Heterogeneous catalytic oxidation method for treating tail gas generated in sodium hypophosphite preparation process from sludge phosphorus

A technology of heterogeneous catalytic oxidation and sodium hypophosphite, applied in hypophosphorous acid, chemical instruments and methods, phosphorous acid, etc., can solve the problems of low absorption efficiency and slow reaction speed, and achieve less catalyst consumption and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

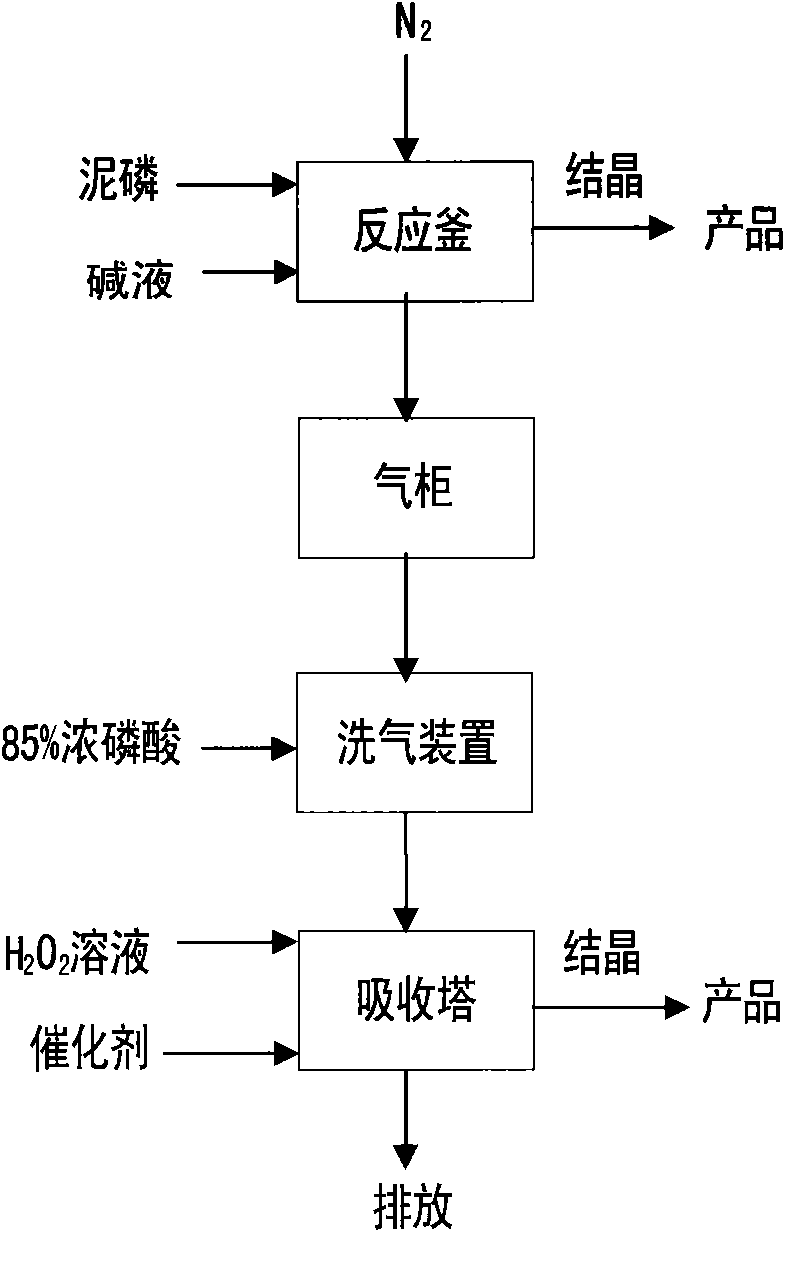

Image

Examples

example 1

[0022] Dissolve cerium nitrate in distilled water to make a solution with a cerium ion concentration of 0.01mol / L; soak activated carbon with a particle size of 40 mesh in 0.1mol / L sodium hydroxide solution for 1 hour, and wash it repeatedly with distilled water after soaking Repeatedly, soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water after soaking, and finally soak in distilled water for 1 hour, filter and dry at 105°C for 12 hours; after pretreatment, according to solid Add liquid mass ratio 1:5 into the prepared solution, stir at room temperature for 4 hours, then soak for 20 hours, and finally filter; put the dried filter cake in a roasting furnace at a roasting temperature of 250°C and keep warm for 2 hour, sieved to obtain a 40-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:100. When preparing sodium hypophosphite, the materials in the reactor are 9.97g of mud phosphorus (...

example 2

[0025] Dissolve ferric nitrate in distilled water to make a solution with an iron ion concentration of 0.5 mol / L; soak 4A zeolite with a particle size of 100 mesh in 0.1 mol / L sodium hydroxide solution for 1 hour, and use distilled water after soaking. Wash for many times, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water after soaking, and finally soak in distilled water for 1 hour, filter and dry at 118°C for 12 hours; after pretreatment, according to Add the solid-liquid mass ratio 1:18 into the prepared solution, stir at room temperature for 5 hours, soak for 19 hours, and finally filter; put the dried filter cake in a roasting furnace at a roasting temperature of 500°C for 4 hours , and sieved to obtain a 100-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:100. When preparing sodium hypophosphite, the materials in the reactor are 9.98g of mud phosphorus (phosphorus conten...

example 3

[0028] Dissolve copper nitrate in distilled water to make a solution with an iron ion concentration of 1mol / L; soak rice husk ash with a particle size of 160 mesh in 0.1mol / L sodium hydroxide solution for 1 hour, and use distilled water after soaking Wash for many times, then soak in 0.1mol / L hydrochloric acid solution for 1 hour, wash repeatedly with distilled water after soaking, and finally soak in distilled water for 1 hour, filter and dry at 130°C for 12 hours; after pretreatment, according to Add solid-liquid mass ratio 1:30 into the prepared solution, stir at room temperature for 6 hours, impregnate for 18 hours, and finally filter; put the dried filter cake in a roasting furnace at a roasting temperature of 800°C and keep it warm for 6 hours , and sieved to obtain a 160-mesh catalyst; the prepared catalyst was added to the hydrogen peroxide solution at a mass ratio of 1:100. When preparing sodium hypophosphite, the materials in the reactor are 10.02g of mud phosphorus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com