Siliceous LED fluorescent powder and manufacturing method and produced luminescent device

一种制造方法、发光器件的技术,应用在发光材料、半导体器件、化学仪器和方法等方向,达到制造方法简单可行、性能稳定、提高发光效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

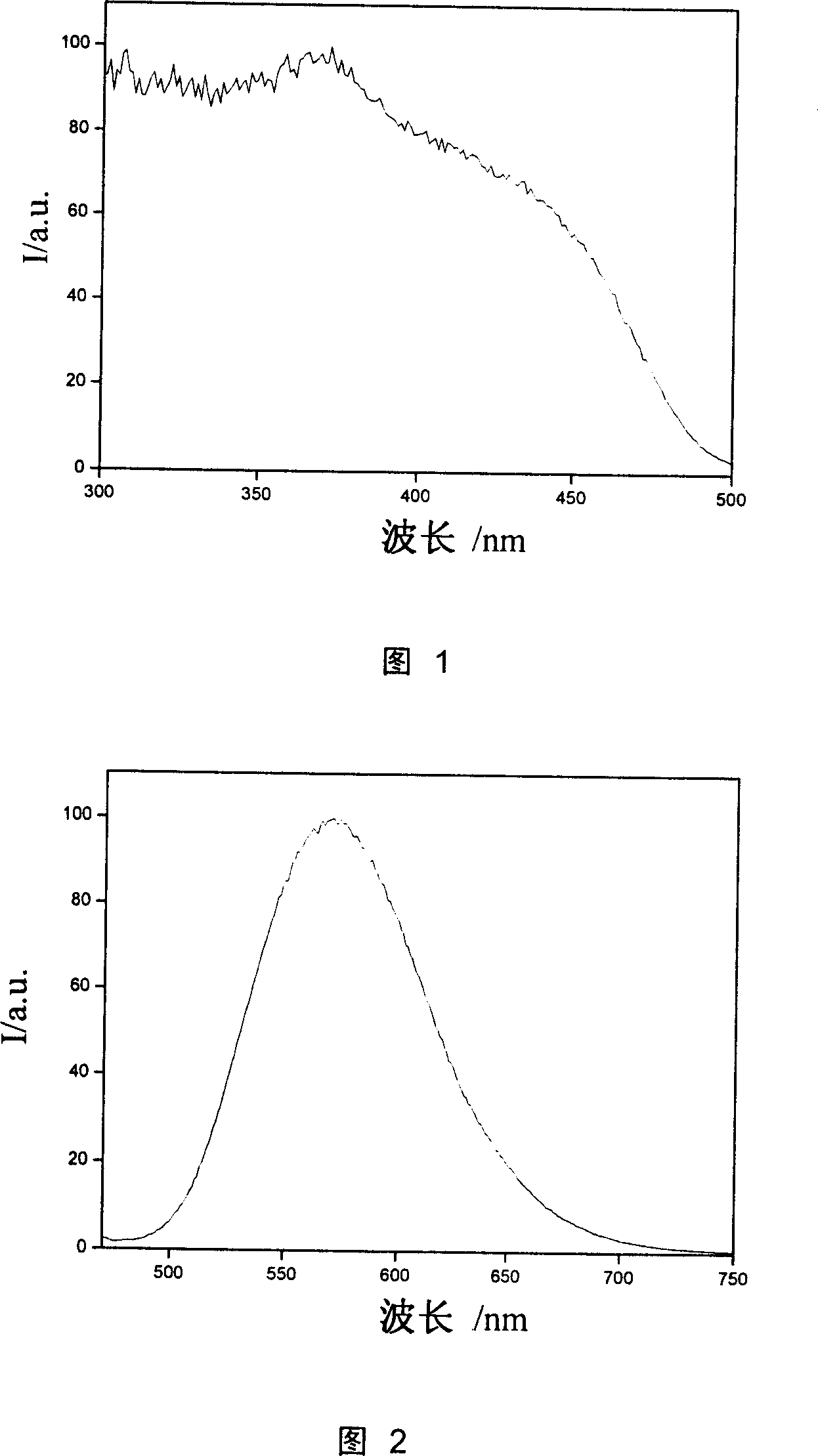

[0046] Example 1: BaCO 3 0.315g, SrCO 3 11.546g, SiO 2 2.398g, Eu 2 o 3 0.421g, MgF 2 0.050g, Y 2 o 3 The manufacturing method of 0.270 g is the same as that of the comparative example. The chemical formula is obtained as (Sr 0.98 Ba 0.02 )O 0.5SiO 2 0.01MgF 2 :0.03Eu 2+ , 0.03Y 3+ of fluorescent powder. Its excitation and emission spectra are shown in Figures 1 and 2. It can be seen that the excitation peak of the excitation spectrum is relatively wide, and the excitation effect of light with a wavelength in the range of 300nm-470nm is better, so it is suitable for ultraviolet light, purple light or blue light LED chips and the like. Its main emission peak is at 570nm, and its emission intensity is compared as shown in Table 1. It can be seen that the emission intensity increases significantly after adding Y.

Embodiment 2

[0047] Embodiment 2: take by weighing CaCO 3 0.155g, SrCO 3 11.177g, SiO 2 2.321g, Eu 2 o 3 0.544g, BaF 2 0.203g, Y 2 o 3 0.349g, La 2 o 3 The manufacturing method of 0.252g is the same as that of the comparative example. The chemical formula is obtained as: (Sr 0.98 Ca 0.02 )O 0.5SiO 2 0.015BaF 2 :0.04Eu 2+ , 0.04Y 3+ , 0.02La 3+ Its luminous intensity and emission main peak are shown in Table 1.

Embodiment 3- Embodiment 50

[0049] Except for weighing the raw materials according to the chemical formula composition and stoichiometry of each embodiment in Table 1, the rest of the manufacturing steps are the same as in Example 1, and the chemical composition, emission main peak and relative luminous intensity are shown in Table 1.

[0050] The chemical formula of table 1 embodiment 1-50 and comparative example and its relative luminous intensity

[0051] Example

[0052] 11

[0053] 27

[0054] 42

[0055] It can be seen from Table 1 that from Example 1 to Example 50, the luminous intensity of the phosphor powder after co-doping is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com