Catalyst for catalyzing and oxidizing oxynitride in flue gas and preparation process thereof

A nitrogen oxide, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problem of economical, expensive, ozone consumption Large and other problems, to achieve good denitration effect, improve the degree of oxidation, improve the effect of mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

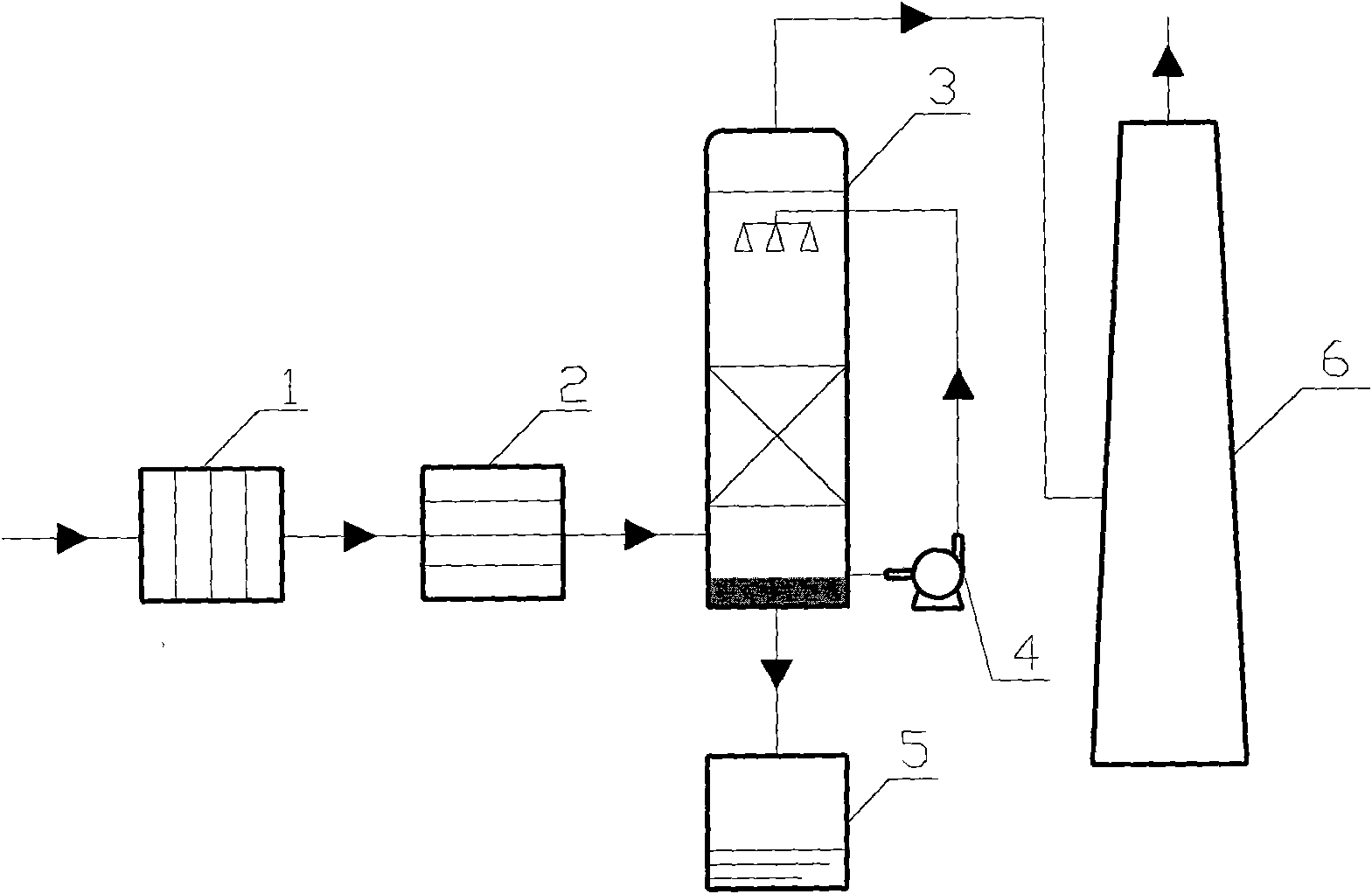

Image

Examples

Embodiment 1

[0034] 1) Preparation of catalyst Pt-K / SiO by equal volume impregnation method 2

[0035] Dry the mesoporous silica in a constant temperature drying oven at 105°C for 8 hours;

[0036] will KNO 3 Prepare solution I with water, immerse the treated mesoporous silica in solution I, soak at room temperature for 12 hours, dry at 105°C for 8 hours in a constant temperature drying oven, and then roast in a muffle furnace at 700°C for 2 hours;

[0037] put H 2 PtCl 6 Prepare solution II with water, and immerse K-loaded mesoporous silica in solution II for 12 hours at room temperature; dry at 105°C for 8 hours in a constant temperature drying oven, and then calcinate at 700°C for 2 hours in a muffle furnace. Finally, it was reduced in hydrogen at 500°C for 2 hours.

[0038] Wherein, the addition of potassium nitrate and chloroplatinic acid is K:Pt:SiO 2 (molar ratio) = 1:0.005:1.

[0039] Finally, the catalyst is obtained by grinding.

[0040] 2) Denitrification process

[004...

Embodiment 2

[0043] 1) Preparation of catalyst Pt-Mo / SiO by equal volume impregnation method 2

[0044] The mesoporous silica was vacuum-dried in a vacuum drying oven at 65°C for 3 hours;

[0045] will (NH 4 ) 6 Mo 7 O 24 The solution I was prepared with water, and the treated mesoporous silica was immersed in the solution I, immersed at room temperature for 12 hours, vacuum-dried at 65°C for 3 hours in a vacuum drying oven, and then calcined at 750°C in a muffle furnace for 2 hours. Hour;

[0046] put H 2 PtCl 6 Mixed with water to form solution II, the Mo-loaded mesoporous silica was immersed in solution II, immersed at room temperature for 12 hours, vacuum-dried at 65°C for 3 hours in a vacuum drying oven, and then calcined at 750°C in a muffle furnace 2 hours and finally reduction in hydrogen at 500°C for 2 hours.

[0047] Wherein, the additions of ammonium heptamolybdate and chloroplatinic acid are Mo:Pt:SiO 2 (molar ratio) = 0.25:0.005:1.

[0048] Finally, the catalyst is ...

Embodiment 3

[0052] 1) Preparation of catalyst Pt-K-Mo / SiO by equal volume impregnation method 2

[0053] The mesoporous silica was vacuum-dried in a vacuum drying oven at 65°C for 3 hours;

[0054] will KNO 3 and (NH 4 ) 6 Mo 7 O 24 Prepare solution I with water, immerse the treated mesoporous silica in solution I, soak at room temperature for 12 hours, vacuum dry at 65°C for 3 hours in a vacuum drying oven, and then calcinate at 700°C in a muffle furnace for 2 hours. Hour;

[0055] put H 2 PtCl 6 The solution II was prepared with water, and the mesoporous silica loaded with K and Mo was immersed in solution II, soaked at room temperature for 12 hours, vacuum-dried at 65°C for 3 hours in a vacuum drying oven, and then immersed in a muffle furnace for 700 ℃. calcined at °C for 2 hours, and finally reduced in hydrogen at 550 °C for 2 hours.

[0056] Wherein, the additions of potassium nitrate, ammonium heptamolybdate and chloroplatinic acid are K:Mo:Pt:SiO 2 (molar ratio) = 1:0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com