Vanadium pentoxide-lithium borate-graphene glass positive electrode material and preparation method and application thereof

A cathode material, graphene technology, applied in the field of V2O5-LiBO2-graphene glass cathode material and its preparation, can solve the problems of high price, low specific capacity, low energy density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

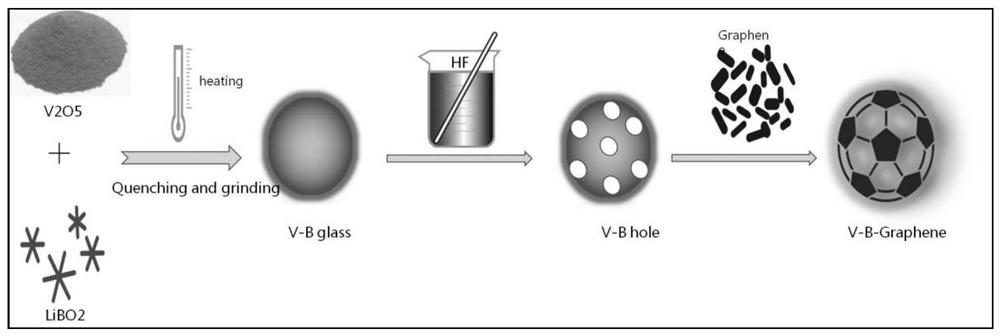

[0026] The present invention provides a V 2 o 5 -LiBO 2 -The preparation method of graphene glass cathode material, comprises the following steps:

[0027] a) V with a mass ratio of 7 to 9:2 to 3 2 o 5 and LiBO 2 Mix evenly, heat up to 700-800°C, keep warm, and quench; keep warm at 180-220°C for 8-10 hours, and ball mill after cooling to obtain a powder with a particle size D50 of less than 10 μm;

[0028] b) mixing the powder and the corrosive agent at a mass ratio of 1:1.8 to 2.3 to form pores, and then ultrasonically mixing with the flake graphene dispersion to obtain a precursor;

[0029] c) In an Ar atmosphere of 0.015-0.025MPa, anneal the precursor at 200-400°C and keep it warm for 6-9h to obtain V 2 o 5 -LiBO 2 - Graphene glass cathode material.

[0030] In the present invention, V with a mass ratio of 7 to 9:2 to 3 2 o 5 and LiBO 2 Mix evenly, heat up to 700-800°C, keep warm, and quench; keep warm at 180-220°C for 8-10 hours, and ball mill after cooling to ...

