Modified polyimide film

A polyimide film and modification technology, which is applied in the field of polyimide films modified by organically treated carbon black, can solve the problems of poor film formation, poor mechanical properties and large shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (2) Preparation of the prepolymer of polyimide:

[0025] Put "dianhydride" monomer, "diamine" monomer and organic solvent in a reactor with stirring device, the molar ratio of "dianhydride" monomer to "diamine" monomer is 1: (1.0~ 1.2), under the condition of 10°C to 30°C, stir for 2 hours to 8 hours to obtain the prepolymer of polyimide;

[0026] (3) Preparation of modified polyimide film:

[0027] The carbon black prepared by step (1) and the prepolymer of polyimide prepared by step (2) are placed in a reactor with a stirring device, stirred and mixed to obtain a mixture, and the content of carbon black in the obtained mixture 0.1wt% to 10wt%, use a threaded coating rod or a spin coater to coat the resulting mixture on a film substrate at a spin coating speed of 500 rpm to 3,500 rpm, and use a gradient temperature rise method under vacuum conditions: That is, keep at 60°C to 110°C for 0.5 hours to 5 hours, at 110°C to 250°C for 0.5 hours to 5 hours, and at 250°C to ...

Embodiment 1

[0036] Chemical modification of carbon black surface

[0037] Carbon black (Mougl-L, produced by Cabot Company) was first heated to reflux (oxidize) with a strong acid solution (98% concentrated sulfuric acid and 69% concentrated nitric acid mixed in a volume ratio of 3:1) for more than 4 hours. Then it was washed with distilled water until neutral, vacuum filtered, and dried to obtain acidified carbon black. Add an appropriate amount of thionyl chloride and dimethylformamide to the acidified carbon black, stir it electromagnetically at 70°C for 24 hours, wash it with tetrahydrofuran, separate it by centrifugation, and dry it in vacuum at room temperature to obtain acid chloride-treated carbon black.

[0038] Utilize the laser particle size analyzer to record the average particle diameter of acid chloride carbon black to be 123nm; To acid chloride carbon black is characterized by infrared spectroscopy, and its result is as follows (KBr): υ (cm -1 ): 3315, 2983, 2758, 1703, 16...

