LED nitride fluorescent powder and preparation method thereof

A nitride phosphor and chemical structural formula technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of complex process, high cost, and harshness, and achieve the effect of low color temperature, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

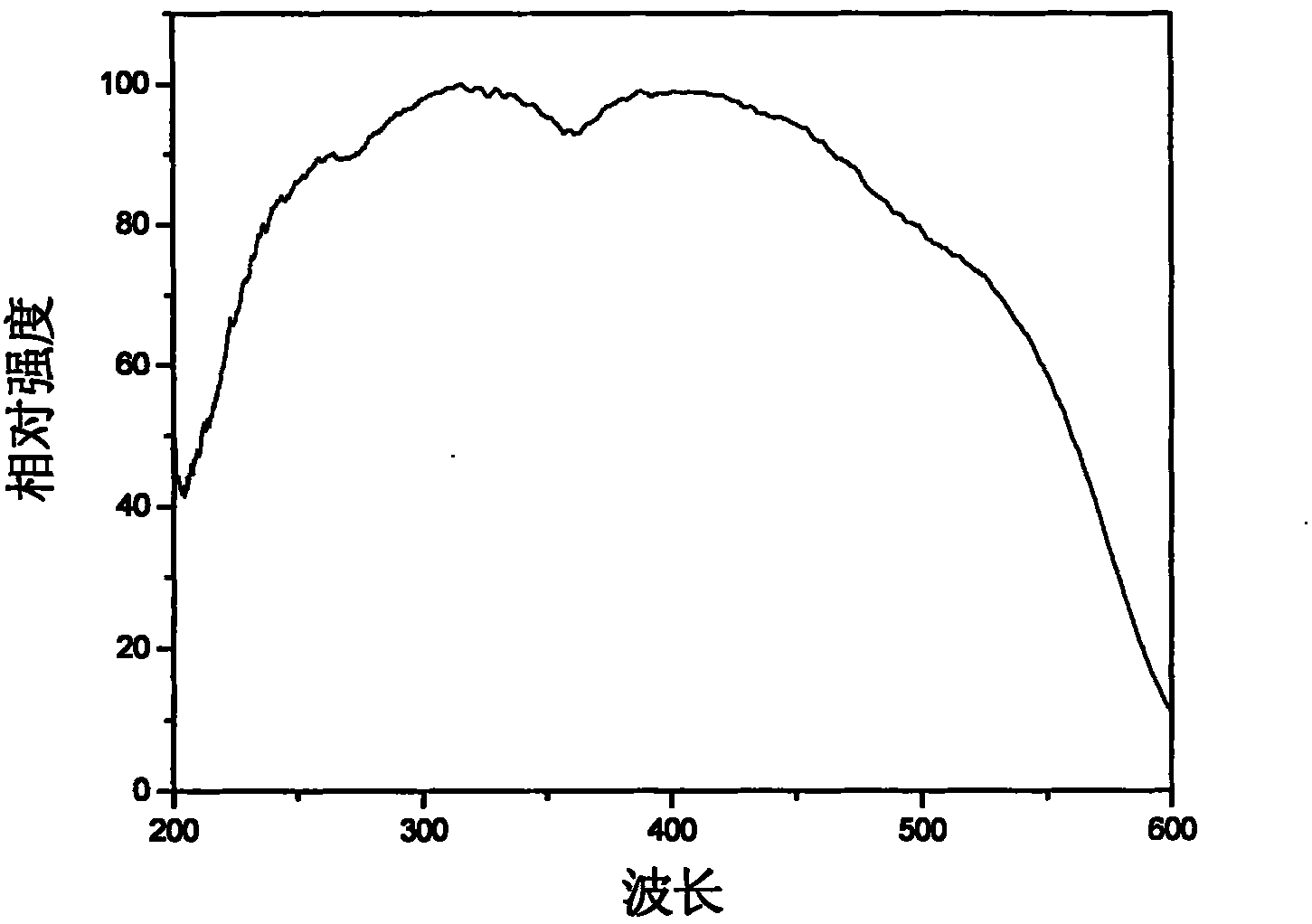

[0036] Weigh Ca 3 N 2 6.771g, Si 3 N 4 6.407g, AlN5.617g, Eu 2 o 3 1.206g, mix the above raw materials in a glove box, put them into a molybdenum crucible, then quickly move them into a tube furnace, then gradually heat up to 1500°C under the protection of a nitrogen-hydrogen mixed atmosphere, and keep warm for 5-7 hours , after cooling down, grind and sieve, then raise the temperature to 1750°C under the protection of a nitrogen-hydrogen mixed atmosphere, keep warm for 8-10h, after grinding and sieving, wash with 10% nitric acid, and finally wash with deionized water, Drying can produce Ca 0.95 AlSiN 3 : 0.05Eu nitride phosphor. Its excitation spectrum see figure 1 , the monitoring wavelength is 660nm, from figure 1 It can be seen from the above that the excitation peak of the excitation spectrum is relatively broad, and the excitation effects in the violet, ultraviolet and blue light ranges are very good. Its emission spectrum see figure 2 , the excitation wavele...

Embodiment 2

[0038] Weigh Ca 3 N 2 6.602g, Si 3 N 4 6.247g, AlN5.477g, Eu 2 o 3 1.175g, Dy 2 o 3 0.498g, mix the above raw materials well in a glove box, put them into a molybdenum crucible, then quickly move them into a tube furnace, then gradually raise the temperature to 1500°C under the protection of a nitrogen-hydrogen mixed atmosphere, and keep it warm for 5-7 hours , after cooling down, grind and sieve, then raise the temperature to 1750°C under the protection of nitrogen-hydrogen mixed atmosphere, keep warm for 8-10h, after grinding and sieving, wash with 5% hydrochloric acid, and finally wash with deionized water, Drying can produce Ca 0.93 AlSiN 3 : 0.05Eu, 0.02Dy nitride phosphor. The emission main peak and luminous intensity are shown in Table 1, both of which are higher than those of Comparative Example 1.

Embodiment 3

[0040] Weigh Ca 3 N 2 6.445,Si 3 N 4 6.099g, AlN5.079g, GaN0.546g, Eu 2 o 3 1.148g, Sm 2 o 3 0.682g, the above raw materials are fully mixed in a glove box, put into a molybdenum crucible, and then quickly moved into a tube furnace, and then gradually heated up to 1500°C under the protection of high-purity nitrogen, and kept for 5-7 hours. After cooling down, grind and sieve, then raise the temperature to 1750°C under the protection of high-purity nitrogen, keep warm for 8-10h, after grinding and sieving, wash with 8% phosphoric acid, and finally wash with deionized water and dry , to produce Ca 0.92 al 0.95 Ga 0.05 SiN 3 : 0.05Eu, 0.03Sm nitride phosphor. The emission main peak and luminous intensity are shown in Table 1, both of which are higher than those of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com