Bullet-resistant glass and fireproof glass for insulating heat and resisting radiation, as well as compound glass thereof

A bulletproof glass, fireproof glass technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of glass bonding strength, hardening of plasticizers, inability to absorb, etc. , to prevent damage to the optic nerve, prevent rain and dew atomization, and prevent accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Preparation of laminated safety glass

[0048] Weigh each component of the organic interlayer adhesive material according to the following weight percentages:

[0049] Main material 60.0%~70.0%; Modifier 10.0%~15.0%; Modifier 3.0%~5.0%;

[0050] Crosslinking agent 0.1% ~ 1.5%; coupling agent 0.5% ~ 1.5%; thickener 1.0% ~ 3.0%;

[0051] Photoinitiator 0.5%~2.5%; Catalyst 1.0%~5.0%; Anti-impact agent 3.0%~5.0%;

[0052] Excipient 0.5%~2.0%; UV-IR optical protection material 0.5%~5%.

[0053] Among them, the main material is methyl methacrylate; the modifier is selected from methacrylic acid, n-butyl methacrylate, n-butyl acrylate or a mixture of two or more; the modifier is selected from hydroxypropyl acrylate One or two mixtures of esters and hydroxypropyl methacrylate; the crosslinking agent is selected from one or two mixtures of glycidyl methacrylate and allyl methacrylate; the coupling agent is selected from A mixture of one or two of self-coupling ...

Embodiment 2

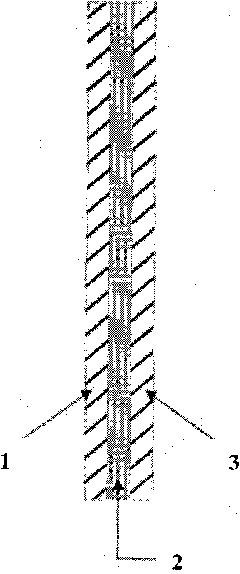

[0057] Embodiment two: the preparation of bulletproof glass

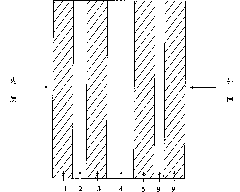

[0058] Take three pieces of silicate glass with a thickness of 2 mm to 5 mm, wash and dry them; make a mold frame according to the method described in Example 1, wherein, from the inside to the outside, the first interlayer is an organic interlayer adhesive material layer, and its The filling thickness is controlled at 0.5 mm to 3 mm; the second interlayer is a bulletproof rubber layer, and its filling thickness is controlled at 3 mm to 8 mm.

[0059] The organic interlayer adhesive material prepolymerized slurry was prepared according to the method described in Example 1.

[0060] Weigh each component of bulletproof rubber according to the following weight percentages, and carry out pre-polymerization pulping:

[0061] n-butyl methacrylate 65.0%~70.0%; fluorene 10.0%~12.0%;

[0062] Butyl acrylate 8.0%~10.0%; vinyl siloxane coupling agent 3.0%~5.0%;

[0063] Vinyl acetate 2.0%~3.0%; Lithium thphenoyltrioxydiacet...

Embodiment 3

[0069] Embodiment three: preparation of fireproof glass

[0070] Get two pieces of silicate glass with a thickness of 2 mm to 5 mm and a piece of cesium potassium glass with a thickness of 3 mm to 5 mm, wash and dry; make a mold frame according to the method described in Example 1, wherein the cesium potassium glass is arranged on the outermost Layers; from inside to outside, the first interlayer is an organic interlayer adhesive material layer, and its filling thickness is controlled at 0.5mm-3mm; the second interlayer is a flame-retardant adhesive layer, and its filling thickness is controlled at 2mm-4mm.

[0071] The organic interlayer adhesive material prepolymerized slurry was prepared according to the method described in Example 1.

[0072] Weigh each component of the flame-retardant rubber according to the following weight percentages for pre-polymerization pulping:

[0073] Vinyl bromide 25.0%~30.0%; Halogenated polyphosphate 18.0%~20.0%;

[0074]Methyl methacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com