Lithium secondary battery cathode material and preparation method thereof

A technology for lithium secondary batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the overall performance of the battery, low reversible specific capacity, and decreasing the regularity of the graphite layer, so as to improve the service life and charge and discharge. Effects of efficiency, high reversible specific capacity, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of anode materials for lithium-ion batteries

[0021] Weigh organically modified montmorillonite (Zhejiang Fenghong Clay Chemical Co., Ltd.) to be 40 mg, acetylene black (Tianjin Zhaohui Chemical Co., Ltd.) to be 5 mg, and polyvinylidene fluoride (Guangzhou Weber Chemical Co., Ltd.) to be 5 mg. Put in a mortar. Grind for 15 minutes, then add 0.4mL NMP, continue grinding for 30 minutes, coat the ground slurry on an aluminum foil, dry it in a blast oven at 60°C for 45 minutes, place the electrode material in a vacuum oven at 50 °C for 24 hours. Then, the button cell CR2430 model was cut for the electrode sheet, and the mass of the active material was weighed and set aside.

[0022] (2) Battery assembly and testing

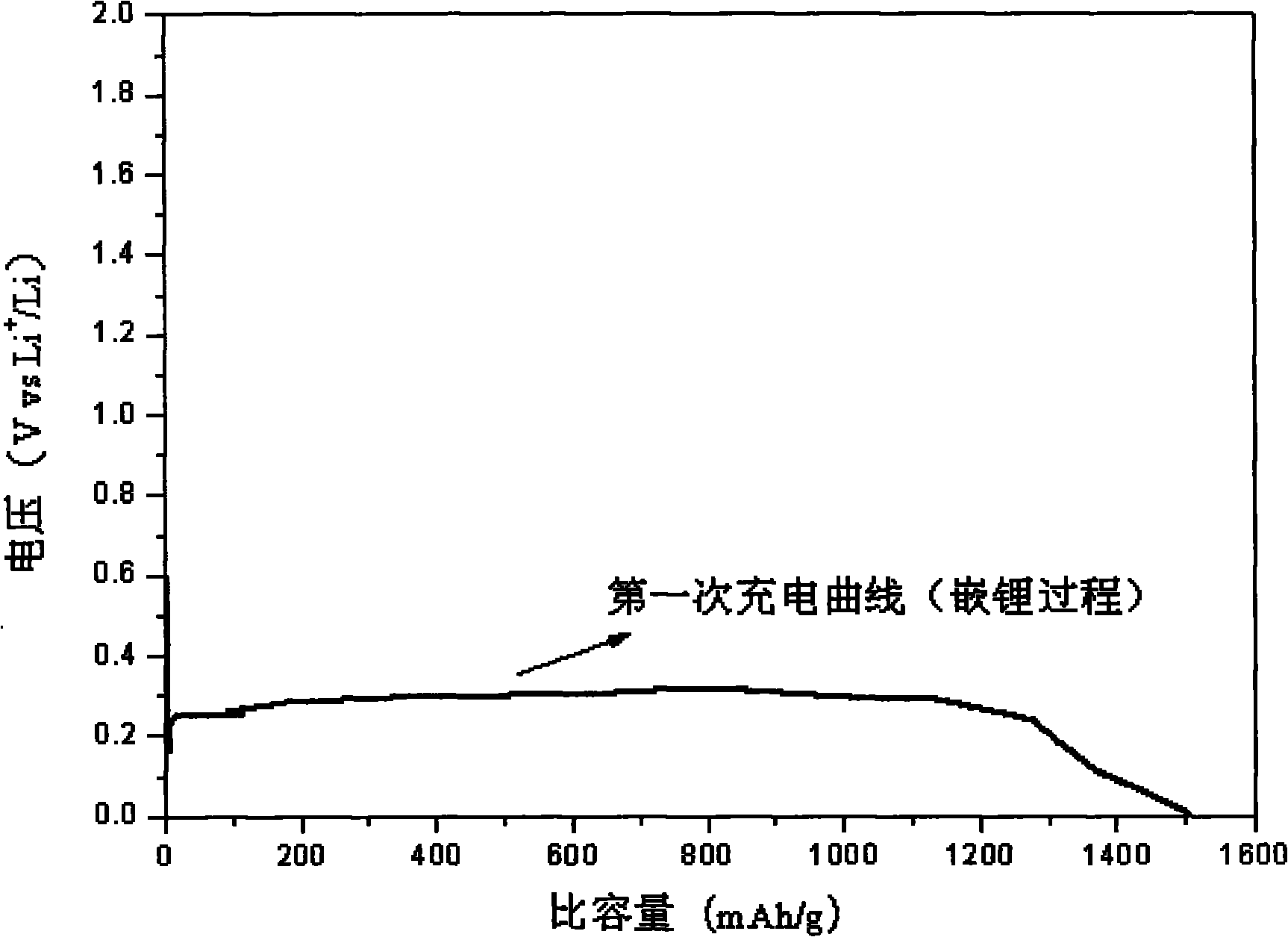

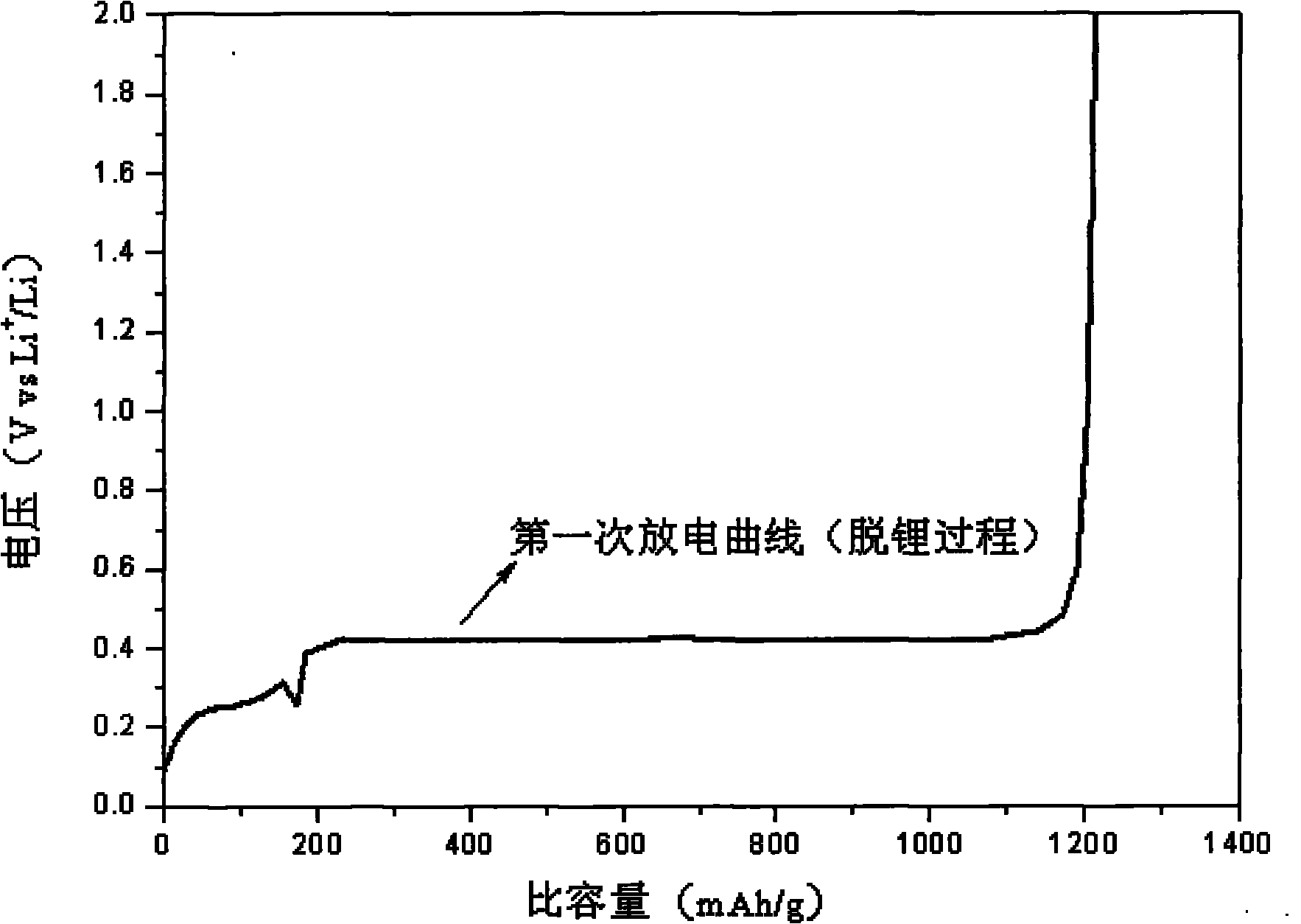

[0023] Place the cut electrode sheet in a vacuum-filled glove box filled with argon, and then assemble the battery. The electrolyte used in the battery is lithium hexafluorophosphate / ethylene carbonate-dimethyl carbonate-diethyl carbonate (L...

Embodiment 2

[0025] (1) Preparation of anode materials for lithium-ion batteries

