Composition for resist lower layer film formation for lithography and process for producing semiconductor device

一种抗蚀剂下层、组合物的技术,应用在半导体/固态器件制造、图纹面的照相制版工艺、用于光机械设备的光敏材料等方向,能够解决没有记载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

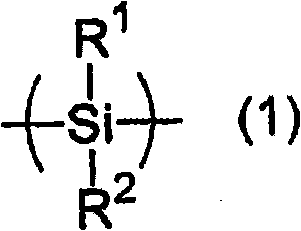

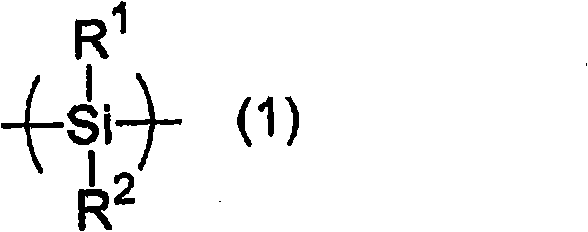

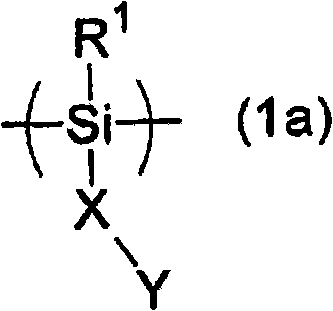

Method used

Image

Examples

Synthetic example 1

[0066] Prepare a toluene solution containing a concentration of 10% by mass of the following compound having structural units represented by the following formula (6a) and formula (7a) and having a silanol group, a hydrogen atom, and a chlorine atom at the end. Polysilane compound (manufactured by Osaka Gas Chemical Co., Ltd., brand name SI-2030, weight average molecular weight 2200, number average molecular weight 1400).

[0067]

[0068] The chlorine atom at the terminal is an impurity derived from the raw material for synthesizing the polysilane. 2.04 g of 1-adamantanol (manufactured by Tokyo Chemical Industry Co., Ltd.) and 0.40 g of nickel chloride were added to 20.00 g of this toluene solution, and stirred at room temperature for 17 hours. Then nickel chloride was removed by filtration, the solvent (toluene) was distilled off under reduced pressure, and vacuum-dried at 80° C. for 10 hours. Yield 2.36 g. The amount of adamantane ring introduced into the obtained poly...

Synthetic example 2

[0070] Add α- 1.37 g of hydroxy-γ-butyrolactone and 0.34 g of nickel chloride were stirred at room temperature for 17 hours. Then nickel chloride was removed by filtration, the solvent (toluene) was distilled off under reduced pressure, and vacuum-dried at 80° C. for 10 hours. Yield 2.48g. The amount of 5-membered ring lactone introduced into the obtained polymer was 19% by mass relative to 100% by mass of the raw material polysilane compound before reacting with α-hydroxy-γ-butyrolactone.

Embodiment 1

[0072] To 0.40 g of the polymer obtained in Synthesis Example 1, 9.60 g of propylene glycol monomethyl ether acetate was added to obtain a 4.0% by mass solution. Then, it was filtered using a polyethylene microfilter with a pore size of 0.1 μm to prepare a solution as a composition for forming a resist underlayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com