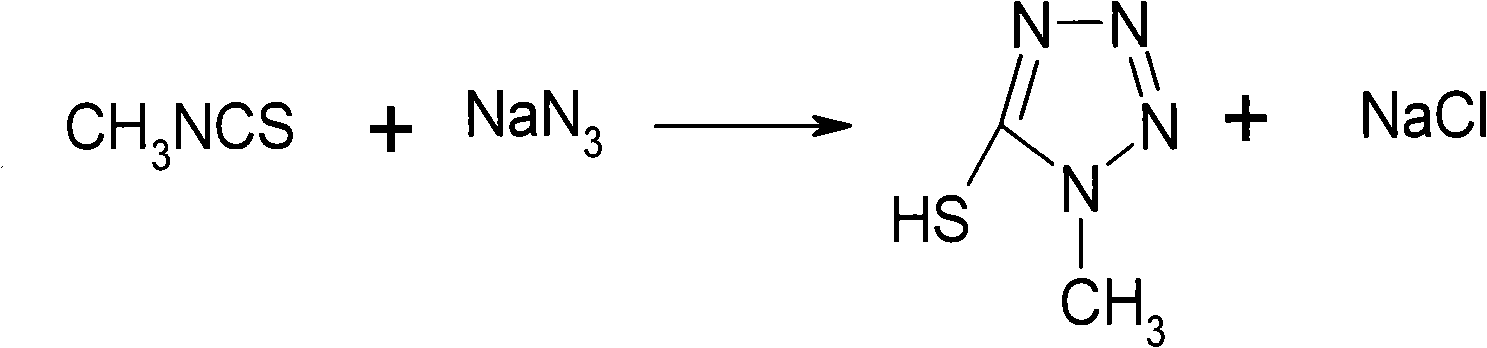

Production method of 1-methyl-5-mercapto-1,2,3,4-tetrazole

A production method and a technology for tetrazolium, which are applied in the field of chemical synthesis and preparation, can solve the problems of intractability, large recovery loss and low yield, achieve significant economic and social benefits, reduce production costs and environmental pollution, and reduce product yields. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 700L of deionized water into the reaction kettle, start stirring, add 300Kg of sodium azide, add 0.8kg of high-efficiency phase transfer catalyst tetrabutylammonium chloride, heat up to 80°C with steam, switch to circulating water to cool down, and start dripping molten 405kg of methyl isothiocyanate, control the rate of addition, and ensure that the temperature of the reaction system is around 80°C. After the dropwise addition is completed, the heat preservation reaction is carried out for 5 hours. After the heat preservation is completed, the reaction solution is transferred to the dehydration kettle, and concentrated under reduced pressure. , stop concentrating, pass circulating water to cool down to room temperature, switch to refrigerated brine and continue to cool down to -5°C, add hydrochloric acid dropwise, measure the pH value of the reaction solution, the Congo red test paper changes from red to blue as the end point, crystallize for 2 hours, and centrifuge ...

Embodiment 2

[0018] Add 700L of deionized water into the reactor, start stirring, add 300Kg of sodium azide, add 1kg of high-efficiency phase transfer catalyst 18-crown 6 ether, heat up to 70°C with steam, switch to circulating water to cool down, and start adding molten isosulfur Methyl cyanate 405kg, control the rate of addition, and ensure that the temperature of the reaction system is around 70°C. After the dropwise addition is completed, the temperature is kept for 8 hours. After the temperature is completed, the reaction solution is transferred to the dehydration kettle, and concentrated under reduced pressure. When the concentration is about half, stop the concentration After cooling down to room temperature with circulating water, switch to frozen brine and continue to cool down to -5°C, add hydrochloric acid dropwise, measure the pH value of the reaction solution, the Congo red test paper changes from red to blue as the end point, keep crystallization at -5°C for 2 hours, leave 500...

Embodiment 3

[0021] Add 1200L of deionized water into the reactor, start stirring, add 300Kg of sodium azide, add 18kg of high-efficiency phase transfer catalyst trioctylmethyl ammonium chloride, heat up to 80°C with steam, switch to circulating water to cool down, and start dropping Molten methyl isothiocyanate 405kg, control the rate of addition, to ensure that the temperature of the reaction system is around 80 ° C, after the dropwise addition is completed, the heat preservation reaction is 5 hours, after the heat preservation is completed, the reaction solution is transferred to the dehydration kettle, and concentrated under reduced pressure. , stop the concentration, pass circulating water to cool down to room temperature, switch to frozen brine and continue to cool down to -5°C, add hydrochloric acid dropwise, measure the pH value of the reaction solution, the Congo red test paper changes from red to blue as the end point, keep at -5°C After crystallization for 2 hours, 560Kg of crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com