MCrAlY coating with excellent oxidation resistance and preparation method thereof

A technology of anti-oxidation performance and coating, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of high cost, large porosity, complex process, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

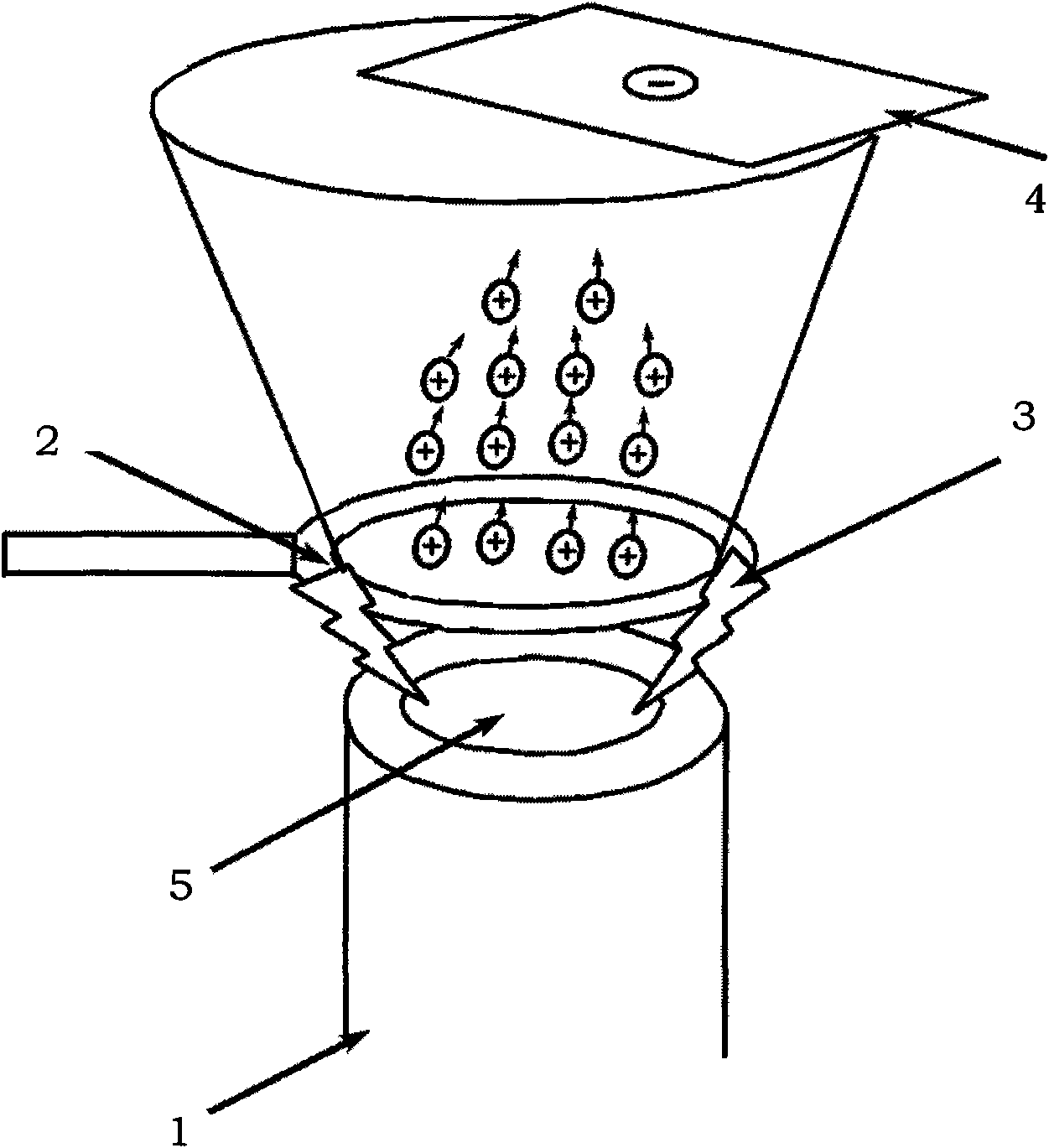

Method used

Image

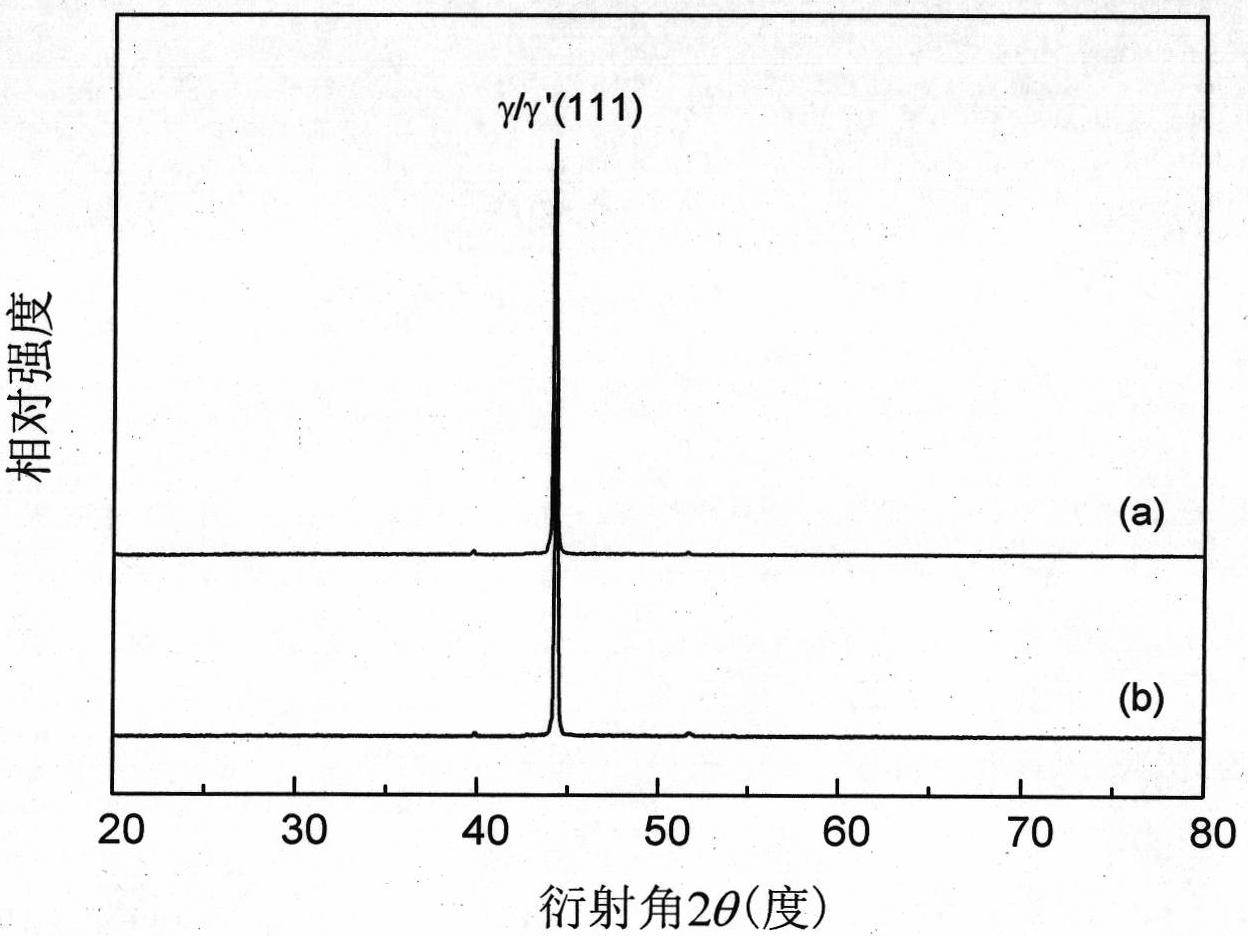

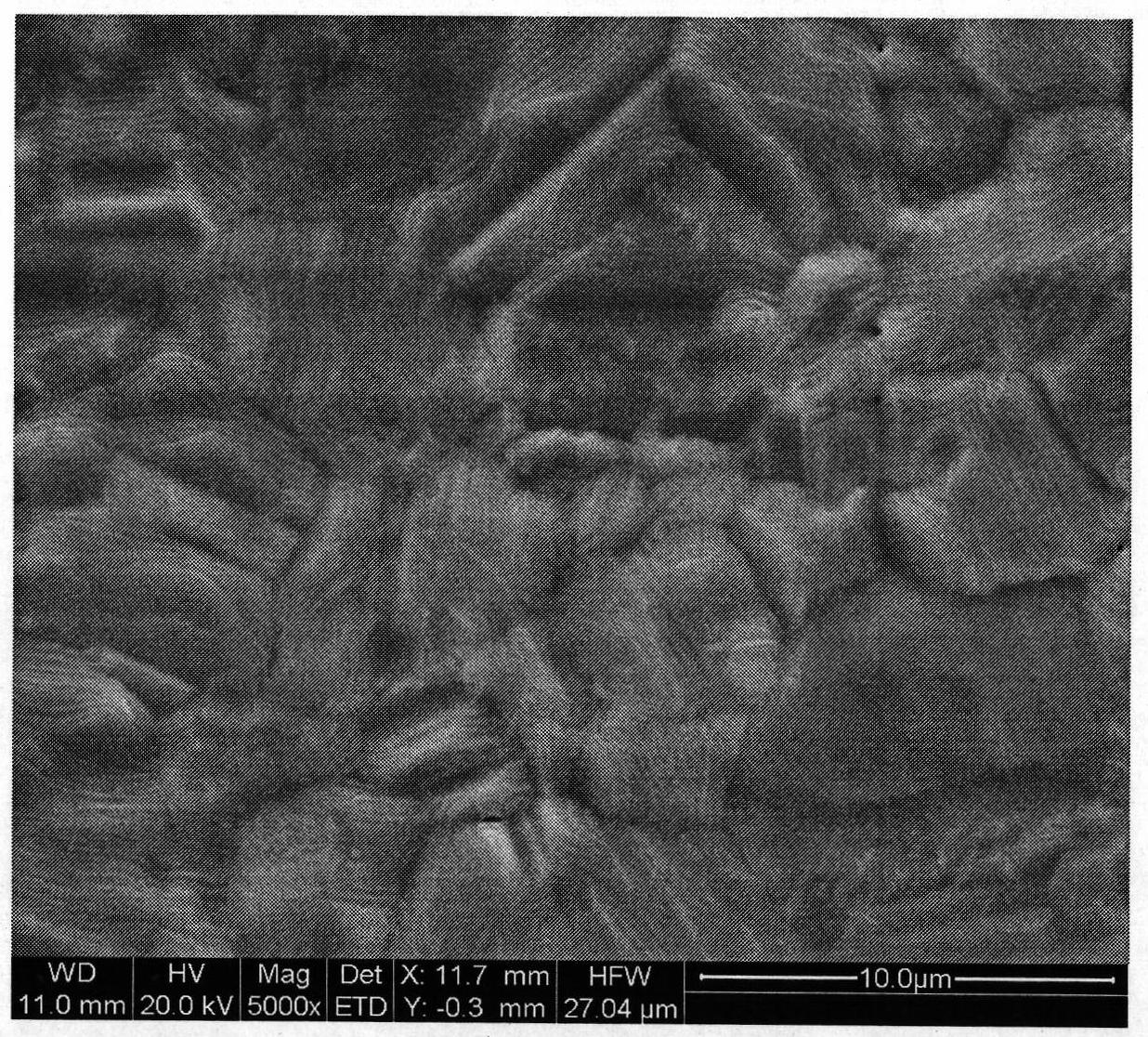

Examples

Embodiment 1

[0045] Embodiment 1: NiCoCrAlY coating is prepared on the as-cast NiCoCrAlY alloy substrate

[0046] (1) prepare the evaporating material rod, and set it aside;

[0047] The composition of NiCoCrAlY rod is nickel, cobalt, chromium, aluminum and yttrium, and its percentage by weight is 47.8% nickel, 20% cobalt, 22% chromium, 8.8% aluminum, 1.4% yttrium, the total amount of the above-mentioned components is 100%;