Embodiment 2

[0040] Synthesis of polyimide

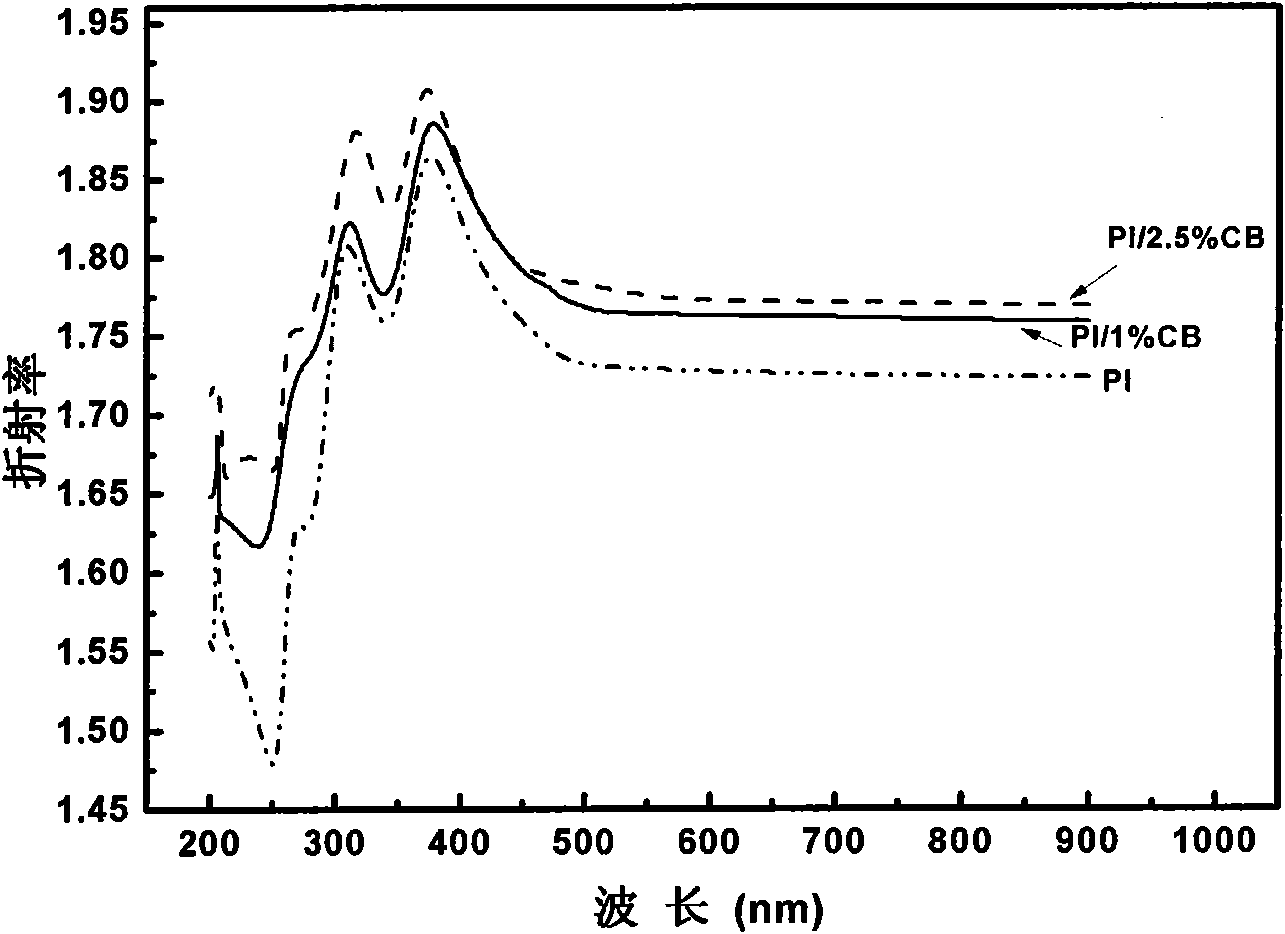

[0041] 1g4,4'-diaminodiphenyl ether (ODA) is added into a three-necked flask, poured into an appropriate amount of dimethylacetamide (DMAc) solvent, fully stirred to fully dissolve ODA in DMAc, and then added biphenyltetracarboxylic dianhydride ( BPDA) 1.5g, that is, the molar ratio of ODA to BPDA is 1:1, stirred at room temperature for 6-8 hours, the resulting polyimide prepolymer - polyamic acid (PAA). On a clean substrate, use a threaded coating rod or a spin coater to coat the film (the spin coating speed is 2000rpm), put it in a vacuum oven, and use the gradient heating imidization method, that is, 100 ° C for 1 hour, 200 ° C for 1 hour , 300° C. for 0.5 hours to convert PAA into a polyimide film (abbreviated as PI), which has a refractive index of 1.727 at 633 nm at room temperature. (see attached figure 1 )

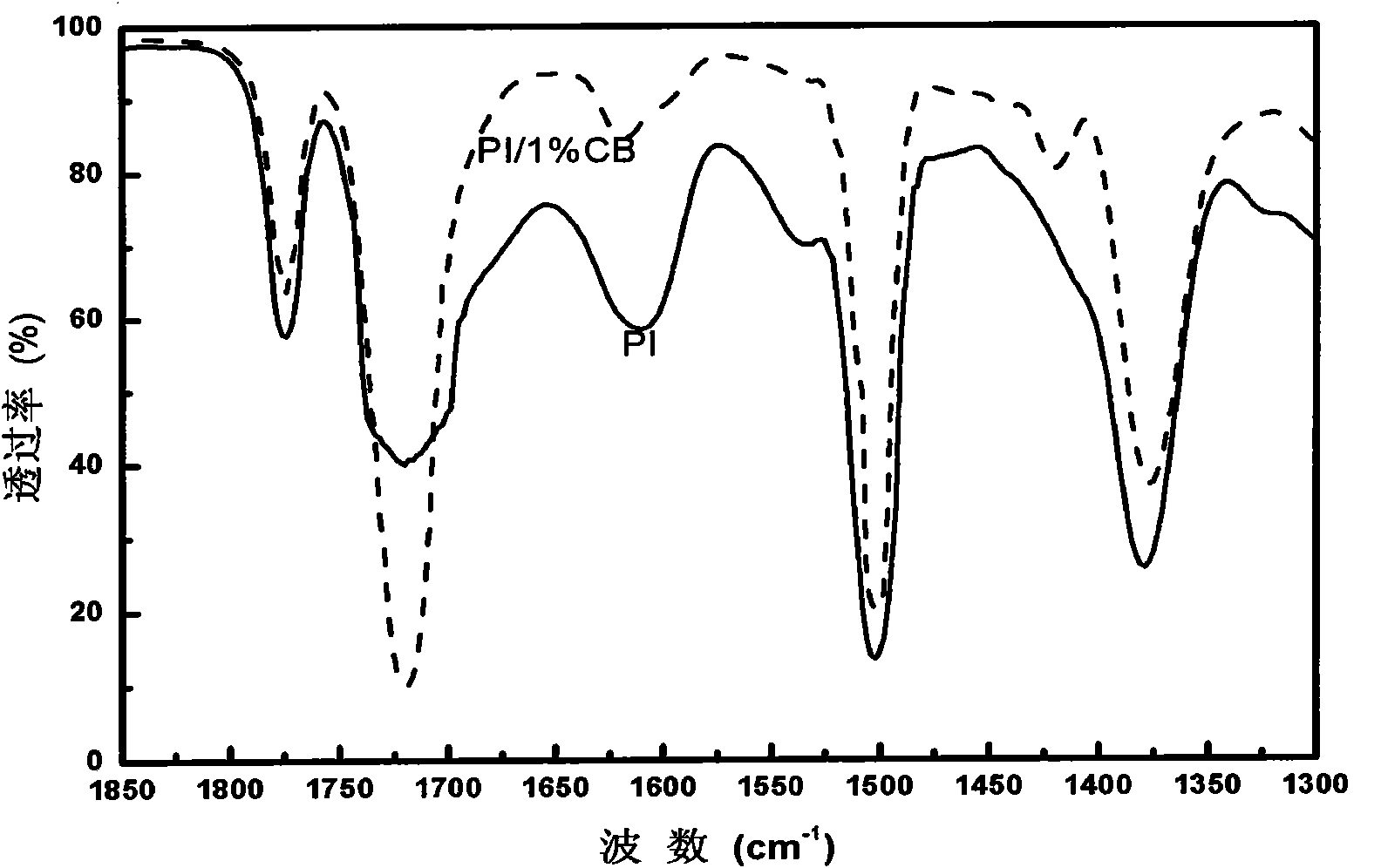

[0042] Infrared spectrum characterization, the results are as follows (KBr): υ(cm -1 ): 3315, 1720, 1605, 1499, 1363, 1204, 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com