Embodiment 1

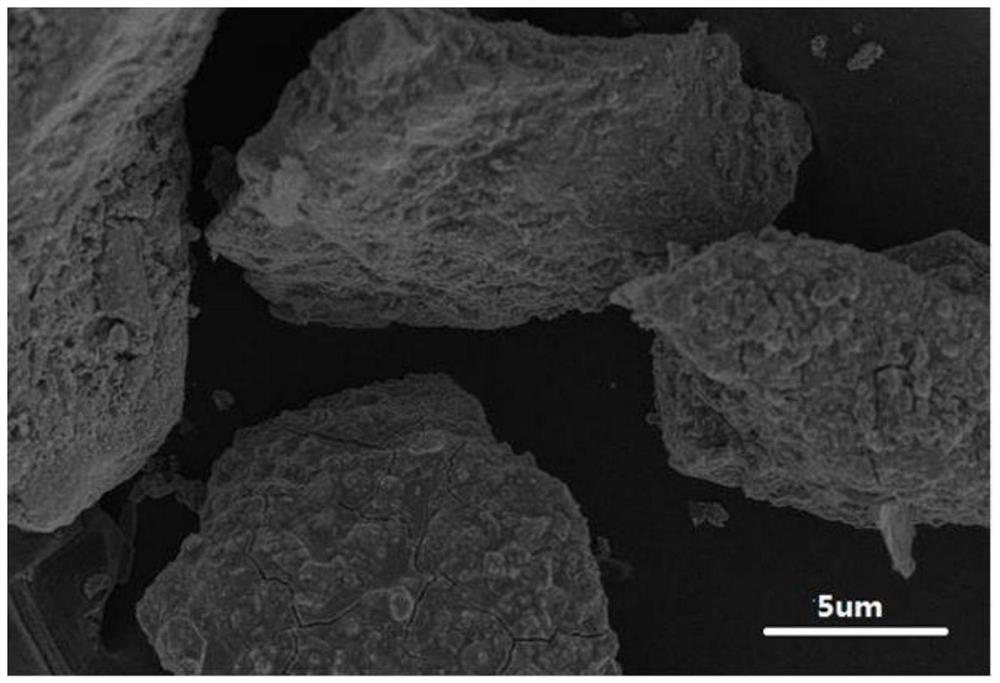

[0047] V with a mass ratio of 8:2 2 o 5 and LiBO 2 Mix evenly, transfer the obtained mixed raw materials to an alumina crucible, melt in a heating furnace, raise the temperature to 800°C at a heating rate of 10°C / min, keep it warm for 30min, pour it into an iron plate under vacuum, and cool it rapidly ( Quenching), heat at 200°C for 9 hours, then cool down to room temperature with the furnace, grind into powder, ball mill for 100min, sieve, particle size D50 is less than 10μm, and vacuum pack;

[0048] Add 10mL of 1mol / L hydrofluoric acid aqueous solution and 5g of the above-mentioned powder into a plastic beaker, mix and make holes under stirring, the stirring speed is 1000rpm, the temperature is 400°C, the time is 100min, and then add 5g with a solid content of 1%. The flake graphene dispersion was ultrasonicated at 40°C for 50min, and then dried at 140°C for 5h to obtain the precursor;

[0049] Put the precursor into a closed tubular heating furnace, pressurize Ar to 0.0...

Embodiment 2

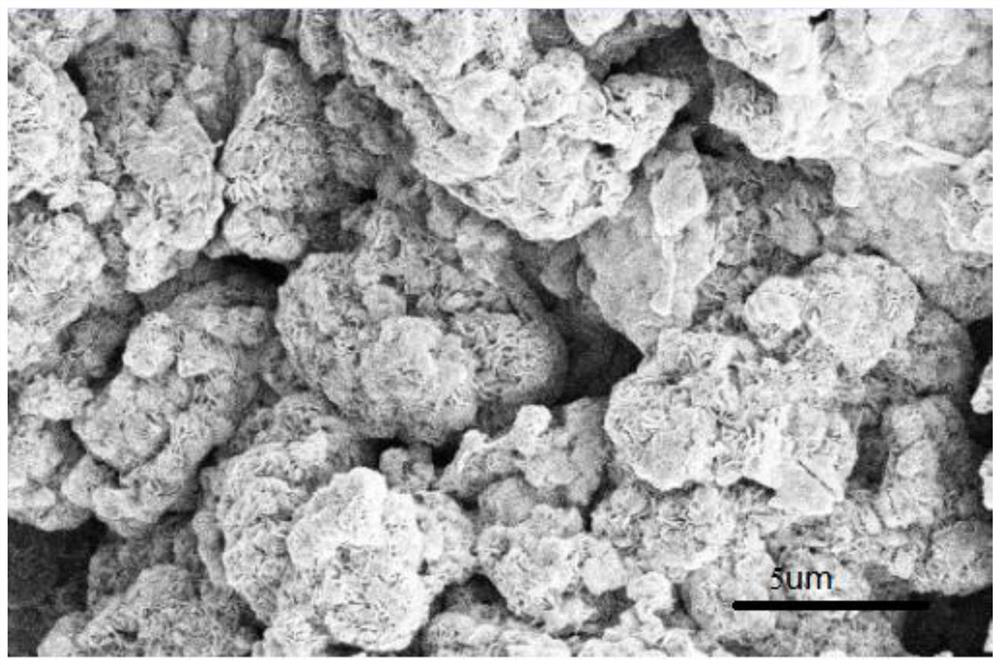

[0052] The same step as in Example 1, except that 8 g of graphene flake dispersion with a solid content of 2% was added.

[0053] image 3 V prepared for Example 2 of the present invention 2 o 5 -LiBO 2 - Scanning electron microscope image of graphene glass cathode material; from image 3 It can be seen that: V 2 o 5 -LiBO 2 -The graphene glass powder is spherical as a whole, and dense small holes appear on the surface to realize the loading of graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com