[0048] (2) Polish the Φ16×2mm disc cut from the above-mentioned rod with 150#, 300#, 400#, 800# sandpaper sequentially to make the surface roughness Ra<0.8. Then put it into acetone for ultrasonic cleaning for 30min, and install it on the rotating substrate frame of electron beam physical vapor deposition equipment;

[0049] (3) NiCoCrAlY feed rod is placed in the water-cooled copper crucible;

[0050] (4) Pump the vacuum chamber to the required lower than 5×10 -3 Pa vacuum degree;

[0051] (5) Set the rotational speed of the rotating substrate holder to 12rpm, a...

Embodiment 2

[0059] Embodiment 2: CoCrAlY coating is prepared on the DZ125 alloy substrate

[0060] (1) Prepare the evaporating material stick, spare

[0061] The composition of CoCrAlY material bar is cobalt, chromium, aluminum and yttrium, and its percentage by weight is 57% cobalt, 30% chromium, 12% aluminum, 1.0% yttrium, and the total amount of above-mentioned each composition is 100%;

[0062] (2) Wire-cut the Φ16 DZ125 (composition in Table 1) alloy test rod into 2mm discs and polish it with 150#, 300#, 400#, 800# sandpaper in sequence to make the surface roughness Ra<0.8. Then put it into acetone for ultrasonic cleaning for 30min, and install it on the rotating substrate frame of electron beam physical vapor deposition equipment;

[0063] Table 1 Chemical composition of DZ125 alloy (wt.%)

[0064]

[0065] (3) CoCrAlY feed rod is placed in the water-cooled copper crucible;

[0066] (4) Pump the vacuum chamber to the required lower than 5×10 -3 Pa vacuum degree;

[0067] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com