[0026] Weigh 80 mg of organically modified montmorillonite, 15 mg of acetylene black, and 5 mg of polyvinylidene fluoride and place them in a mortar. Grind for 20 minutes, add 0.25mL NMP, continue grinding for 40 minutes, coat the ground slurry on aluminum foil, dry it in a blast oven at 60°C for 45 minutes, and place the electrode material in a vacuum oven at 50°C Temperature, dry for 48 hours. Then, the button cell CR2430 model was cut for the electrode sheet, and the mass of the active material was weighed and set aside.

[0027] (2) Battery assembly and testing

[0028] Place the cut electrode sheet in a vacuum-filled glove box filled with argon, and then assemble the battery. The electrolyte used in the battery is LiPF 6 / EC-DMC-DEC, metal lithium as the reference electrode, PP / PE / PP three-layer composite film as the battery separator. The assembled button battery was left to stand at room temperatu...

Embodiment 3

[0030] (1) Preparation of anode materials for lithium-ion batteries

[0031] Weigh 85 mg of organically modified montmorillonite, 10 mg of acetylene black, and 5 mg of polyvinylidene fluoride and place them in a mortar. Grind for 25 minutes, add 0.35mL NMP, continue grinding for 20 minutes, coat the ground slurry on the aluminum foil, dry it in a blast oven at 60°C for 60 minutes, and place the electrode material in a vacuum oven at 50°C Dry at room temperature for 24 hours. Then, the button cell CR2430 model was cut for the electrode sheet, and the mass of the active material was weighed and set aside.

[0032] (2) Battery assembly and testing

[0033] Place the cut electrode sheet in a vacuum-filled glove box filled with argon, and then assemble the battery. The electrolyte used in the battery is LiPF 6 / EC-DMC-DEC, metal lithium as the reference electrode, PP / PE / PP three-layer composite film as the battery separator. The assembled button battery was left to stand at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com