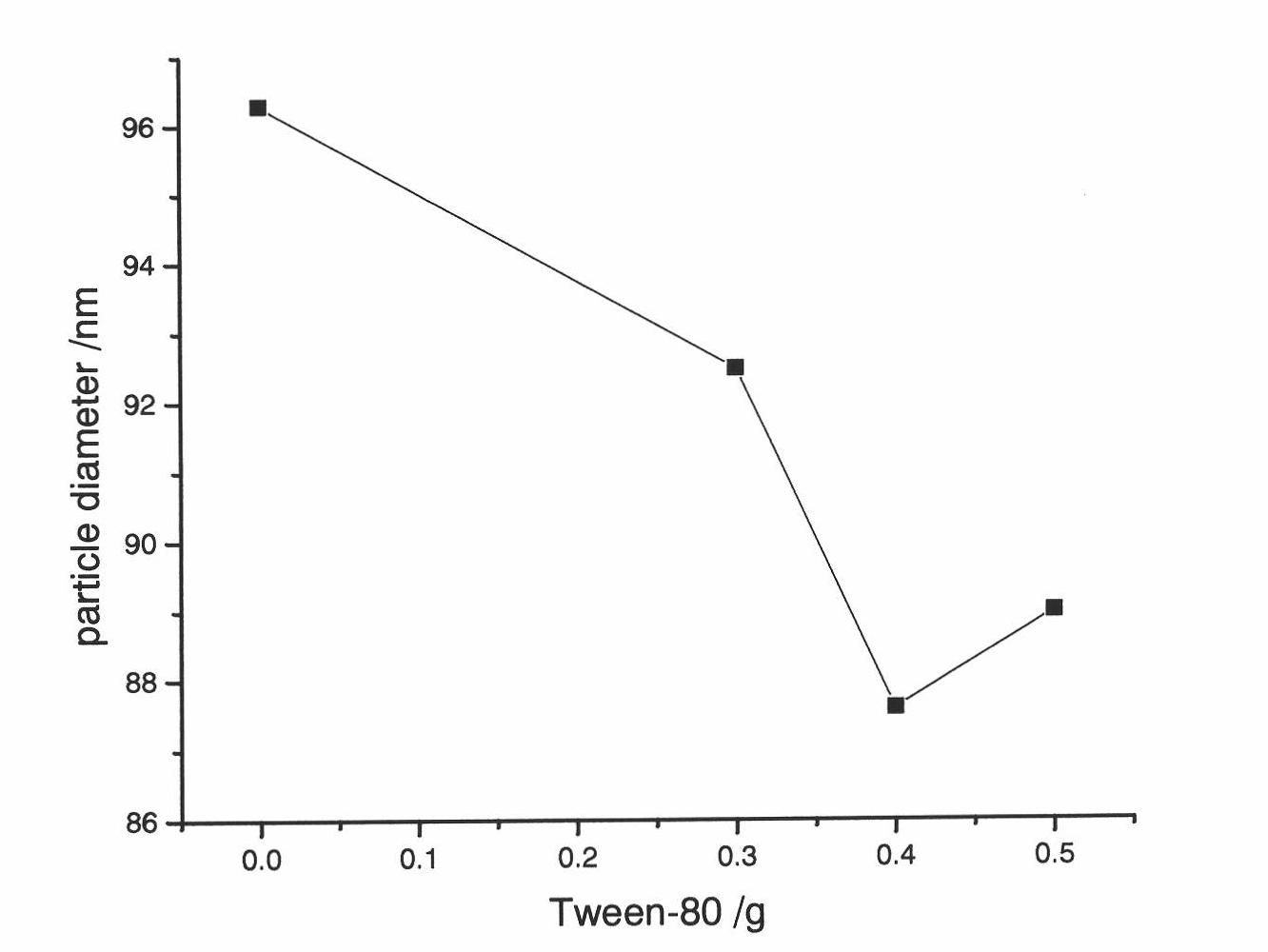

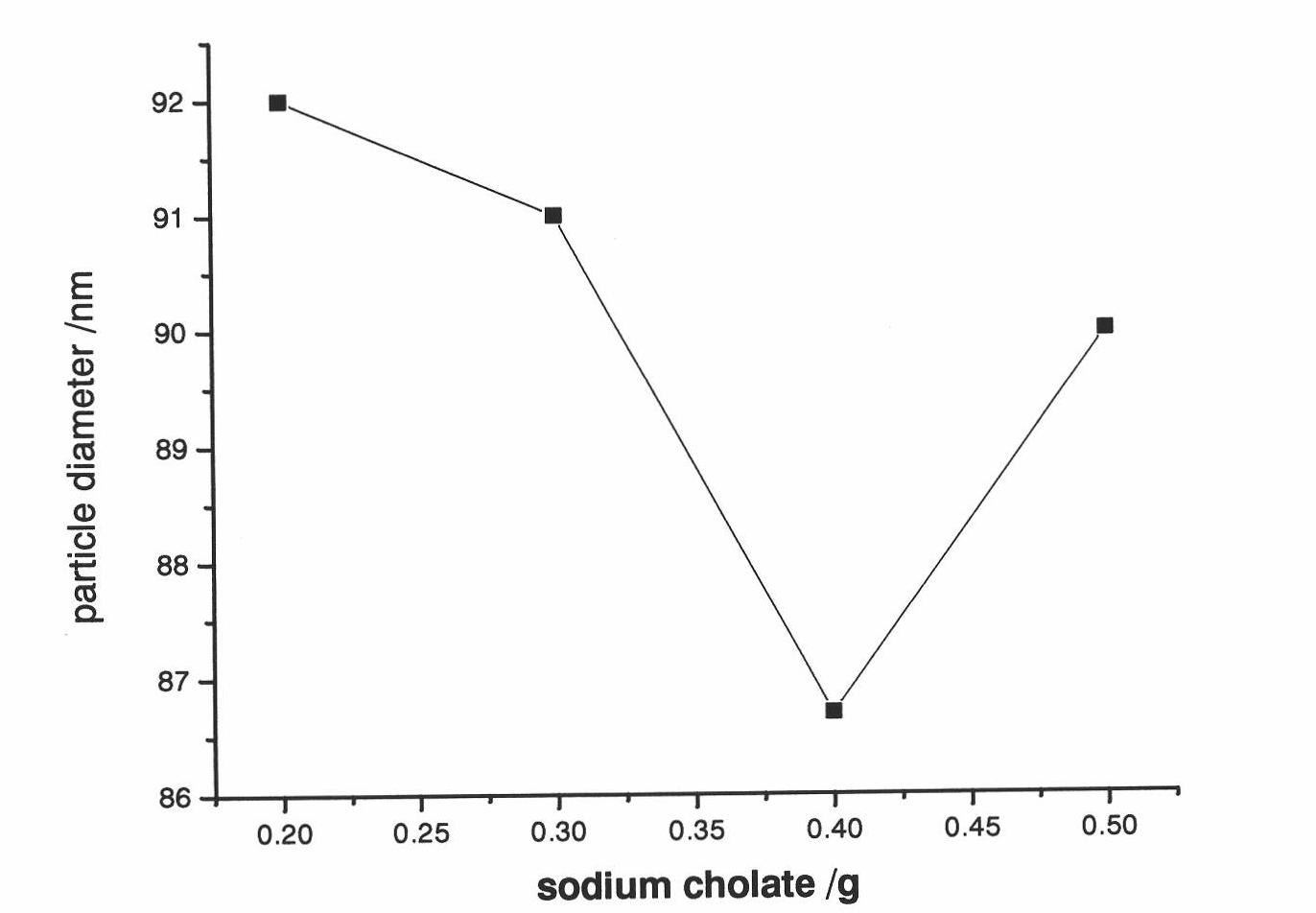

[0065]In order to study the effects of different protective agents and different concentrations of protective agents on the particle size of liposomes during the freeze-drying process, and to find protective agents and their concentrations with better protective effects on liposomes, mannitol, trehalose, and ...

Embodiment 2

[0114] Preparation of temperature-sensitive magnolia nanogel

[0115] For the technical route of preparation of temperature-sensitive magnolia nanogel, see Figure 9

[0116] 1. Preparation of temperature-sensitive dispersion

[0117] Prepare different concentrations of F127 aqueous solution, P188-F127 solution (mixture as shown in Table 4), put it into each centrifuge tube, and put it in an environment of 4°C overnight to fully dissolve it.

[0118] Table 4 P188-F127 ratio

[0119]

[0120] 2. Determination of critical temperature of thermosensitive gel

[0121] (1) Effect of F127 concentration on its own critical temperature

[0122] Fix the centrifuge tube in a constant temperature water tank, let the reagents invade below the liquid surface of the water tank, and raise the temperature with temperature control, 1°C each time, after the temperature stabilizes, last for 10 minutes, then observe whether a gel is formed, and record the temperature at which the gel is for...

Embodiment 3

[0139] In vitro drug release investigation and comparison of temperature-sensitive magnolia nanogel

[0140] 1. In vitro drug release investigation of temperature-sensitive magnolia nanogel

[0141] The drug release in vitro was studied by Franz diffusion cell method. The semi-permeable membrane (molecular weight cut-off 7000u) was fixed between the two pools of the Franz diffusion cell. The area of the Franz diffusion cell used in this experiment was 0.785 cm 2 . Accurately add about 1ml of temperature-sensitive magnolia nanogel into the dosing pool to distribute it evenly on the surface of the semipermeable membrane, and put it in an oven at 33°C for 10 minutes to form a gel. Put the diffusion cell in a 33°C water bath, add 5ml of absolute ethanol that has been preheated to 33°C into the receiving cell as the receiving liquid, put a stirrer in the receiving cell at a speed of 300 rpm, and set the temperature for 5min, 10min, and 20min , 30min, 1h, 2h, 4h, 6h, 8h, 10h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com